100

80

60

54

44

39

38

40

28

26

22

21

18

20

8

2

0

0

Round

Subangular

Subround

Angular

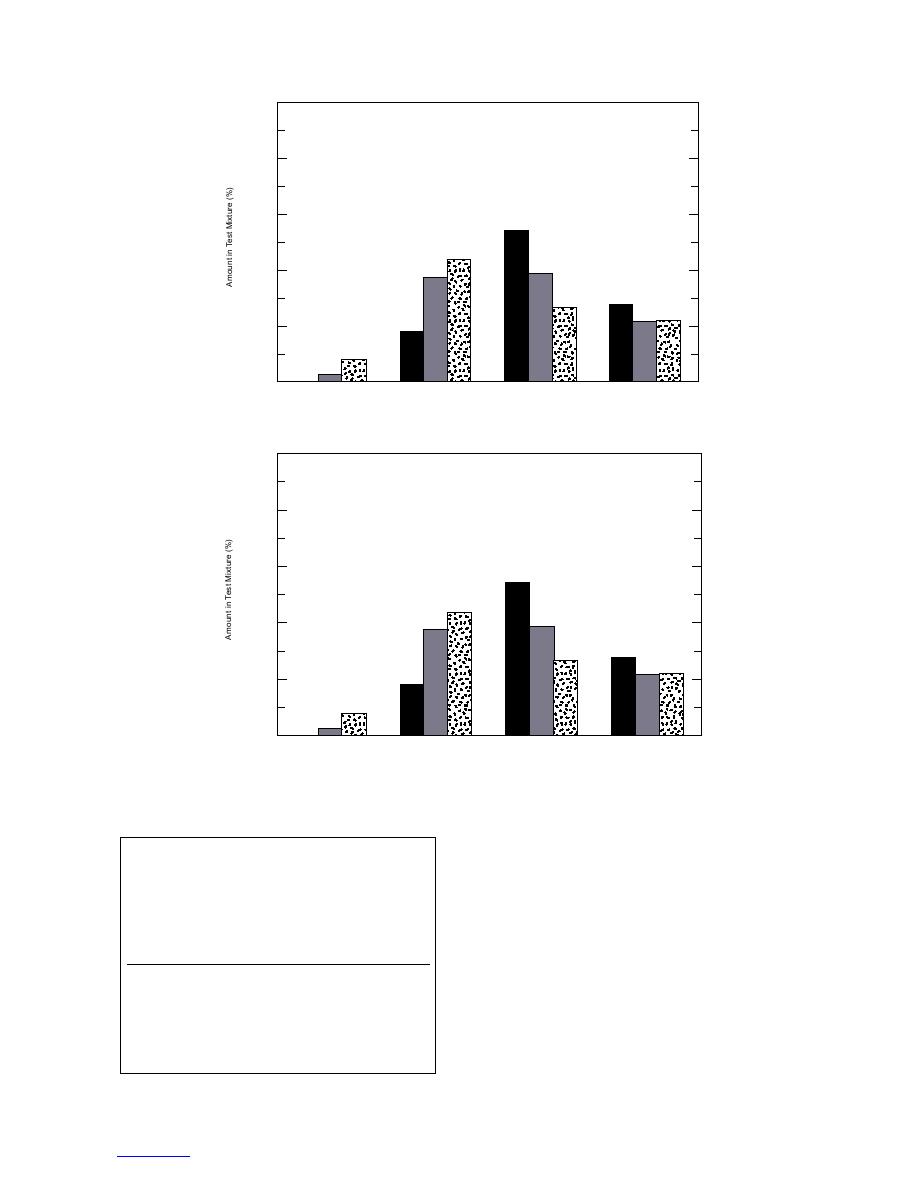

Figure 29. Examples of angularities in test aggregate.

100

80

60

54

44

39

38

40

28

26

22

21

18

20

8

2

0

0

Round

Subangular

Subround

Angular

Figure 30. Percentage of round, subround, angular, and subangular aggre-

gates in particle index test specimen.

this analysis, the bulk stress near the top of the base

Table 15. Average PI values for coarse and fine

course was around 400 kPa and was around 200 kPa in

aggregates as a function of percent crushed

the middle of the base course. We also chose these val-

aggregates.

ues because, as we saw from the results of the labora-

tory tests, the resilient modulus of the 100% natural

Voids in

Voids in

coarse

fine

material was actually higher than the 100% crushed

%

aggregates

Coarse

aggregates

Fine

material at stress levels of 200 kPa and less.

crushed

(%)

PI

(%)

PI

The resilient modulus values plotted in Figure 32

100

39.28

8.62

41.45

10.92

were taken at a void ratio of around 0.16. The results

80

39.07

8.41

show that it may be possible to use the PI as an indica-

75

38.46

7.81

40.30

8.99

tor of resilient modulus at a bulk stress of 400 kPa. At

60

37.93

7.29

200 kPa, the effect of PI on the resilient modulus was

50

36.27

5.65

41.72

11.02

25

35.39

4.80

39.66

9.62

negligible.

0

33.49

2.92

41.62

10.91

A similar attempt was made with the shear property

22

Previous Page

Previous Page