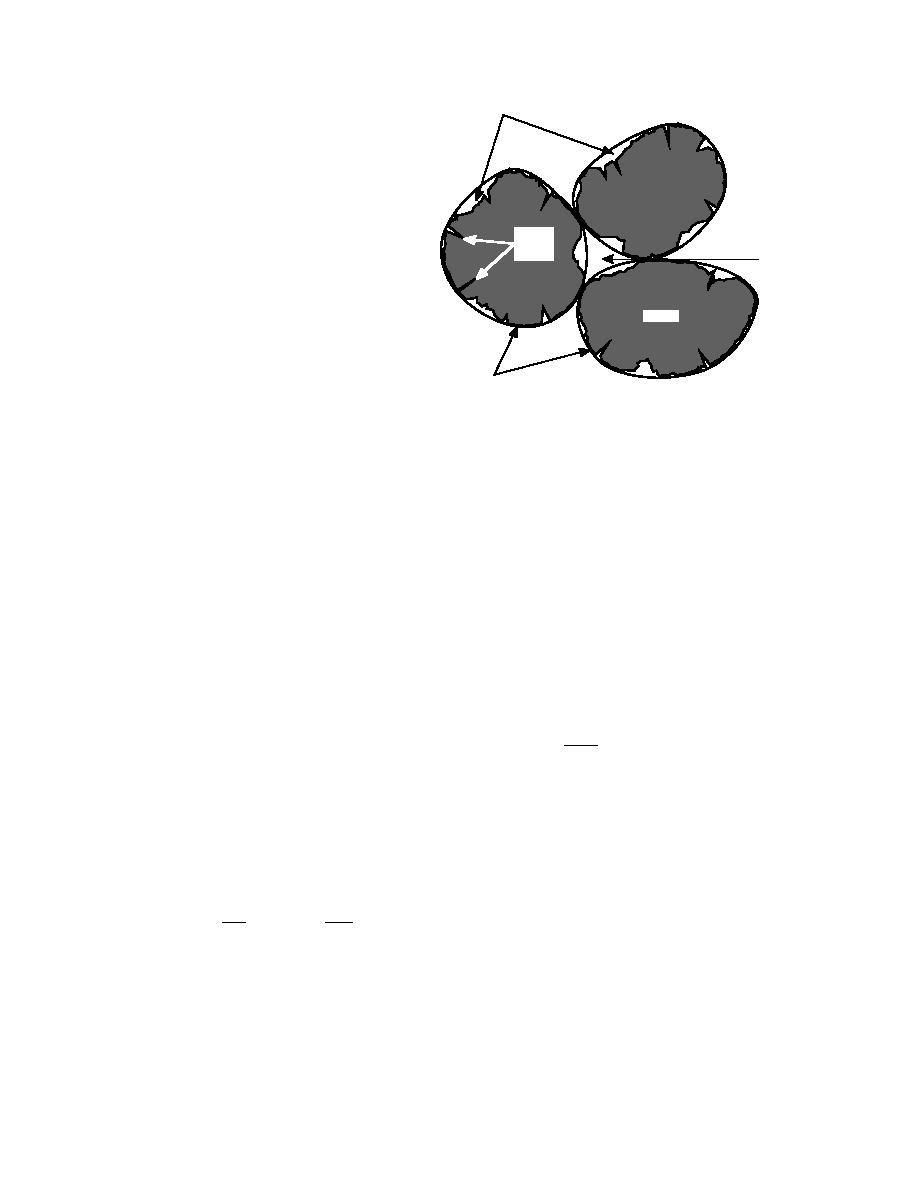

Macro-Surface Voids

Specific rugosity index

Tons and Goetz (1968) developed the

packing volume concept to characterize the

shape, angularity, and roughness of the ag-

gregates used in bituminous mixtures. The

test was developed for both the coarse (12.7-

mm max) and fine fractions. They decided

Micro-

that the shape of the particle could possibly

Surface

Packing

Voids

be quantified as a separate value; however,

Porosity

Voids

it was difficult to separate the interaction of

angularity and roughness on aggregate per-

formance. They proposed that the effect of

Solids

both angularity and roughness be combined

and considered in one term, "rugosity."

The assumption is that the volume of an

Packing Volume Membrane

individual particle in an aggregate mass de-

termines the density and voids in the bulk. Figure 13. Packing volume, packing porosity, and geometric

This volume, called the "packing volume," irregularity of aggregate particles. (After Ishai and Tons 1977.)

had to account for the volume of the solid

particle, the volume of internal voids, and the vol-

ume of "outside voids." The "outside voids" vol-

The apparent specific gravity of the aggregates

ume is made up of the volume of the dips and

can be calculated using ASTM Test for Specific

valleys on the aggregate surface (Fig. 13). The

Gravity and Absorption of Coarse Aggregate (C

packing volume can be imagined as a membrane

127). Gpx is determined from the pouring test

around the aggregate.

developed by Ishai and Tons (1977). The test in-

The packing volume membrane divides the

volves taking two one-sized particles and pour-

voids into two components, the interparticle voids

ing them into a standard container using a stan-

and particle surface voids (Ishai and Tons 1977)

dard procedure. One of the particles is used as a

(Fig. 13). For one-sized particles, it is assumed that

standard (smooth, spherical glass beads) with a

the interparticle voids are constant and this poros-

known packing specific gravity, Gps. The other is

ity is the same as that obtained from same one-

the test particle for which Gpx is sought. Gpx is a

sized smooth spherical particles. Tons and Goetz

function of the ratio of the weight of the test parti-

(1968) assumed that aggregate shape can be math-

cle to the standard particle:

ematically defined as ellipsoids. They found that

the porosity calculated from ellipsoids or spheres

ΣWx

Gpx =

Gps

of the same size had the same amount of voids.

ΣWs

Any difference, then, between the porosity of the

smooth spherical particles and the aggregates is

where Ws = weight of the standard

due to the irregularities of the aggregates.

Wx = weight of the test material

Ishai and Tons (1971) developed a specific rug-

Gps = packing specific gravity of standard

osity (Srv) index to express the total geometric ir-

material

regularity of the particle. Srv will be approximately

Gpx = packing specific gravity of test mate-

equal to zero for smooth, spherical particles:

rial.

Gpx

V

A schematic of the pouring test is given in Fig-

sr = 1001 -

Srv = 100

Gap

Vp

ure 14. The specifications for the pouring test ap-

paratus for the coarse aggregate fraction are giv-

en in Table 12.

where Srv = specific rugosity (%)

Some typical results as presented by Ishai and

Vsr = volume between the packing volume

Tons (1977) are shown in Figure 15. The specific

membrane and the volume of macro

rugosity of two sizes, 12.7 to 15.9 mm and #3 to

and micro surface voids

#4 sizes for natural gravel, crushed gravel, lime-

Vp = packing volume of the particle

stone, and beach pebbles are plotted. The specific

Gpx = packing specific gravity

rugosity increases as the material becomes more

Gap = apparent specific gravity.

13

Previous Page

Previous Page