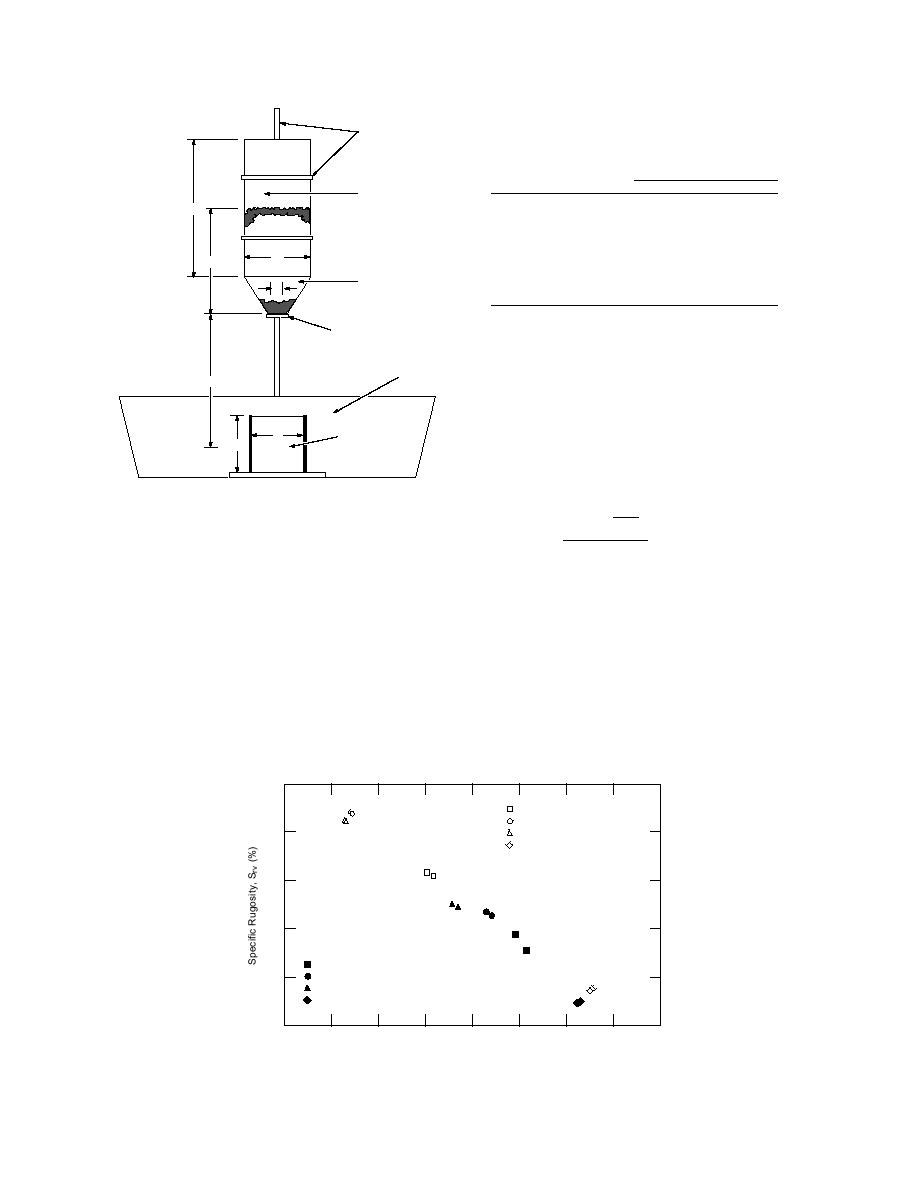

Table 12. Specific setups for coarse fractions

for the pouring test. (After Ishai and Tons

Supports

1977.)

Dimensions

Coarse fractions

(cm)

12.7 to 15.9 mm

#3 to #4

Bin

c

Bin diameter

16.0

16.0

Funnel orifice diameter

3.0

1.44

Aggregate head

12.0

12.0

Pouring height

21.0

21.0

D

b

Container diameter

12.2

10.3

Funnel

Container height

15.2

11.8

a

Bead diameter (avg.)

16.0

6.0

volves allowing the fine aggregates to freely fall

Bin Shutter

into a calibrated cylinder from a specified height.

Large Pan for

The exception here is that the aggregates are not

Particle Collection

H

separated into various sieve sizes, as is done with

the other index tests. The test for fine aggregates

is designated by ASTM as Test Method C 1252.

φ

The weight of aggregate and the bulk specific

Container

h

gravity are used to calculate the uncompacted

void content:

H = Pouring Height

D

=

Bin Diameter

M

φ = Container Diameter

a

=

Funnel Office Diameter

Vcyl -

h = Container Height

c

=

Bin Height

Gsb

b

=

Aggregate Head

UVC =

100

Vcyl

Figure 14. Schematic description of the pouring device.

(After Ishai and Tons 1977.)

where UCV = uncompacted void content (%)

Vcyl = volume of cylinder (cm3)

angular and rougher. Also shown in the figure is

M = mass of aggregate in cylinder (g)

the effect of aggregate size on the specific rugos-

Gsb = bulk specific gravity of aggregates.

ity. The value of the specific rugosity increases as

the size of the material decreases.

UCV increases with increasing angularity and

roughness of the aggregates. Aldrich (1996) mod-

Uncompacted voids in aggregates

ified this test for coarse aggregates. A schematic

This test method is similar to the specific rug-

of his test apparatus is shown in Figure 16. The

osity test. Initially developed for fine aggregates

coarse aggregate for the test passed the 19-mm

by the National Aggregate Association, it in-

sieve and was retained on the #4 sieve. The test

25

Natural Gravel (#3 to #4)

Crushed Gravel (#3 to #4)

20

Limestone (#3 to #4)

Beach Pebbles (#3 to #4)

15

10

Natural Gravel (1/2 to 3/8 in.)

Crushed Gravel (1/2 to 3/8 in.)

5

Limestone (1/2 to 3/8 in.)

Beach Pebbles (1/2 to 3/8 in.)

0

2.1

2.2

2.5

2.6

2

2.3

2.4

2.7

2.8

Packing Specific Gravity (Pouring), Gpx

Figure 15. Packing specific gravity and rugosity for different aggregates.

14

Previous Page

Previous Page