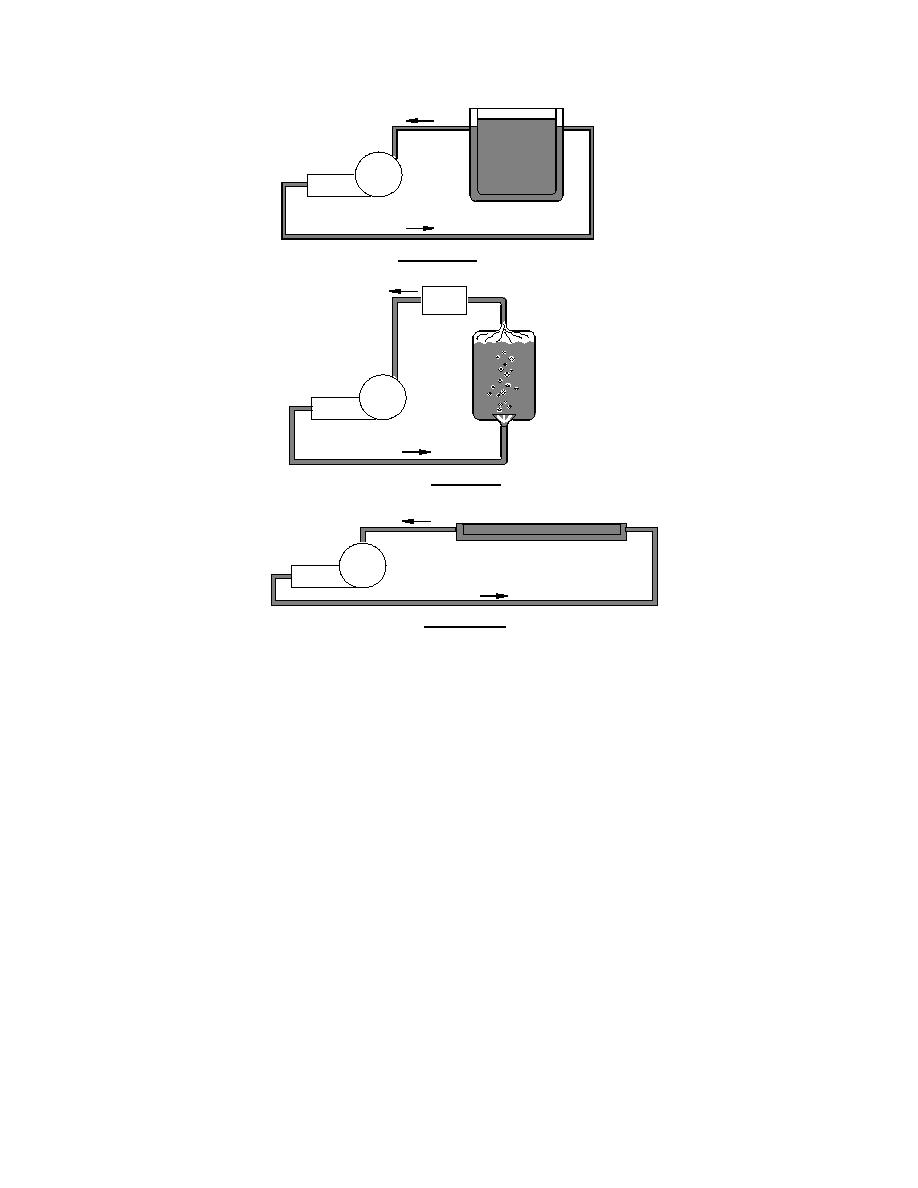

Sludge

Refrigerator

a. Bulk Freezer

Gas

Liquid

Gaseous Refrigerant

Sludge

(bubbles)

Refrigerator

b. Crystallizer

Sludge

Refrigerator

c. Layer Freezer

Figure 2. Conceptual sketches of three sludge freezing devices.

energy efficient than bulk freezing. However, this

Crystallizers

process has yet to receive widespread application

Instead of freezing sludge into a solid mass,

because of explosion hazards and the difficulty in

sludge can be frozen into a slurry of concentrated

recovering all the butane.

solids and pure ice crystals. This is done by mix-

Egan and Davis (1982) constructed a pilot-

ing the sludge at a temperature below the freez-

scale freeze crystallizer and tested its effective-

ing point. The slurry of ice crystals and solids is

ness on black liquor from the kraft pulp-manu-

then sent to a separator where the ice crystals are

facturing process. They choose this process over

washed with a portion of the melted ice crystals.

evaporation because it is less corrosive, produces

This process is called freeze crystallization or

less volatile compounds, and is potentially more

freeze concentration. It has been used commer-

energy efficient. Their tests demonstrated that a

cially for several years in concentrating fruit

15% black liquor can be concentrated to approxi-

juices, milk, beer and other liquids for human

mately 30% solids. In spite of this successful dem-

consumption. It is also a proposed method for

onstration they were not able to find a commer-

desalting seawater.

cially made, large freeze crystallizer. Because of

Randall et al. (1975) and Randall (1978) pro-

this limitation, they concluded that the pulp and

posed freezing sludge by mixing it in a crystalliz-

paper industry should not proceed any further,

er with a refrigerant such as butane. They claim

but instead keep abreast of new developments of

that this method results in better conditioning

this technology.

and supernatant quality than solid freezing. Also,

Knocke and Trahern (1989) investigated both

they conclude that the cost of this process is more

bulk freezing and crystallization on conditioning

competitive with conventional dewatering pro-

cesses because direct contact freezing is more

chemical and biological sludges. They found that

3

Previous Page

Previous Page