late the small deformation assumption of the

18

derivation. At d/w = 4, the critical extension

16

is about 10%, which occurs at a critical stress

14

approximately equal to the modulus E. At

12

higher d/w values, the critical values become

10

lower. Using this information, it is possible

8

to attribute some seal failures, e.g., some of

6

the "cohesive" failures observed in butt joint

4

seals with high d/w values, to the elastic in-

2

stability mechanism.

0

1

2

3

4

5

Shrinkage or

d/w

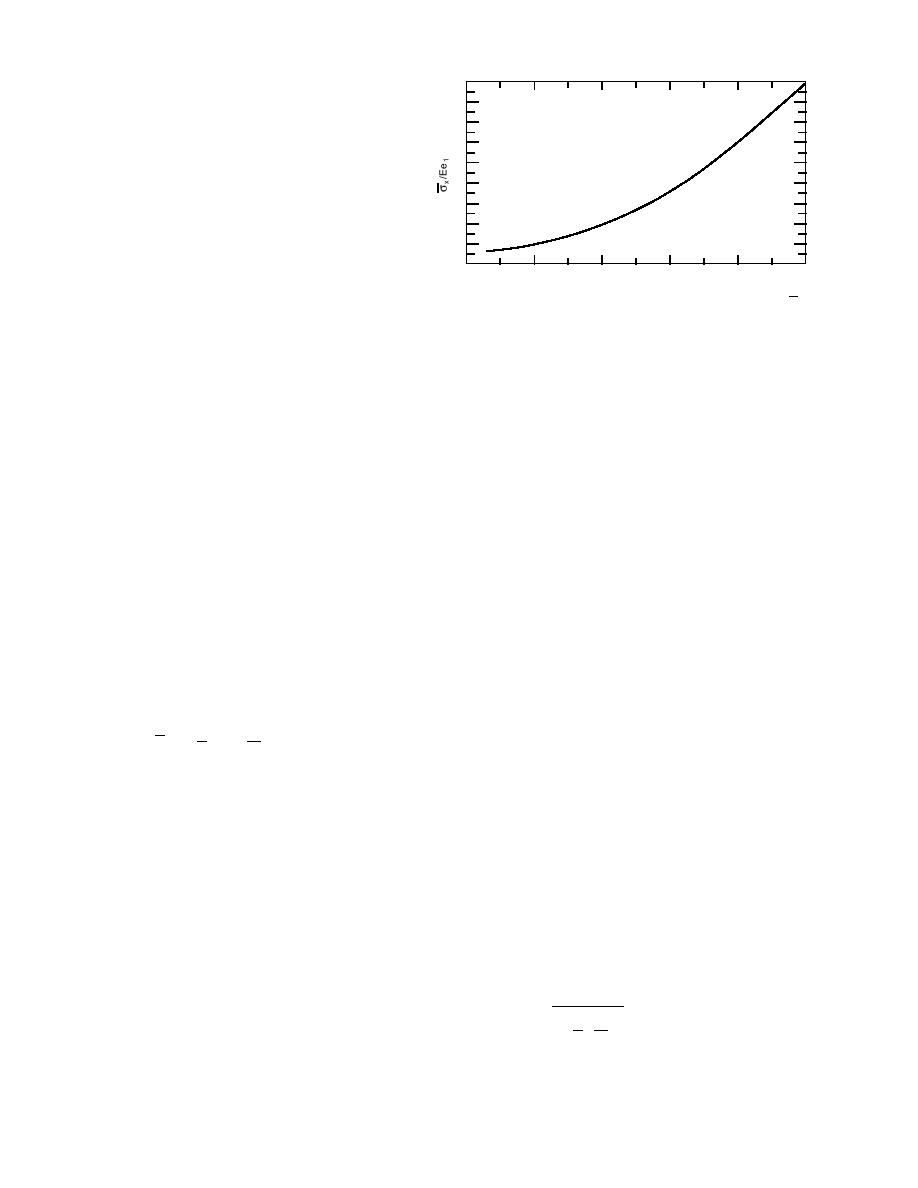

Figure 8. The nondimensionalized average normal stress σx /

expansion stresses

Using a superposition of solutions, Gent

E divided by the constrained strain e1, as a function of the

(1974) demonstrated the use of the nominal

depth-to-width ratio d/w.

stressstrain relations of bonded rubber struc-

tures to evaluate interface stresses generated

found by following Gent's procedure. Gent sug-

by the shrinkage of the rubber. Gent suggested

gested that these stresses could be superimposed

that prediction of the interface stresses caused by

with stresses generated by the joint movement in

thermally induced volume changes would be an

order to evaluate their significance.

application of the technique. For example, Gent

suggested that interface stresses generated after a

rubber structure is formed and bonded at an el-

SHEAR LOADING

evated temperature could be predicted. Using the

small deformation, nominal stressstrain relation

Rivlin and Saunders (1949) studied the effect

for a rubber block in a plane strain configuration,

of shape on the shear behavior of rubber cylin-

the prediction of stresses generated during the

ders bonded at their ends. In particular they ana-

cooling of a hot-applied seal would be a specific

lyzed the problem in which one end of a cylinder

example of this suggested application.

is displaced parallel to the other. They demon-

Following Gent's analysis procedure, when

strated by experiment and theory that, when the

there is no joint movement, and when the seal, if

diameter-to-height ratio of the cylinder is rela-

unconstrained, would otherwise extend or com-

tively small, the actual deformation can be con-

press homogeneously by e1 = ∆w/w due to shrink-

sidered to be made up of a component due to

age or expansion, the following expression for

bending in addition to a component due to shear.

the average, normal interface stress applies.

For cylinders where the bending deformation is

significant, Rivlin and Saunders suggested the

2

d

2

σx = - 2 + Ee1 .

use of an apparent shear modulus Ga to describe

(11)

w

3

the combined deformation behavior. Their analy-

sis can be applied to the problem of the shear

e1 must be known in order to evaluate the stress.

loading of a long, rectangular joint seal, as indi-

For volume changes due to temperature changes,

cated by the analysis of long, bonded rubber blocks

e1 can be related to the coefficient of linear ther-

by Lindley (1967) and Gent and Meinecke (1970).

mal expansion of the material, α, by e1 = α∆T,

Neglecting inertial effects, the problem corre-

where ∆T is the temperature change. When α

sponds to the transverse shear displacement of a

should be treated as a function of temperature, an

pavement joint seal by traffic loading. The geom-

etry of the seal, and the shear and bending defor-

The normal stress of eq 11, divided by Ee1, is

mations, are illustrated schematically in Figure 9.

illustrated in Figure 8 as a function of the depth-

For the joint seal geometry, the apparent shear

to-width ratio of the seal. The figure indicates

modulus derived by Rivlin and Saunders has the

that, as expected, the average normal stress in-

form

creases dramatically with d/w for a given material

G

and constrained strain.

Ga =

1 w 2

(12)

1+

d

and ty (y) for a constrained strain e1 could also be

3

7

Previous Page

Previous Page