the bonds must be simple grain boundaries with

grain-boundary grooves. Kuroiwa's (1962) Figure

9 shows bonding between polycrystalline grains,

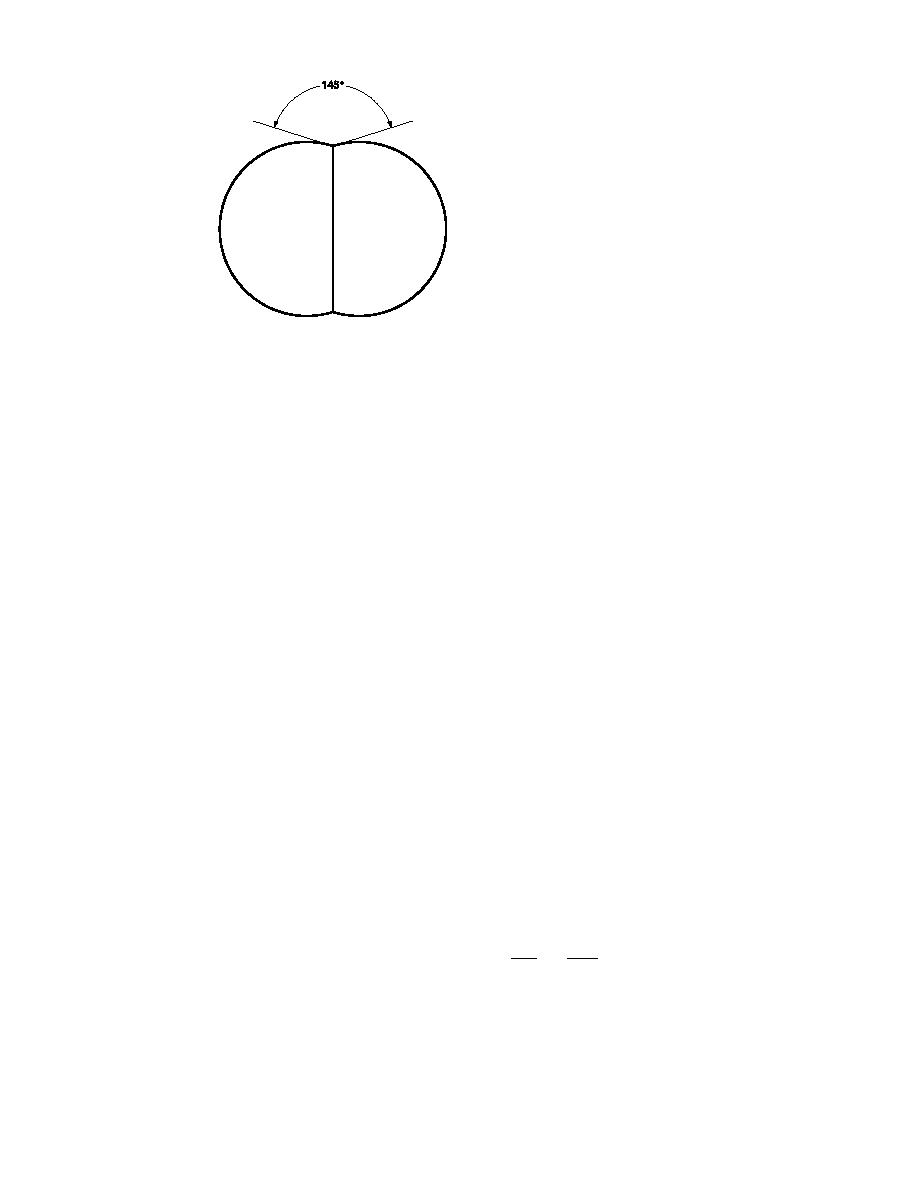

Figure 9. Equilibrium

but the actual bond appears to connect only two

form of two grains

of the crystals, one within each grain.

of ice consisting

When two ice grains consisting of a single crys-

of single crystals

tal each are joined by a bond, the equilibrium

where the grain-

form of the arrangement should be as shown in

boundary groove

Figure 9. For the old grains shown in Figure 7b,

angle is 145. Ac-

the grain-boundary groove angles are about 138

tual bonds may

and 148, close to the equilibrium value observed

not have had time

by Ketcham and Hobbs (1969). For the fresh snow

to achieve this

shown in Figure 8, the grain-boundary groove

configuration.

angle appears to be much smaller because the

bond has not yet had sufficient time to approach

the equilibrium condition. However, a closer ex-

amination of this bond could prove that the actual

Keeler (1969) found that the rate of bond growth

angle is closer to the equilibrium value.

was much greater in natural snow than predicted

Zhang and Schneibel (1995) described the sin-

by sintering theory. Although he attributed this

tering of grains joined by grain-boundary grooves.

to stresses in the snow, the effect of stress on the

They explained the imbalance of forces that oc-

thermodynamics is very small and thus it seems

curs in the grain-boundary groove before the equi-

likely to me that this is due to the presence of a

librium condition has been established; they

macroscopic temperature gradient. These are al-

assumed that the dihedral angle was fixed

ways imposed on the snow cover by environmen-

throughout the process. Sintering in their model

tal factors, and thus water vapor is driven through

was limited to grain boundary and surface diffu-

the snow. This enhanced vapor movement should

sion and expressing their results in terms of the

be much greater than vapor movement due to

diffusivity ratio of these two processes. Unfortu-

differences in curvature or stress. A much greater

nately, the values for the diffusivities are still

rate of vapor flow should cause faster bond

uncertain for ice, so it is not possible to calculate

growth, just as it causes faster grain growth

meaningful rates of bond growth based on these

(Colbeck 1983b). While the bonds must move to-

processes. Furthermore, in seasonal snow covers

ward their equilibrium shape, the rate at which

it seems likely that the shape is determined by the

the bonds grow is probably controlled by vapor-

requirement for equilibrium, but the rate is deter-

density gradients caused by macroscopic tempera-

mined by vapor flux due to the macroscopic tem-

ture gradients, not by microscopic curvature or

perature gradient. In spite of these limitations,

stress differences. Without an imposed tempera-

the ideas expressed by Zhang and Schneibel (1995)

ture gradient, depth hoar could not grow at all in

are clearly applicable to sintering in snow and, if

snow, and rounded crystals would grow much

fact, are vital to understanding what is actually

more slowly than observed (de Quervain 1958).

observed in snow. For this reason their work on

Given that the rate-limiting factor in mass flow in

surface and grain-boundary diffusion is summa-

snow is the vapor density gradient, which is con-

rized here.

trolled by the temperature profile, the classical

Surface diffusion is proportional to the gradi-

theory of sintering may have little to do with the

ent of the chemical potential, or the gradient of

rate of formation of bonds in dry snow. This prob-

curvature along the surface. As the resulting flux

ably explains why the rate of sintering has often

reconfigures the surface, the growth or decay of

been found to occur faster than is described by

the surface is given by the gradient of the flux, so

models or laboratory experiments.

2K

The basic geometries of rounded grains and

ra

=B

(2)

their bonds are controlled by phase equilibrium.

s2

t

Thus, the shape of the bond, but not its rate of

growth, can only be understood by examination

where ra is the normal vector to the surface, K is

of the equilibrium condition at the bond. Ice grains

the surface curvature, which is positive for con-

in dry snow generally consist of single crystals, so

vex surfaces, s is length along the surface, and

7

Previous Page

Previous Page