old grains. Direct observations of bond growth

D δ

Γ= b b .

rate and geometry are needed during their growth.

(7)

Ds δs

They found, for example, for a dihedral angle of

DISCUSSION AND CONCLUSIONS

150, that the time to reach 50% of the final neck

shape decreased as log (Γ) increased. Thus, for each

There is a fundamental difference between wet

order-of-magnitude increase in grain-boundary

and dry snow since liquid water causes major

diffusivity, there is an increase of a factor of two

reconfigurations of both grains and bonds. Within

to five in the rate of sintering due to the removal

the wet and dry snow categories there are also

of material from the grain boundary and deposi-

two important divisions: wet snow at low and

tion of that material on the free surfaces.

high liquid contents and dry snow at low and

While this theory ignores sublimation, crystal-

high growth rates. Wet snow is cohesionless and

lographic differences, and the role of the macro-

slushy at high liquid contents because the grain

scopic temperature gradient in determining the

boundaries are unstable against pressure melt-

rate of sintering, at least it includes the role of the

ing. However, wet snow is well-bonded at low

dihedral angle and grain-boundary diffusion. Per-

liquid contents where ice-bonded clusters form.

haps its greatest limitations are the assumptions

A transitional form of snow, meltfreeze grains,

of a constant dihedral angle and an adiabatic en-

can be either wet or dry. These amorphous,

vironment.

multicrystalline particles arise from meltfreeze

cycles. They are solid within and well-bonded to

Faceted grains

their neighbors.

Faceted grains grow rapidly due to high tem-

Rapidly growing grains in dry snow lack bond-

perature gradients and low densities. They have

ing because they consume the existing grains, they

long been of interest because they are associated

are large, and they grow rapidly. However, strong

with low strength and avalanche release. In 1973,

bonds form among rounded grains, and they grow

de Quervain proposed that grains situated at spe-

slowly. Their growth processes and geometry have

cific sites would preferentially grow more rap-

probably been misunderstood, even though this

idly. This includes "end grains" that are not

is the most studied case of sintering in snow. The

connected at their lower end and thus point down-

bonds are usually described as necks with a con-

ward into the upward-moving stream of vapor

cave geometry as in most studies of sintering of

being driven by the temperature gradient (Fig.

other materials. However, this geometry would

11). Without being connected at their lower ends,

not seem possible for a crystalline material be-

they grow rapidly, especially if there is a large

cause the equilibrium form of the crystal requires

distance between the end grain and the grain be-

the presence of a grain-boundary groove at the

low it. Furthermore, because they are not con-

crystalline boundary.

nected at the bottom, they fail to form a bond

In the past it has been assumed that the reverse

there. This is one reason why, during a major

geometry causes the migration of water molecules

recrystallization, where the rounded grains are

to the neck by one of many possible processes; the

replaced by faceted grains, the bond density of

dominant mechanisms were identified by the ob-

the new grains is low compared with that of the

served dependence on time. Kingery (1960) first

applied this approach to ice; he concluded that

the bonding was due to surface diffusion. How-

Cold

ever, the coefficient of surface diffusion required

was very high, and although this might be ex-

plained by a highly mobile surface layer, this idea

remains to be convincingly demonstrated.

Kuroiwa (1962) concluded that volume diffu-

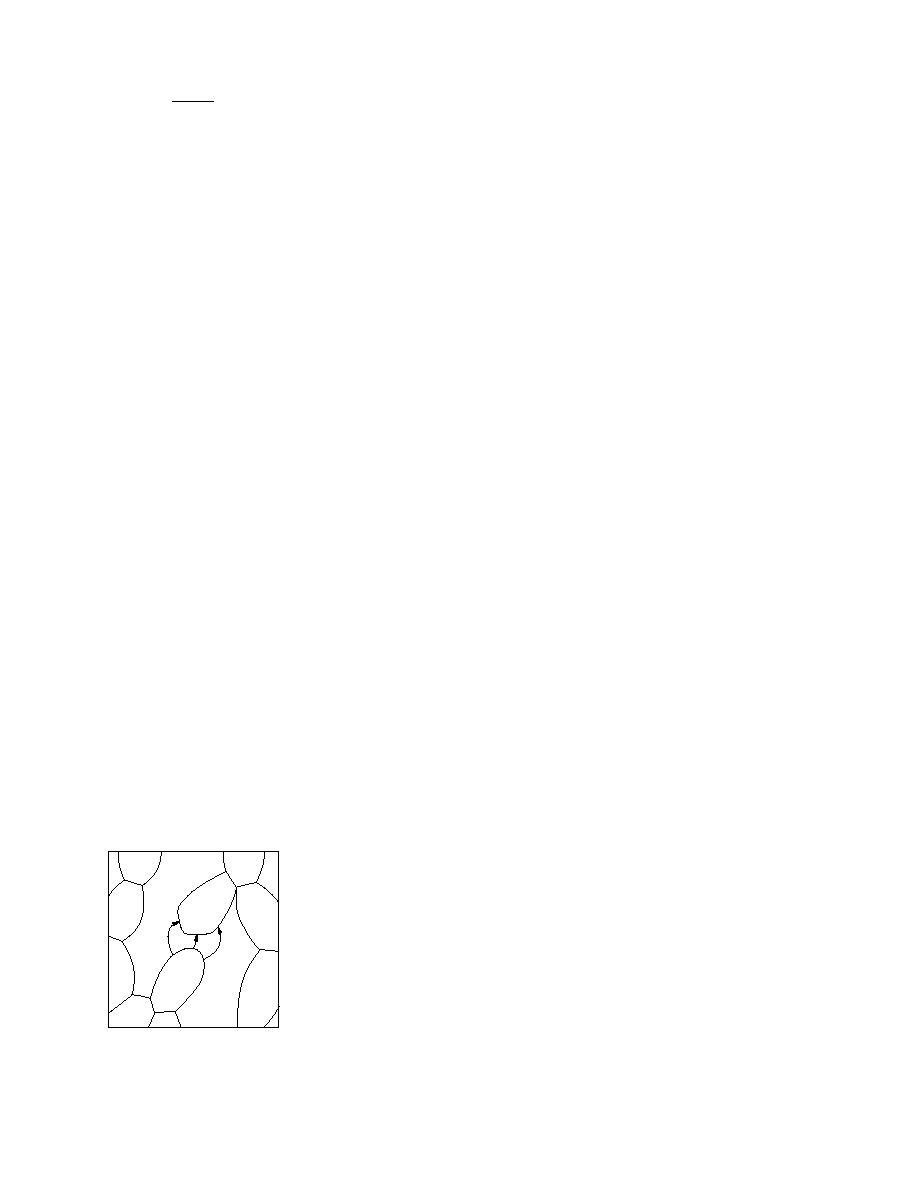

Figure 11. End grain

sion was the dominant process, but Hobbs and

pointing downwards

Mason (1964) believed that sublimation, transfer

into the upward-moving

through the vapor phase, had to be the dominant

stream of vapor as sug-

mechanism. The vapor transfer mechanism has

gested by de Quervain

since received wide support and was supported

(1973).

by the strength tests of Ramseier and Keeler (1967).

Warm

9

Previous Page

Previous Page