atmospheric conditions such as relative wind speed and

direction, change. Thus, it is conceivable that ice may

be growing on some portions of the superstructure,

while on other areas it may be eroding (Ryerson 1995).

In addition, depending upon ship size, spray delivery

Deck

rates, and atmospheric conditions, only one, two, or all

spray

three of the zones may be found at any one time on the

ship. Often, however, thermally limited accretion

occurs in the bow area, transitioning to maximum, and

mass limited, accretion zones at higher levels and far-

ther aft. The freezing fraction, as defined by the por-

tion of impinging spray water that remains trapped in

ice on the superstructure, also increases with distance

aft of the bow and with height above the water (Fig. 1).

The size and design of a ship also have other effects

upon the rate of superstructure spraying during icing

conditions, and the subsequent growth of topside ice.

Smaller vessels are immersed with spray more fre-

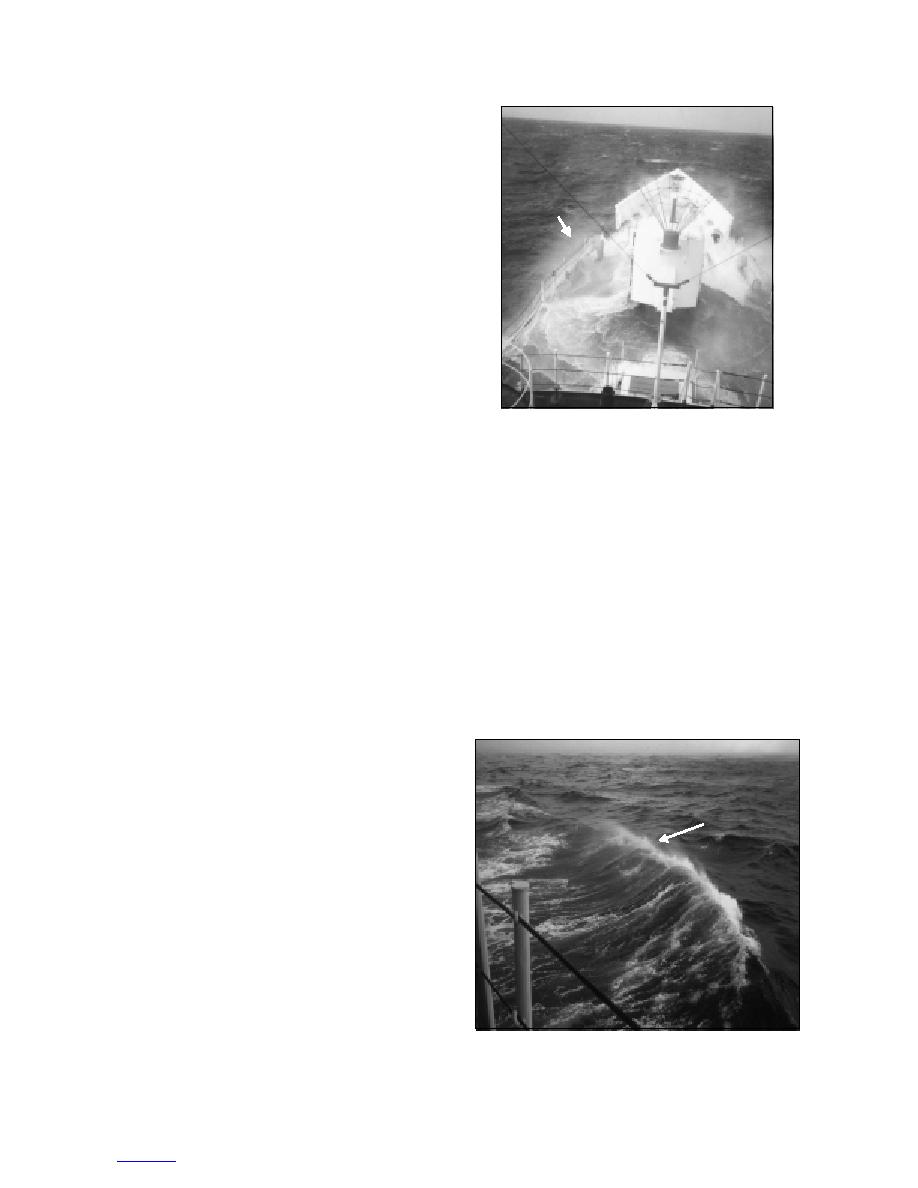

Figure 3. Deck spray created from water

quently than larger ships because of their lower free-

escaping over deck edge and through

board and greater heave frequency. Also, bow spray

scuppers. This is a secondary source

clouds are more likely to cover the entire superstruc-

of spray causing superstructure icing.

ture of a small ship with a large spray flux. Larger ves-

sels create spray less frequently because of their smaller

heave frequency and rate, and larger freeboard. In ad-

dition, bow spray clouds are less likely to cover all of a

measurements of superstructure spray and ice aboard

large vessel. Therefore, only a portion of the entire ship

the United States Coast Guard cutter Midgett in the

is likely to ice heavily, resulting in less rapid overall

Bering Sea during February and March 1990. The

accretion rates and less threatening accretions. Finally,

USCGC Midgett (Fig. 5) is not as large as a typical

the shape of the vessel's hull determines the amount of

Navy destroyer or cruiser at 378 ft (115 m) and 2980

spray lofted over the superstructure. Ships with greater

tons (2703 tonnes) displacement, but our measurements

freeboard in the bow area and greater bow rake or flare

were intended to characterize spray and ice conditions

will tend to deflect spray away from themselves, and

that might occur on a U.S. Navy ship. The size and sea-

reduce entrainment of drops into the relative wind

keeping ability of the cutter were certainly more repre-

(Sapone 1990).

Though bow spray generates the most liquid water

content, secondary spray also results when water accu-

mulated on decks drains over the edge or through scup-

pers. It also results from spume fountains. In the former

situation, wind moving up the side of the flared bow

Spume

entrains water draining from the decks, creating a sec-

fountains

ondary spray event that follows the primary event by a

few seconds. This secondary spray event prolongs to-

tal spraying but has small liquid water content (Fig. 3).

Light spray also originates along the windward sides

of ships in moderate or larger seas from interaction of

the bow wave with natural waves, causing breakers and

"spume fountains" (Fig. 4). Spume occurs only where

the bow wave and natural waves meet, causing them to

break, which happens at an increasing distance from

the ship with distance aft of the bow, creating a light

mist along the sides of the ship.

Figure 4. Spume fountains on the port side of

Research cruise

USCGC Midgett, a secondary source of spray.

CRREL was contracted by the U.S. Navy to make

3

to contents

Previous Page

Previous Page