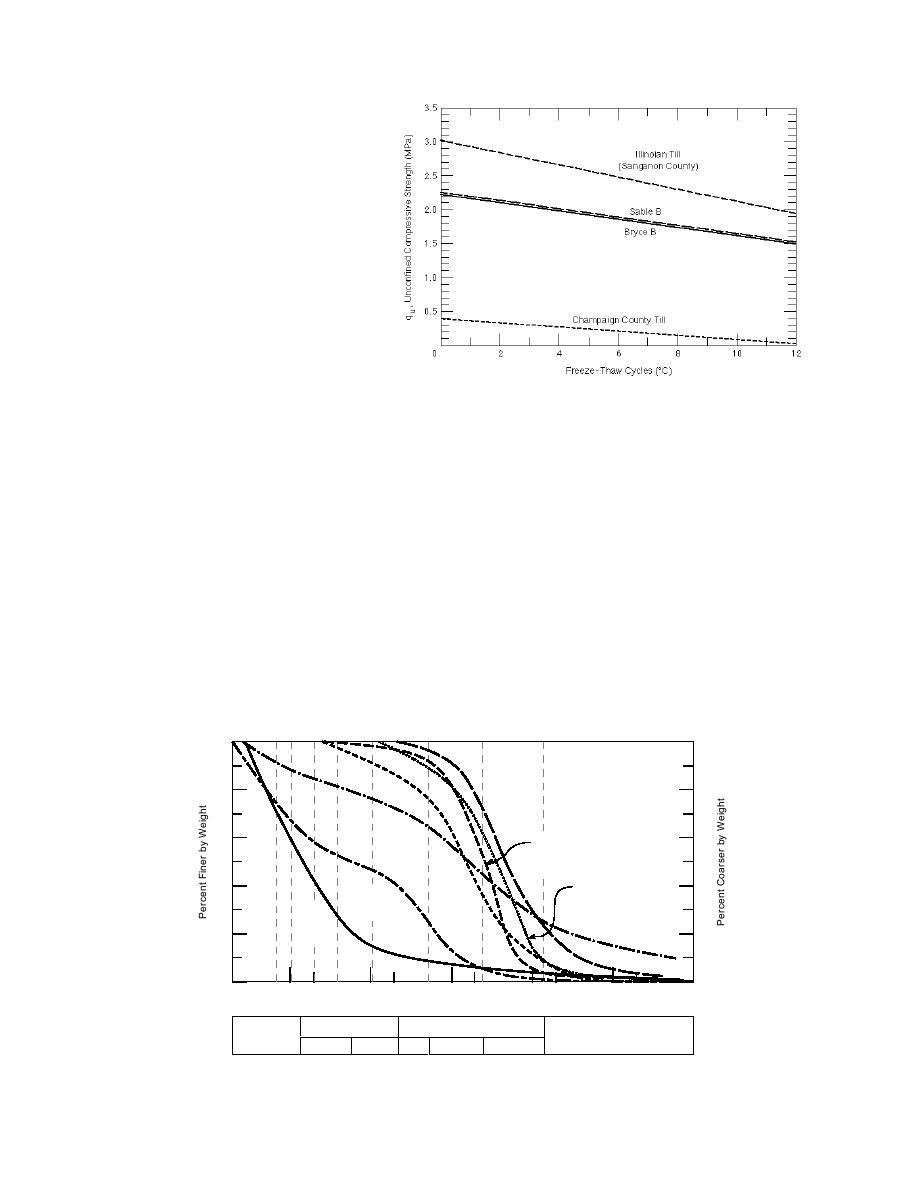

Figure 19. Influence of freezethaw cycles on

unconfined compressive strength of limesoil

mixtures (48-hour curing at 120F) (1 kip/in.2

= 6.89 MPa) (after Thompson 1969b).

cement (5, 10, 15%), compacted at the optimum

the material prior to freezing. The residual refers

to strength of the thawed specimens after the

moisture content and cured for 7 days. The CL-

ML and ML soils were compacted at 14% mois-

ASTM freezethaw test (D-560), i.e., after 12

ture content. The tests were conducted using

freezethaw cycles. The results indicate that the

Marshall-type cylindrical samples. Kettle and

strengths of most of the soils at 5% cement treat-

McCabe attempted to relate the results from the

ment are drastically reduced after 12 freezethaw

durability test (D-560, ASTM 1992c) to the resil-

cycles. At 15% cement level, most of the soils

ient modulus and tensile strength of the soil sub-

actually gained some strength.

jected to a number of freezethaw cycles. They

Brandl (1981) also reported results where low

found that the resilient modulus after three thaw

lime contents actually reduced the tensile

cycles was a good indicator of materials that

strength of the mixture. He attributed it to poor

failed the durability test.

cementing between the soil particles. The results

after freezethaw cycling (≤10% cement) indicate

A summary of the tensile strength and Mr is

either poor cementation or breaking of the soil

presented in Tables 16 and 17. The before-freeze

cement bonds. Poor cementation may not be the

data in Table 16 refer to the average strength of

U.S. Standard Sieve Numbers

Hydrometer

6" 4"

2"

1"

10

40

200

3/8"

100

0

80

20

Graves

Sand

60

40

Hart

Brothers

Sand

40

60

Ikalanian

Hyannis

Natural

Sand

Sand

Subgrade

Dense

Graded

Sibley

20

80

Stone

Till

100

0

100

10

1

0.1

0.01

0.001

Grain Size (mm)

Gravel

Sand

Cobbles

Silt or Clay

Coarse

Fine

C'rse

Medium

Fine

Figure 20. Grain size distributions of test soils and natural subgrade.

23

Previous Page

Previous Page