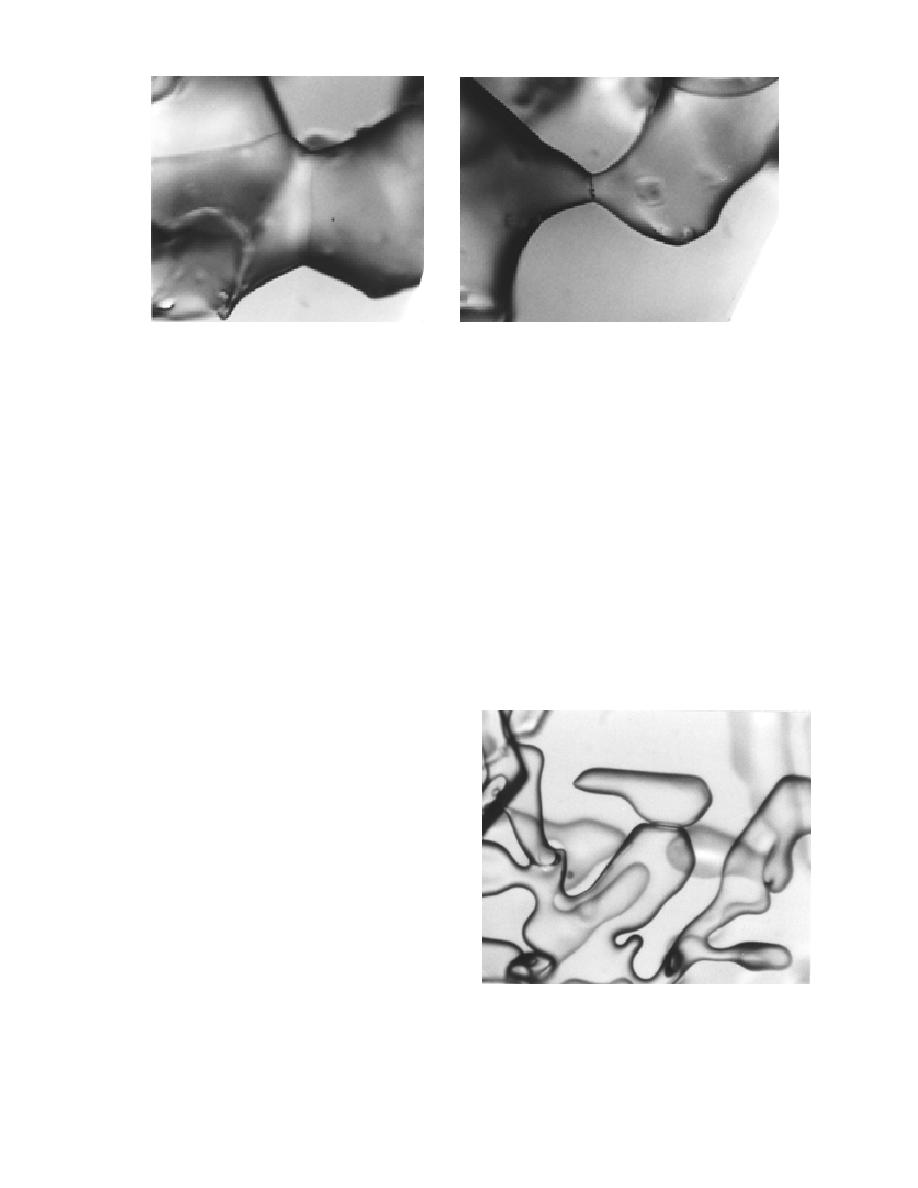

Figure 7. Snow grains stored at 24F for several years showing distinct grain-boundary grooves at the

bonds.

leading in this regard since they where made from

period of the formation of a bond when surface

sections and not from the whole grains. As dis-

diffusion, or even pressure meltingregelation,

cussed later, it is important to know if the dihe-

could occur. In fact, it makes a lot of sense to think

dral angle of about 145 is always maintained

about different mechanisms dominating during

throughout sintering, or if the angle is small ini-

different phases of bond growth, just as Alley et

tially and then increases as sintering proceeds.

al. (1982) and Wilkinson (1988) did for densifica-

This question should be answered with more mi-

tion. Ideas based on a concave curvature (Fig. 4)

croscopic observations, since its answer will de-

could dominate during the early phases when

termine how we think about the processes and

sintering is most rapid, and microphotographs

how they are modeled. For example, if an angle of

are not yet available to disprove the notion of a

about 145 is always maintained, there will neces-

simple concave bond. Figure 6 shows that one

sarily be concave curvature adjacent to the grain-

grain can be purely convex while the other has

boundary groove, at least during the initial stage

mixed curvature, and thus different processes may

of sintering. This will affect all of the processes,

operate on adjacent grains, or even on different

regardless of what they are.

parts of one grain. Figure 7 shows the nature of

grain bonds in snow stored at a low temperature

for several years: these bonds are crystal bound-

aries with grain-boundary grooves and the ap-

propriate grain-boundary groove angle for ice and

water vapor, about 145 2 (Ketcham and Hobbs

1969). Because the grains are not packed in a regu-

lar manner, part of the grain surface can be still be

concave, even at this late stage of sintering.

The formation of grain-boundary grooves is

not limited to old snow that has had a long time to

reach its equilibrium form. A fresh snow bond of

a similar nature is shown in Figure 8. In fresh

snow, the grain-boundary groove angle appears

to be much less than the equilibrium value of 145

because the bonds have just formed. The bond

grows rapidly at first as the stress imbalance at

the junction is reduced, probably with an expo-

nential decay. Kuroiwa's (1962) photographs and

Figure 8. Fresh, dry snow with newly formed bonds

my own microscopic observations suggest to me

showing a grain boundary with a grain-boundary

that the dihedral angle increases with time of

groove instead of reverse curvature.

sintering. However, his photographs can be mis-

6

Previous Page

Previous Page