A Device for Mechanical FreezeThaw Conditioning of Alum Sludge

C. JAMES MARTEL, ROSA T. AFFLECK AND MELINDA L. YUSHAK

INTRODUCTION

tation costs. Thickened alum sludge produced at

Background

the plant typically contains only 2% solids (98%

Disposal of alum sludge can be a major con-

water). Therefore, some method of dewatering is

cern for water treatment plants, including those

needed before alum sludge can be placed in a

at military installations. The traditional practice

landfill or land applied.

of discharging the sludge directly into a nearby

Alum sludge is widely recognized as one of

stream is becoming less acceptable because these

the most difficult sludges to dewater. About 40%

discharges can violate state stream standards.

of the water is chemically bound to the particles,

Discharging the sludge into a sewer line is often

which is difficult to remove by conventional

used as an alternative. However, many plants are

methods such as vacuum filters, belt presses or

unable to use this alternative because they are not

centrifuges. With the aid of expensive polymers,

located near a sewer line or the treatment plant is

these processes may be able to increase the total

unable to accept their discharge.

solids content up to 20%. However, this is not

Because of the restrictions to stream and sewer

usually the case, and often the sludge is not dry

discharges, many water treatment plants have

enough to meet landfill requirements.

turned to landfilling or land application as dis-

In contrast to conventional dewatering meth-

posal methods. Most landfill regulations require

ods, freezethaw conditioning followed by grav-

a minimum of 20% solids and no evidence of free

ity filtration can easily dewater this sludge with-

flowing liquid. Volume reduction prior to land

out polymers. The process of freezethaw condi-

application is often necessary to reduce transpor-

tioning changes the sludge from a suspension of

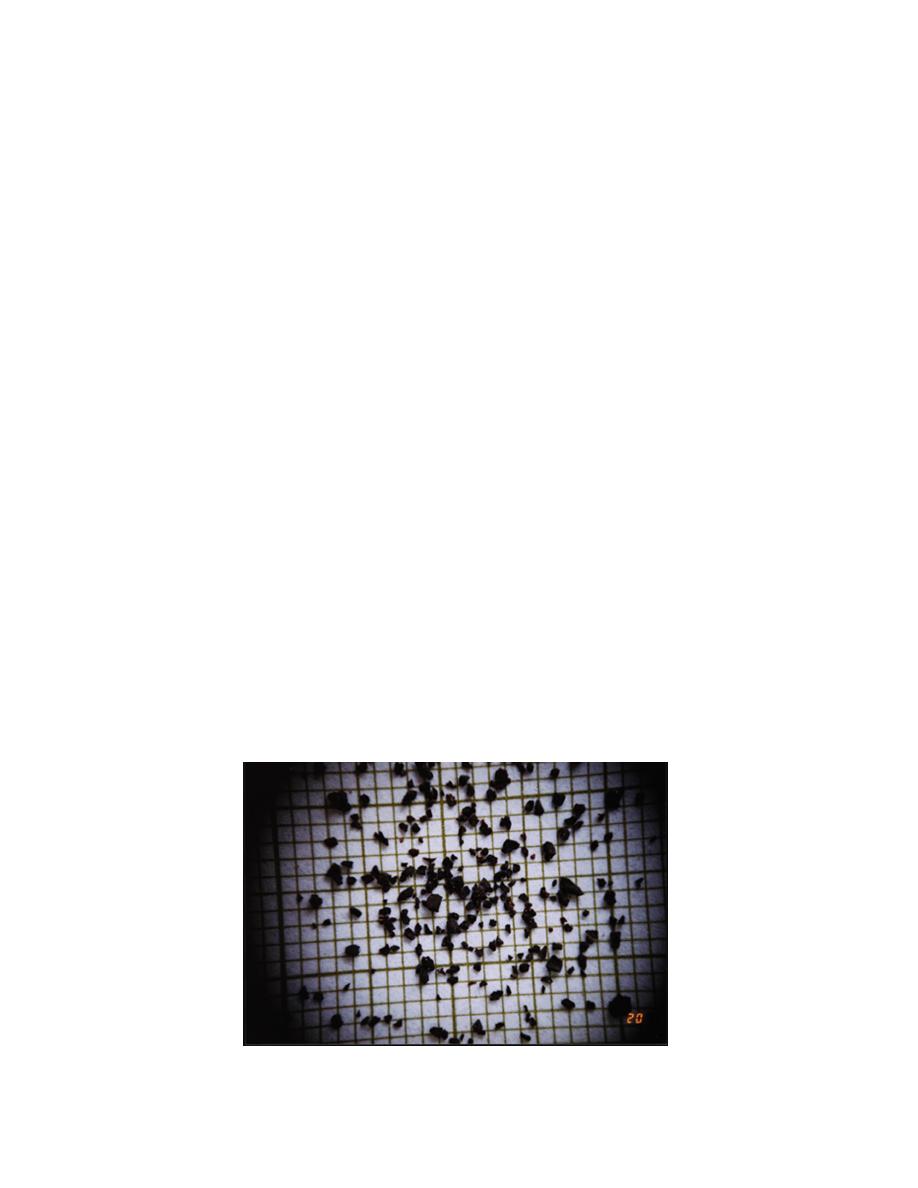

Figure 1. Sample of freezethaw-conditioned alum sludge on a 1.0-

mm-square grid.

Previous Page

Previous Page