in eq 1 originate, respectively, from solutions to

4 1 d 2

Ea = + E

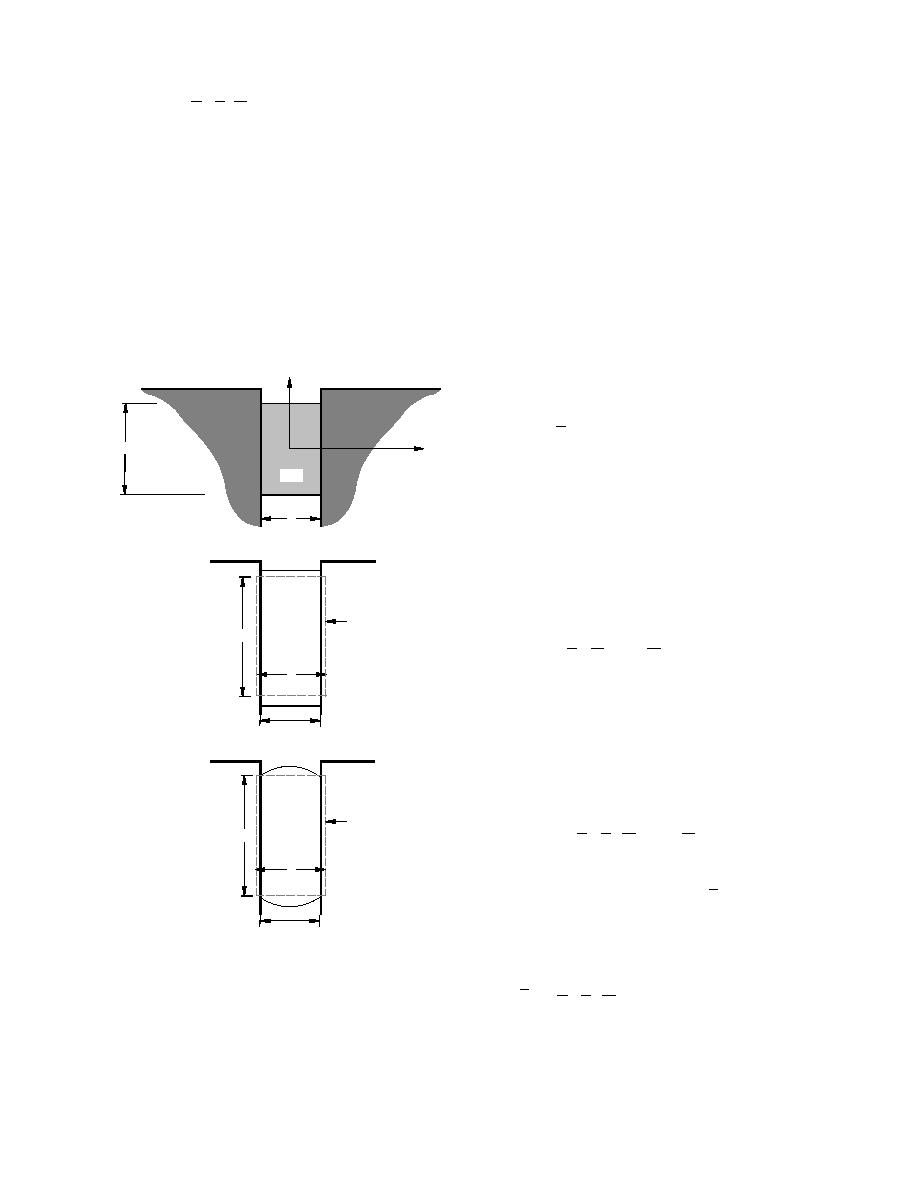

(a) a plane strain deformation in which the mate-

(1)

3 3 w

rial is free to slip on the bonded interface and to

deform homogeneously in the section, while re-

where E is the Young's modulus of the sealant,

maining constrained in the long direction, and (b)

and d and w are the depth and width of the seal

a subsequent inhomogeneous shear deformation

within the joint, respectively, as illustrated in Fig-

that restores the material of the bonded interface

ure 2a. In the literature of building and pavement

to the bonded position. These deformations are

seals, d/w is often called the shape factor of a seal.

depicted schematically in Figure 2, in parts b and

The term "apparent" was used by Gent and

c, respectively. The material is assumed to be in-

Lindley to distinguish the bonded extension or

compressible, i.e., it is assumed that there is no

compression deformation as an inhomogeneous

volume change during deformation. For the in-

structural deformation and to refer to the nomi-

homogeneous shear deformation, it is assumed

nal stress and strain of the structural response in

that planes parallel to the bonded surface remain

explicit contrast to the homogeneous stress and

plane, and that planes normal to these distort to

strain of a material property test. The two terms

form parabolas in the cross section. The solution

to the homogeneous deformation problem (a) is

y

the uniform normal stress, σx1, i.e.,

4

σx1 =

Ee

(2)

3

d

x

where e = ∆w/w is the joint extension or compres-

sion, i.e., the nominal strain of the seal, ∆w is the

Substrate

Seal

total joint movement in the x direction, and x

refers to the coordinate axis of Figure 2. The solu-

w

tion to the shear deformation problem (b) is a

a

hydrostatic pressure distribution, p(y), that varies

with the joint extension or compression, and along

the interface of the seal in the y direction, accord-

ing to

Undeformed

1 d 2

y

2

d

Configuration

()

p y = - 2 Ee

.

(3)

2 w

w

w

(See Chaloub and Kelly [1991] for an illustrative

derivation of the governing equation that p(y)

w + ∆w

satisfies.) A normal stress distribution, σx2 (y), is

b

in equilibrium with this pressure. The total nor-

mal stress distribution is found by the superposi-

tion of the stresses σx1 and σx2 (y), i.e.,

4 1 d 2

y

2

σx (y) = + - 2 Ee

Undeformed

d

(4)

Configuration

3 2 w

w

w

where σx is the total normal stress. The average of

this stress, i.e., the nominal stress σx , is found by

integrating σx (y) over the area d 1 of the inter-

w + ∆w

face and dividing by this area. The nominal stress

c

strain relation that follows is

Figure 2. (a) Original butt joint seal configuration,

4 1 d 2

(b) homogeneous deformation, and (c) final, inhomo-

σx = + Ee

3 3 w

geneous deformation, corresponding to solution of

(5)

Gent and Lindley (1959) for the compression of bonded

= Eae .

rubber blocks.

3

Previous Page

Previous Page