Table 12. Core sample findings for roof D7.

Moisture

content

Thickness

(% of

TRR

Core

Insulation

(in.)

dry weight)

(%)

Status

11

EPS

6

2

100

dry

11

EPS

6

508

65

WET

11

PER (frozen)

1

116

54

WET

Notes:

The upper layer of EPS was damp on its bottom.

The lower layer of EPS was mostly frozen.

The thermal image of the entire roof, being of a

inches of hydrostatic pressure in the vertical seams

uniform tone, suggests that the lower layer of EPS

between the 13-in.- (33-cm-) high "pile" of insula-

insulation is wet over the entire roof. If this is true,

tion boards in this roof. That moisture froze at its

that is indeed unfortunate since this is a relatively

base, allowing the water above to spread laterally

new roof. Additional samples should be taken to

within the roof along the vertical seams and hori-

determine the full extent of wet insulation in this

zontal surfaces between boards. In the process, the

roof.

continuous downward vapor drive forced that

We were not able to determine the source of the

moisture into the perlite and EPS insulations

moisture found in this roof. Thermographically,

The samples taken on this roof were near its

there were no brighter or darker areas of the type

perimeter. It is possible that air infiltration at in-

that point to the membrane and flashing flaws

adequate seals between the roof and walls allowed

through which moisture is currently gaining ac-

moisture into this area, or that the amount of wet

cess. Since vapor drive is downward year-round

insulation diminished gradually with increasing

for a freezer in Texas, we do not think this is a

distance from the perimeter. These possibilities

condensation problem. We speculate that enough

further support the need for additional samples.

moisture has entered at membrane or flashing

It takes quite some time to dry out most wet

flaws on occasion in the past to create several

insulations, particularly cellular plastic insulations

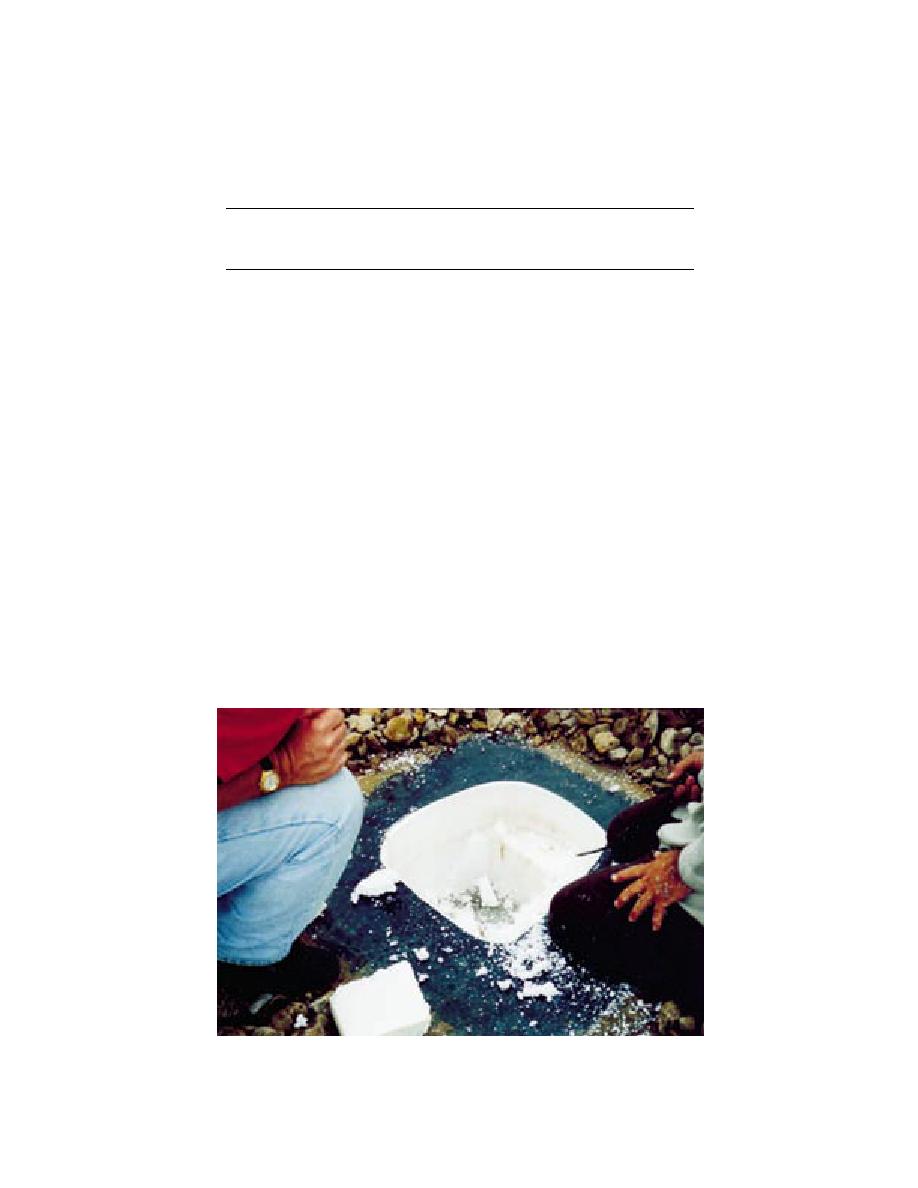

Figure 25. Taking cut F on roof D7. The lower layer of EPS was "full" of ice and

frozen to the deck. A 12- 12-in. sample of it could not be obtained.

21

Previous Page

Previous Page