45

44

43

42

41

40

0.70

0.60

1.00

0.90

0.80

Rounded

Angular

Sphericity and Angularity

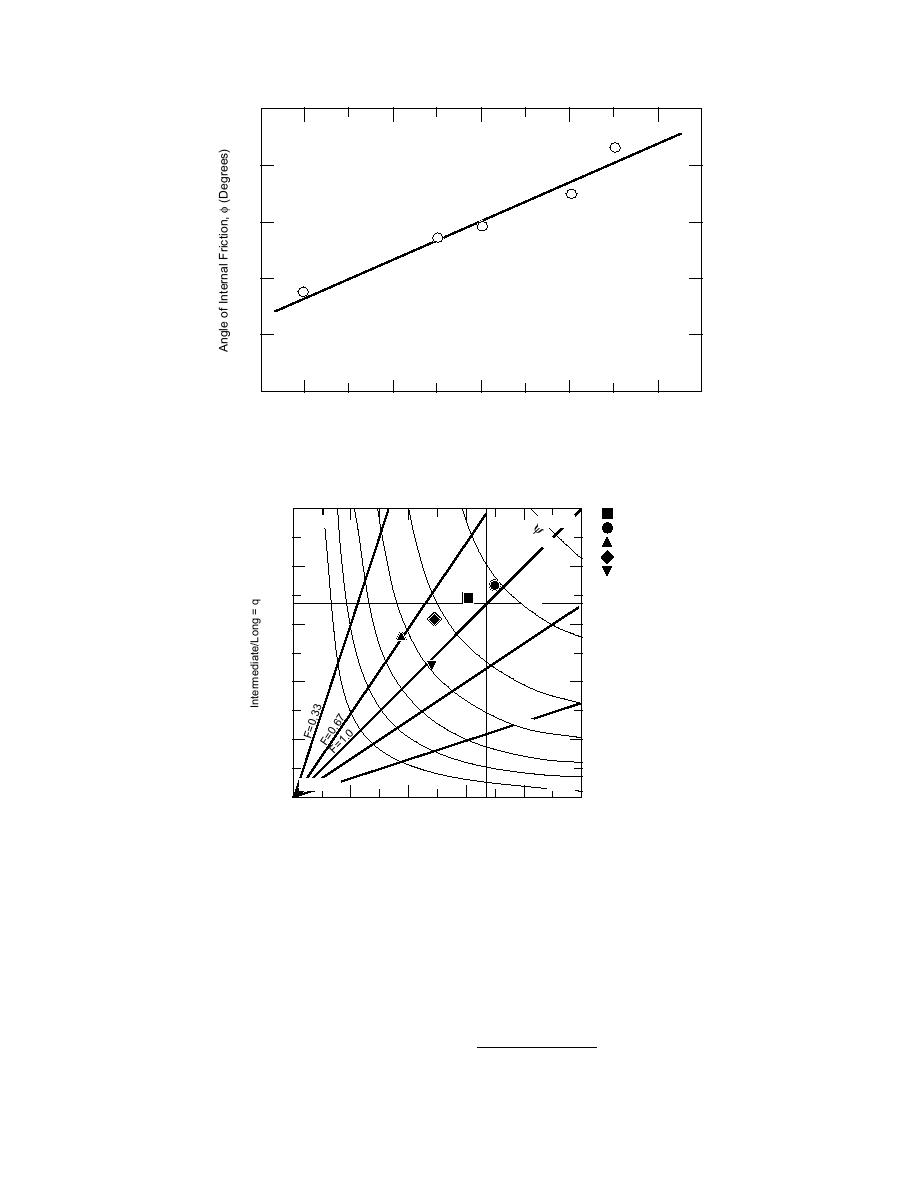

Figure 20. Effect of sphericity and angularity on the angle of internal friction.

(After Holubec and Wilson 1970.)

1.0

Granite

DISC

CUBIC

Gravel

=

0.

Shale

95

Quartzite

0.8

ψ

=

0.

9

0.6

ψ=

0.4

0.8

ψ=

0.7

ψ =0

0.2

5

.6

1.

ψ = 0.5

F=

.0

ψ = 0.4

F=3

BLADE

ROD

0.0

0.0

0.2

0.4

0.6

0.8

1.0

Short/Intermediate = p

Figure 21. Shape classification of aggregates. (After Barksdale and Itani 1994.)

The test materials, shape, and surface charac-

men diameter be at least six to seven times the

teristics as reported by Barksdale and Itani (1994)

maximum particle size, to minimize the bound-

are shown in Figure 21. The samples were com-

ary effects by the large aggregates. Scalping of

pacted using a vibratory compactor at the opti-

large aggregates and replacing equivalent

mum moisture content. The test specimens were

amounts of smaller aggregates changes the over-

152 mm in diameter and 305 mm in height. These

all structure of the material. Dawson* reported

dimensions are acceptable provided the maxi-

that in unreported experiments at the University

mum size of the aggregates is no more than 25

of Nottingham, similar results were obtained on

mm. Sweere (1990) found that testing aggregates

dry specimens in which the grading curve was

containing 51-mm particles in a 152-mm-diameter

mold produced inconsistent results. He recom-

* Personal communication, Andrew Dawson, University of

mended that, for large particle sizes, the speci-

Nottingham, United Kingdom, 1992.

18

Previous Page

Previous Page