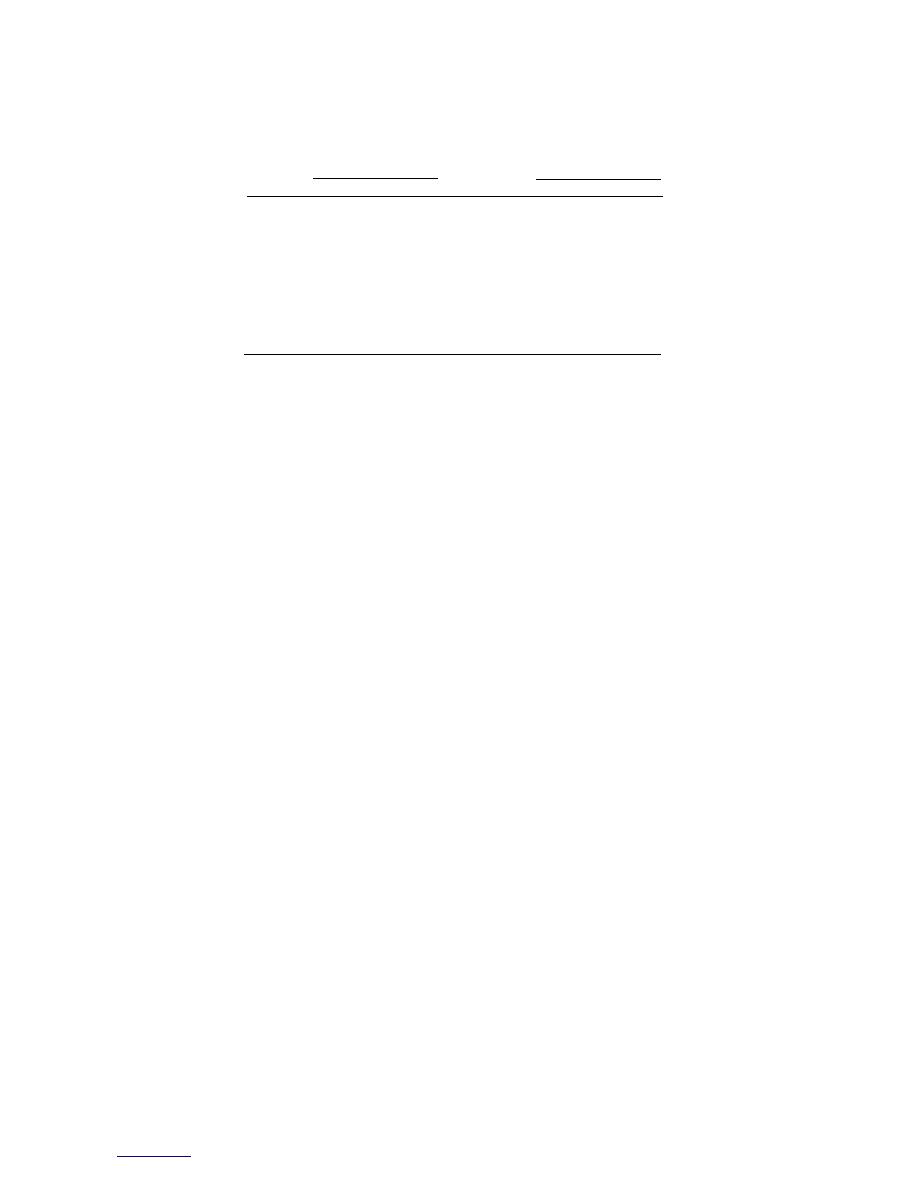

Table 5. Retention times for explosives-related compounds

by gas chromatography.

