ing conditions are encountered in clays and me-

Because these relationships were derived from

dium- or high-plasticity soils, we recommend that

tests on a non-plastic fine sand (unified soil clas-

algorithms designed to treat surface slipperiness

sification SM) (Fig. 16), and limited tests on other

(Willoughby et al. 1991) be implemented in fu-

sandy soils indicate the same general trends, we

ture versions of NRMM/CAMMS. Continuing

feel confident applying them to the following soil

research is aimed at completing the definition of

types:

f and g for more soil types and wetness conditions.

SW: Well-graded sands, gravely sands, little

or no fines

SP: Poorly graded sands, gravely sands, little

or no fines

SPEED MADE GOOD

SM: Silty sands, sand and silt mixtures.

It is also reasonable to extrapolate beyond the range

The time to get from one point to another, or

of test soils to other soils of similar mechanical

speed made good, is a function of many vehicle/

operator and terrain/environment variables. Some

behavior, such as other sands (SC), gravels (GW,

GP, GM, GC) and silts (ML). We don't advise that

reduction in speed occurs as a wheel or track slips.

they be applied to clayey soils or highly plastic

Making the assumptions that

For a vehicle moving at a constant velocity

soils since the behavior of the soil, and there-

on level terrain the traction generated must

fore its influence on traction and motion resis-

equal the total motion resistance,

tance, is likely to be quite different. When thaw-

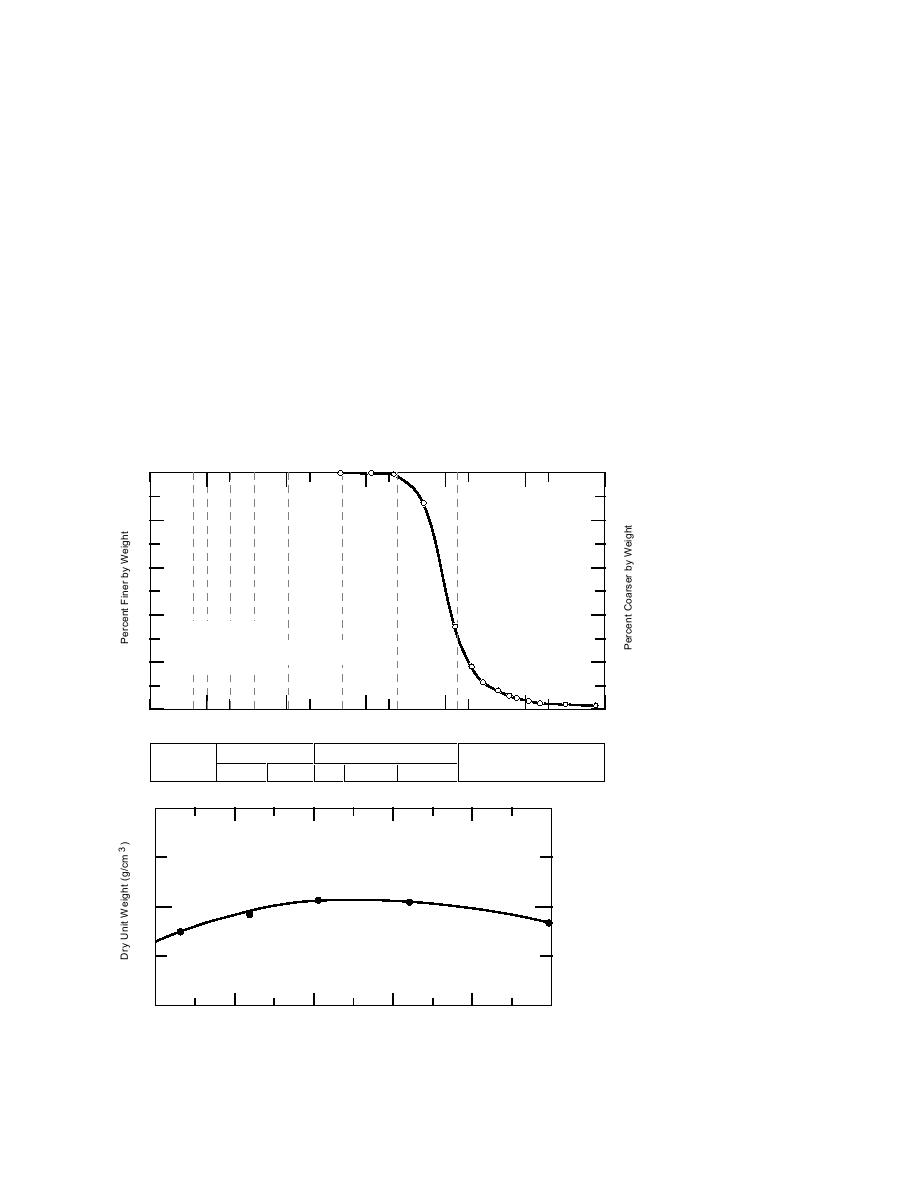

Hydrometer

U.S. Standard Sieve Numbers

6" 4"

2"

1"

10

40

200

3/8"

100

0

20

80

60

40

40

60

Lebanon Sand (SM)

Liquid Limit: 20

Specific Retention Water Content: 12 - 14%

20

80

Specific Gravity: 2.71

100

0

100

10

1

0.1

0.01

0.001

Grain Size (mm)

Gravel

Sand

Cobbles

Silt or Clay

Coarse

Fine

C'rse

Medium

Fine

a. Grain size distribution.

2.0

CE-55

Modified Proctor

1.8

b. Soil compaction curve.

Figure 16. Characteristics of

1.6

8

10

12

14

16

18

Lebanon sand.

Water Content (%)

14

Previous Page

Previous Page