of measurements of the modulus of elasticity as a

1010

function of temperature for sealant materials, and

a.

in recognition of the incompatibility of such data

10 9

with movement capability-based design calcula-

tions, this paper presents a review of simple engi-

10 8

neering mechanics-based analysis techniques for

the structural design of rubber materials subjected

10 7

to tension, compression, and shear loading in long

rectangular joint seal configurations.

10 6

Solutions and techniques described by Rivlin

and Saunders (1949), Payne (1956), Gent and

Lindley (1958, 1959), Gent (1974), and Gent et al.

10 5

100 80 60 40 20

0

20

40

60

80

100

(1974), for rubber materials that can be consid-

1010

ered incompressible under hydrostatic loading,

are summarized here and in some cases extended

b.

10 9

to the plane strain configuration of a joint seal.

Previous reviews of these solutions, and of the

10 8

corresponding engineering practice in general,

have been presented by Payne and Scott (1960),

10 7

Lindley (1967), Gent and Meinecke (1970), Gent

(1978a, b), and Stanton and Roeder (1982). Recent

10 6

examinations and extensions of these solutions

have been presented by Chaloub and Kelly (1991).

10 5

A design example illustrating use of solutions

10 4

from Payne (1956) and Gent and Lindley (1959) is

100 80 60 40 20

0 20 40 60

80 100 120 140

Temperature (C)

shown in Appendix A.

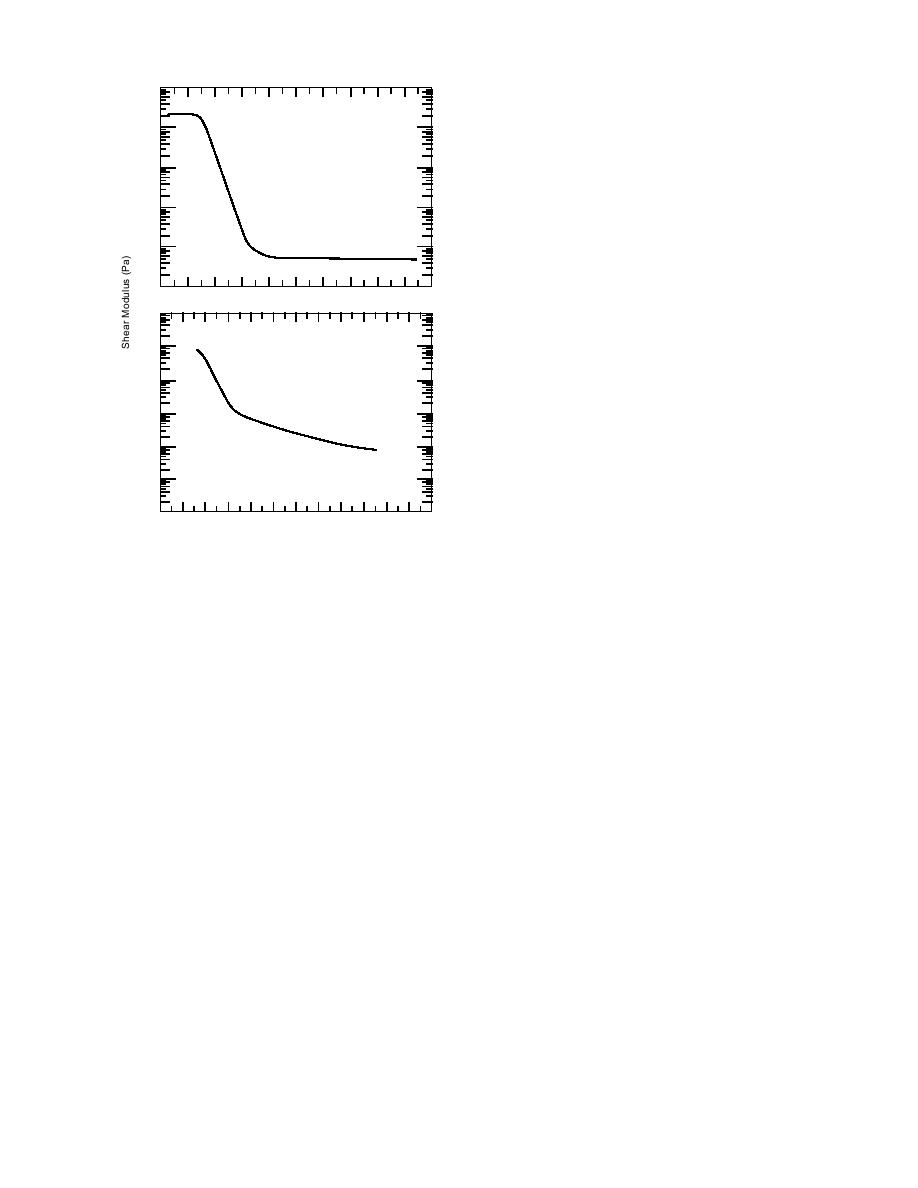

Figure 1. Real part of shear modulus G as a function

of temperature T for (a) a natural rubber and (b) a

EXTENSION AND

polysulfide sealant, from 50-Hz harmonic loading

COMPRESSION LOADING

tests (Nashif and Lewis 1991).

Gent and Lindley (1959), using small deforma-

tion, linear elasticity theory and realistic assump-

could make similar suggestions about the rubber

tions regarding structural deformations, gener-

subjected to slower loads from modulus vs. tem-

ated solutions for the stress distribution in bonded

perature results of quasi-static loading tests, which

rubber blocks during compression of the blocks.

are also conventional thermal analysis tests.

From these solutions they obtained expressions

Lewandowski et al. (1992) have demonstrated the

for the nominal stressstrain relations of the

measurement and usefulness of such data for

blocks. Payne (1956) and Gent and Lindley (1959)

pavement sealants.

also suggested approximate relations for the cor-

It is easy to envision the potential practicality

responding large deformation problem. These and

of such information for the selection of cold cli-

other solutions described here for a block in a

mate joint sealants. For example, a designer could

plane strain configuration are directly applicable

use modulus vs. temperature data of the candi-

to the extension and compression of long, formed-

date sealants together with climatic temperature

in-place, rectangular butt joint seals, and can be

data for the region of interest, and make a selec-

presented as such with only slight modification

tion using a rationale that incorporates a severe

of terminology.

winter design temperature. This is in contrast to

current practice, which typically utilizes standard

Shape factor, modulus

bond tests of model seal structures at a given low

of elasticity, and

temperature (e.g., ASTM 1991c, d), but which does

apparent modulus

not, in general, reveal explicitly the temperature

The apparent modulus of a butt joint seal in

range at which the model seal or the sealant ma-

extension or compression was given by Gent and

terial stiffens. In recognition of the potential uses

Lindley as

2

Previous Page

Previous Page