materials through which the passage of water va-

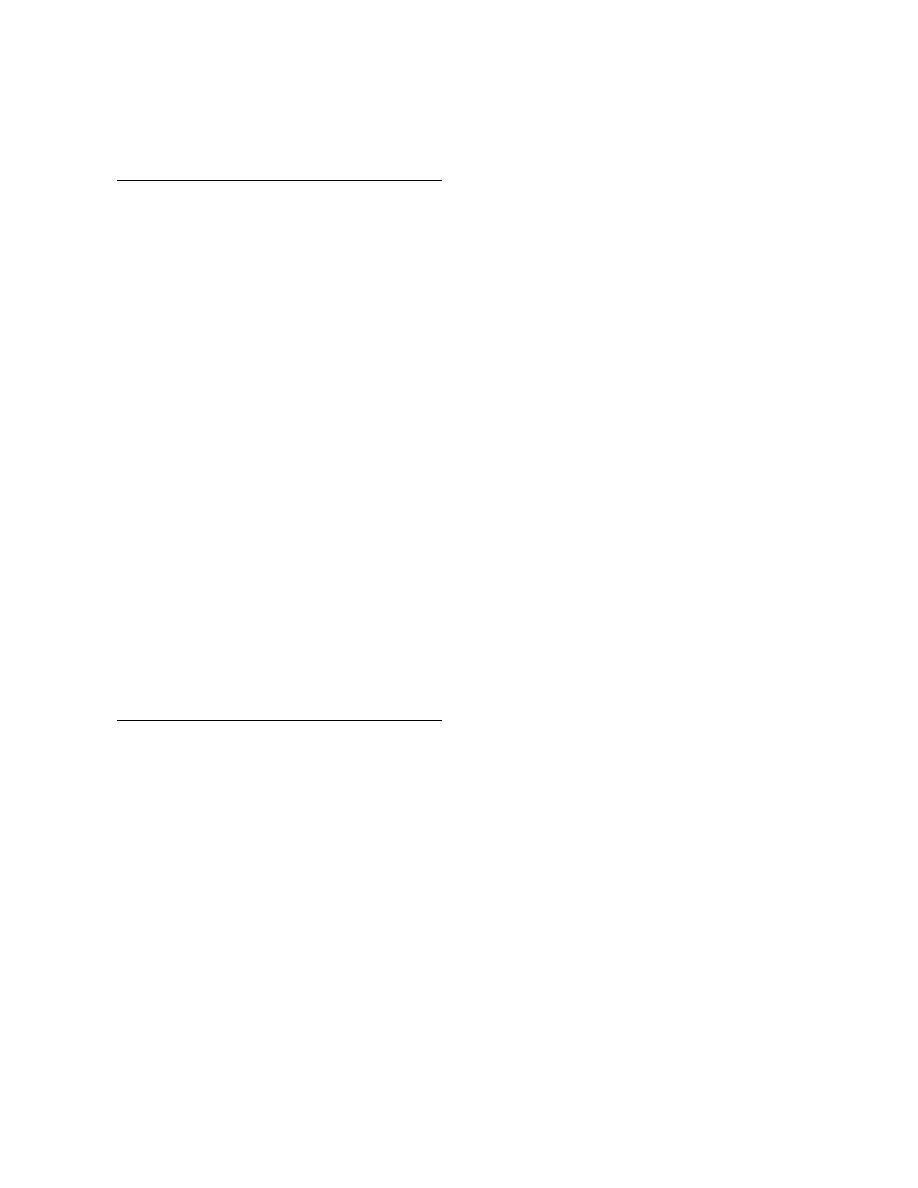

Table 4. Statistical analysis of puncture test re-

por may be of importance. There are two basic

sults.