Retention time

Retention time

(min)

(min)

Analyte

DB-1 column RTX-200

Analyte

DB-1 column RTX-200

2,4,6-TNT

7.01

11.37

1,4-DNB

3.97

7.76

2,3,6-TNT

7.13

11.37

1,3-DNB

4.23

8.16

2,3,5-TNT

7.54

12.17

1,2-DNB

4.41

8.71

2,4,5-TNT

7.78

12.53

2,6-DNT

4.44

7.83

2,3,4-TNT

7.98

12.93

2,5-DNT

4.89

8.43

RDX

8.07

13.38

2,3-DNT

5.18

9.22

3,4,5-TNT

8.62

13.87

2,4-DNT

5.28

9.05

4-ADNT

9.14

12.54

3,5-DNT

5.50

9.46

3,5-DNA

9.24

13.00

3,4-DNT

5.79

10.25

2-ADNT

9.59

13.38

1,3,5-TNB

6.61

11.52

* The capillary column was a DB-1, 6 m 0.53 mm i.d., 1.5 m. Operating para-

meters were: initial column temperature of 100C (hold 2 min), ramp to 200C

at 10C/min, then 20C/min to 250C and hold for 5 min. The injection port

and detector temperatures were 250C and 300C, respectively. The carrier gas

was hydrogen with a constant flow rate of 12 mL/min. Analyte identities were

confirmed by analyzing a number of SPME samples on an RTX-200 capillary

column, 6 m 0.53 mm i.d. using hydrogen carrier at 10 mL/min.

Analyte identities were confirmed by analyz-

event, the fiber was thermally desorbed in the

injection port of the gas chromatograph (250C)

ing a number of SPME samples on an RTX-200

capillary column, 6 m 0.53 mm i.d.; the carrier

to assure that it was clean. To sample the head-

gas was hydrogen at 10 mL/min (Table 5). It

space, the aluminum foil was punctured by the

should be noted that whenever SPME fibers con-

needle housing of the fiber and the fiber was

taining TNT were desorbed into the hydrogen

extended into the headspace for a sorption period

carrier gas and separated on either the DB-1 or

of 20 minutes. The opening in the screw cap was

the RTX-200 columns, we observed peaks ascrib-

just the size of the outer diameter of the SPME

able to 2ADNT and 4ADNT (2-amino-4,6-dinitro-

holder and helped hold the assembly during

toluene and 4-amino-2,6-dinitrotoluene). Subse-

sampling. Later in the study, this sampling time

quent research revealed that these transformation

was reduced because the concentration of some

products of TNT were being produced by reduc-

analytes in the headspace increased to the point

tion of TNT by the hydrogen carrier, presumably

where the amount collected over the 20-minute

because of catalysis on the hot metal protective

sampling period maximized the detector signal.

needle of the SPME device. These amino reduc-

After the sampling was complete, the fiber was

tion products were eliminated when the carrier

withdrawn into its protective needle and the

gas was changed to helium.

needle was removed from the vial. The outside of

the needle was wiped with a tissue wetted with

acetonitrile to eliminate any vapors sorbed to the

RESULTS AND DISCUSSION

metal and inserted into the injection port of the

gas chromatograph. The GC-system consisted of

Qualitative nature of headspace signatures

The signature chemicals observed in the head-

an HP 6890 gas chromatograph equipped with a

micro-electron capture detector (ECD). The cap-

space samples above military-grade TNT were:

illary column was a DB-1, 6 m 0.53 mm i.d., 1.5

1,2- and 1,3-dinitrobenzene (DNB), 1,3,5-trini-

m. Operating parameters were: initial column

trobenzene (TNB), the various isomers of dinitro-

temperature of 100C (hold 2 minutes), ramp to

toluene (DNT), and 2,3,6- and 2,4,6-trinitrotolu-

200C at 10C/min, then 20C/min to 250C and

ene (TNT). 2ADNT and 4ADNT were also

observed, but, as mentioned above, we subse-

hold for 5 minutes. The injection port and detec-

tor temperatures were 250 and 300C, respectively.

quently determined that these two compounds

were being formed by reduction of 2,4,6-TNT in

The carrier gas was hydrogen with a constant

the presence of the hydrogen carrier gas in the

flow rate of 12 mL/min. Retention times for the

injector of the gas chromatograph (GC). We did

target analytes are presented in Table 5.

5

To Contents

Previous Page

Previous Page