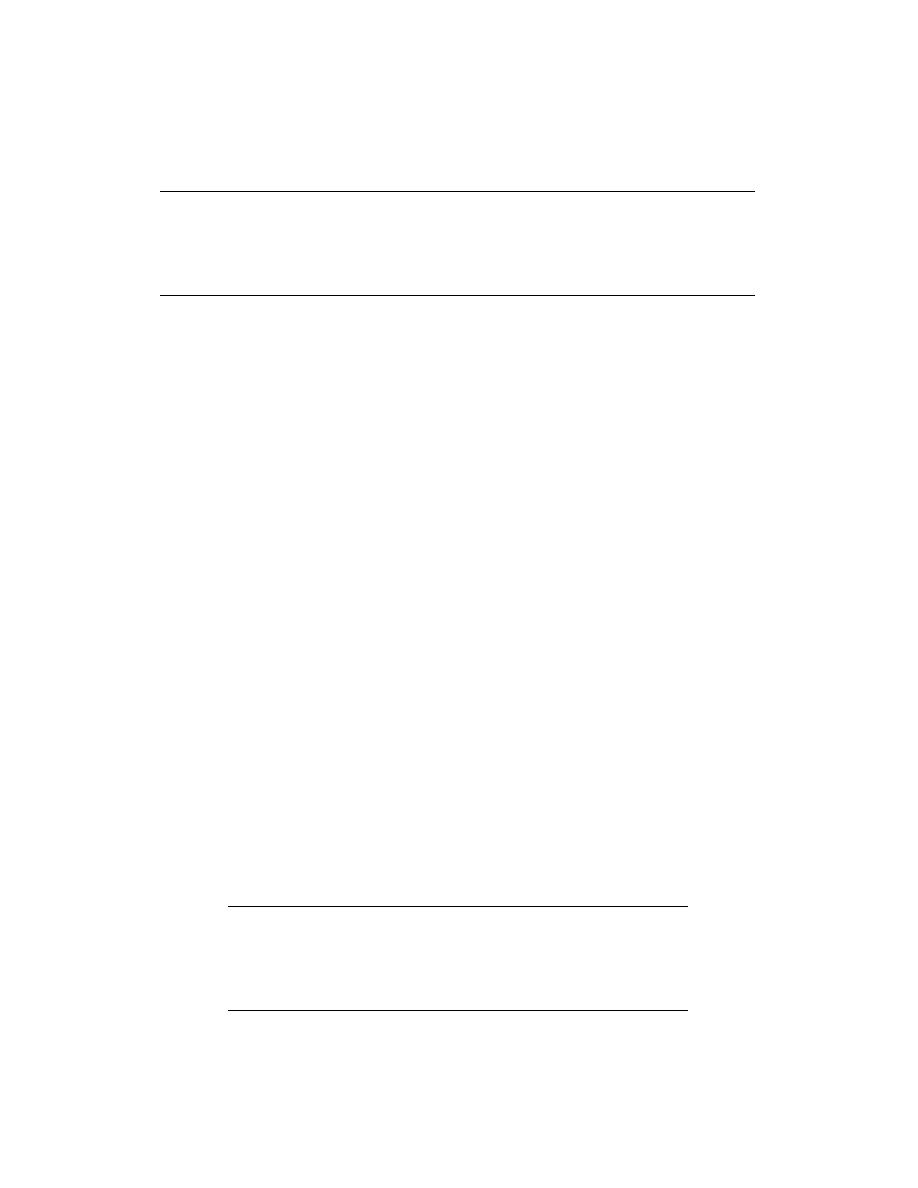

Table 6. Modified cup method.

Dry cup

Wet cup

Wt. change

Permeance

Membrane

weight gain

weight loss

per hour*

WVT

(perm) or

(gr/hr ft2)

(gr/hr ft2 in. Hg)

manufacturer

(gr)

(gr)

(gr/hour)

NEI

2.099

0.0037

0.038

0.034

1.898

Polyguard

2.269

0.0033

0.034

0.030

1.651

Protecto Wrap

2.222

0.0029

0.029

0.026

1.451

Royston

3.272

0.0058

0.059

0.052

2.948

Soprema

1.173

0.0014

0.014

0.012

0.741

W.R. Grace

3.117

1.589

0.0031

0.031

0.027

*Using the smaller of the weight gain of the desiccant or the weight loss of the water per hour by the slope

method as described in ASTM E 96.

Test temperature was 84F for an average vapor pressure difference of 1.1316 in. of Hg.

The sample area in all cases was 0.0985 ft2 and the length of the test was 560 hours.

of the water cup (linear regression slope of the lines

concluded our testing. Permeance values from

in App. F). WVT and permeance were calculated

these reports are italicized in Table 8 just below the

as discussed above. All weight changes in Tables

original published values. We consider the ex-

6 and 7 are corrected for changes in barometric

tremely low permeance report value for the NEI

pressure and due to measurement procedures in

membrane to be suspect. Our water-cup test per-

the case of Table 6.

meance values are also lower than those reported

The results of both these tests show that the

by all six manufacturers (considering their report

membranes have a permeance of about 0.01 to 0.05

data and ignoring the suspect NEI value). All six

perm. The results of these tests show that the per-

membranes are certainly water vapor resistant.

meance of all six tested membranes is nearly the

Three membranes were retested using the wa-

same. The average permeance for the modified-

ter-cup method after they were punctured with a

cup procedure is 0.030 perm, and the average

heated 0.06-in.-diam. steel rod. The permeance of

value for the water method is 0.028 perm. Both

the least permeable membrane (Soprema) in-

tests were run at an average temperature of 84F.

creased by an order of magnitude when we added

Table 8 compares both of our permeance test

the hole. The permeance of the next more perme-

results to the manufacturers' data. Note that test

able membrane (NEI) increased by a factor of 7

results from our water-cup method are lower than

when we added the hole. And the permeance of

those of our modified-cup method in all cases. We

the most permeable membrane (Royston) in-

attribute the decrease to problems experienced in

creased by a factor of 1.3 when we added the hole.

adequately tightening the modified-cup to avoid

These tests are difficult to conduct, and errors

leakage through the seals. Four manufacturers

may be introduced during sample preparation,

provided permeance test reports just before we

sample handling, and when obtaining weights and

Table 7. Wet-cup or water method with the following test conditions.

Total

Weight loss

Permeance

Membrane

weight loss

per hour

WVT

(perm) or

(gr/hr ft2)

(gr/hr ft2 in. Hg)

manufacturer

(gr)

(gr/hr)

NEI

1.914

0.0025

0.025

0.025

Polyguard

2.022

0.0026

0.026

0.026

ProtectoWrap

1.790

0.0021

0.021

0.021

Royston

3.596

0.0048

0.049

0.050

Soprema

0.849

0.0011

0.011

0.011

W.R. Grace

2.330

0.0031

0.031

0.032

*Using the slope method as described in ASTM E 96.

Test conditions were 84F and 16% RH for an average vapor pressure difference of

0.9824 in. of Hg.

The sample area in all cases was 0.0985 ft2 and the length of the test was 720 hours.

19

Previous Page

Previous Page