methods, the Desiccant Method and the Water

Standard

Coefficient

Manufacturer

Average

deviation

of variation

Method. These methods are provided for the mea-

surement of permeance, and two variations in-

First set of 20 tests

clude service conditions with one side wetted and

Soprema

157.7

13.6

8.6

service conditions with low humidity on one side

NEI

88.4

9.3

10.5

and high humidity on the other. Some suggested

Polyguard

71.6

10.6

14.8

Royston

50.3

4.0

7.9

standard test conditions from E96 are listed be-

Protecto Wrap

38.5

4.1

10.7

low:

W.R. Grace

36.5

6.7

18.3

Procedure A Desiccant Method at 73.4F

Column average

73.8

8.0

11.8

(23C)

Procedure B Water Method at 73.4F (23C)

Second set of 20 tests

Soprema

148.5

12.3

8.3

Procedure BW Inverted Water Method at

NEI

99.5

16.3

16.4

73.4F (23C)

Polyguard

53.8

7.0

13.0

Procedure C Desiccant Method at 90F

Royston

51.7

10.0

19.3

(32.2C)

Protecto Wrap

39.7

3.4

8.6

Procedure D Water Method at 90F (32.2C)

W.R. Grace

36.0

6.3

17.5

Procedure E Desiccant Method at 100F

Column average

71.5

9.2

13.8

(37.8C) and a 90% RH

Third set of 20 tests

Soprema

142.6

16.1

11.3

Procedures A through D are normally con-

NEI

90.9

10.4

11.4

ducted in a test chamber at 50% relative humidity.

Polyguard

70.0

12.5

17.8

Agreement should not be expected between results

Royston

42.1

4.4

10.5

obtained by different methods and that method

Protecto Wrap

37.5

7.1

19.0

should be selected which more nearly approaches

W.R. Grace

39.0

8.1

20.7

Column average

70.3

9.8

15.1

the conditions of use.

A "perm" is the inch-pound unit of measure-

Fourth set of 20 tests

ment for permeance. One "perm" is the mass rate

Soprema

149.6

14.0

9.4

of water vapor flow through one square foot of

NEI

92.9

12.0

12.9

material or construction of one grain (gr) per hour

Polyguard

65.1

10.0

15.4

Royston

48.0

6.1

12.7

induced by a vapor pressure gradient between two

Protecto Wrap

38.5

4.9

12.6

surfaces of one inch of mercury or in units that

W.R. Grace

37.2

7.0

18.9

equal that flow rate (JTI 1990):

Column average

71.9

9.0

13.7

1 perm = 1 gr/h ft2 in. Hg =

5.75 1011 kg/s m2 Pa.

Historically, a material or system with a per-

among the bottom three membranes, because the

meance of 1 perm or less qualifies as a vapor re-

magnitudes of their data scattering exceed the dif-

tarder. More recently, further classification of va-

ferences in their puncture resistance.

por retarders has been proposed. For example, the

Canadian General Standards Board (CGSB) has

WATER VAPOR PERMEANCE

specified Type I vapor retarders as ones with a

permeance of 0.25 perm or less, and Type II as re-

This study reviewed and evaluated the suitabil-

tarders with a permeance of 0.75 perm or less be-

ity of the ASTM E96-95 Standard Test Methods for

fore aging and 1 perm or less after aging (ASHRAE

Water Vapor Transmission of Materials to sheet mem-

1997).

branes used as waterproofing between concrete

Table 5 summarizes the membrane manufac-

bridge decks and asphalt overlays used as the traf-

turers' data for the six membranes tested. The data

ficking surface. A modified test method, which is

are sorted from lowest to highest permeance and

under consideration for inclusion in ASTM E96,

shows that these values range from 0.003 to 1 perm

was investigated and the results compared to a

and vary by a factor of 333. The membrane thick-

variation of one of the standard test methods.

ness varies from 60 to 170 mils. The manufactur-

The test methods in ASTM E96 cover the deter-

ers generally tested their membranes using E96

mination of water vapor transmission (WVT) of

15

Previous Page

Previous Page