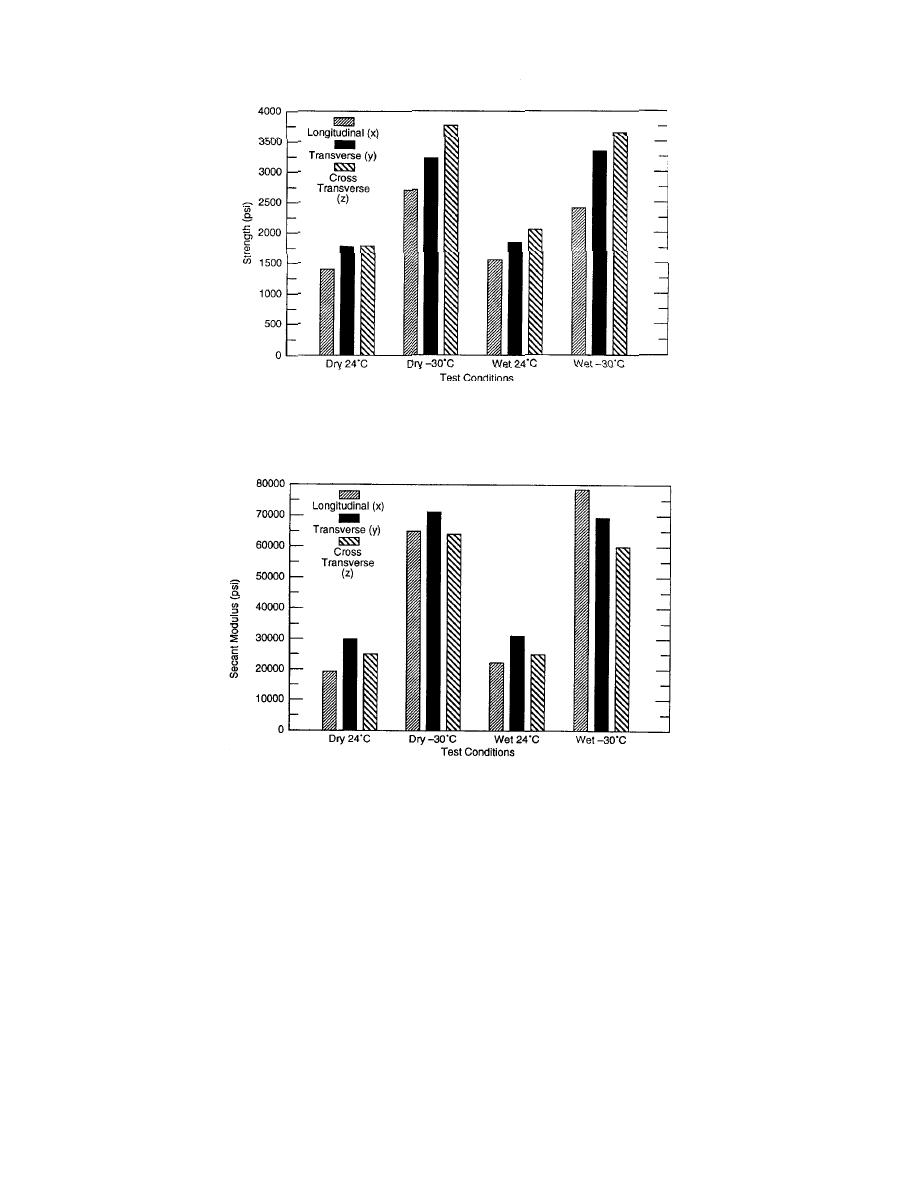

Figure 46. Compressive strength of the RPC in three axes and four

conditions: dry, wet, dry and cold (30C, 22F), and wet and cold

(30C, 22F).

Figure 47. Secant moduli of the RPC in three axes and four conditions:

dry, wet, dry and cold (30C, 22F), and wet and cold (30C,

22F).

material properties between the longitudinal and

Tension testing

the two transverse directions. However, the dif-

Since the RPCs under study were new materi-

ferences in the properties between the two trans-

als, no standard test procedures were available for

verse directions were much smaller than those in

any of the mechanical tests undertaken. For ten-

the longitudinal direction.

sion tests, it is necessary to establish that the test

The tests also showed that the material proper-

specimen fails in the uniformly tensioned area,

ties are highly temperature sensitive. Temperature

and that the effects of gripping and other stress

has a significant effect on the compressive strength

concentration factors are absolutely minimized.

of the material, regardless of the orientation and

Following a considerable amount of investigation,

moisture content. Low temperature caused a dra-

an optimum configuration for the test specimens

matic increase in the secant modulus. Moisture

was determined, as shown in Figure 48a. Figure

and orientation effects were secondary.

48b shows the specimens. A special gripping fix

33

Previous Page

Previous Page