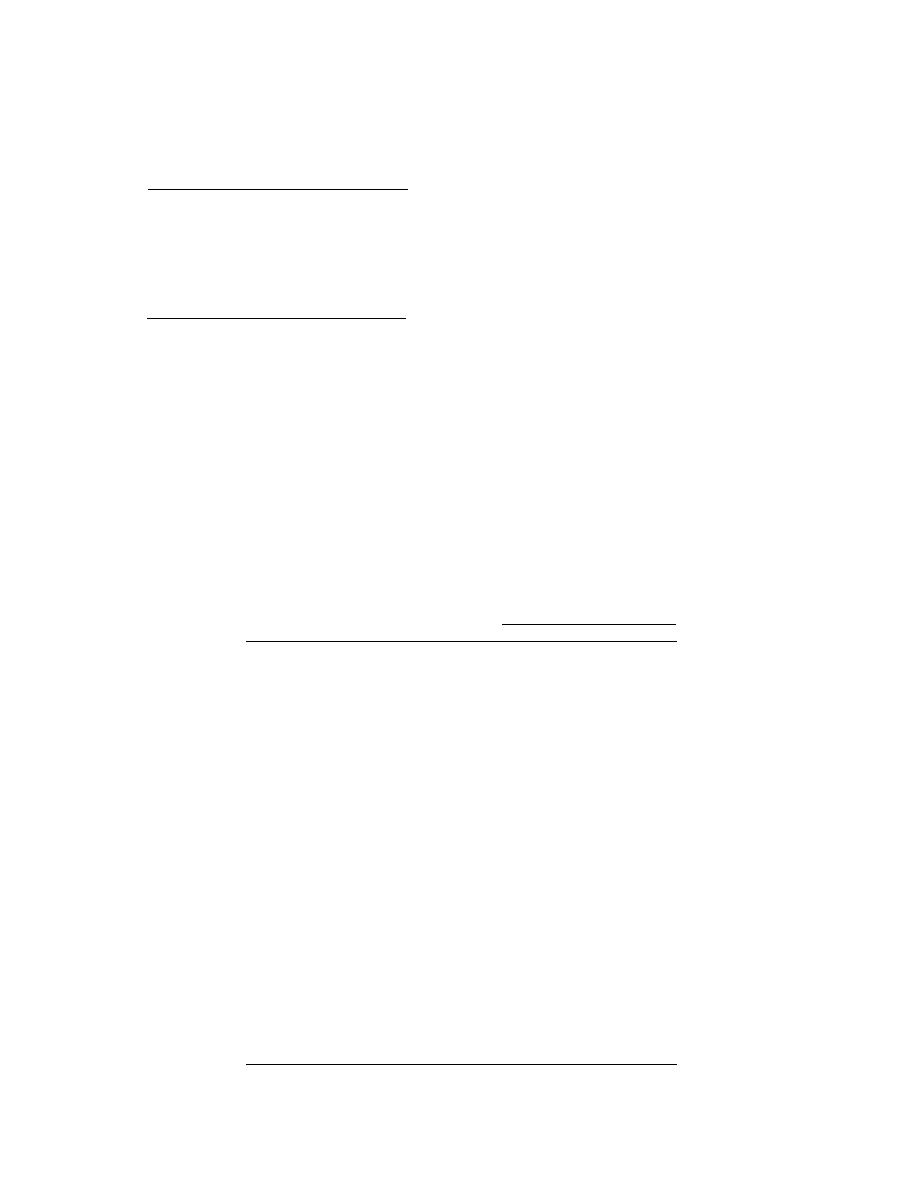

Table 13. Estimated k values used in

of days to drain to any drainage level. None of the

analysis.

FAA specified base or subbase materials meet the

COE criteria. However, for thicker bases (> 60

Percent

Material

passing

Permeability*

cm), this criterion could be met (or nearly met) if

type

no. 200 sieve

(cm/s)

the fines levels were below 3%. According to the

2.12 103

results of this analysis, P-213 is fairly imperme-

P-154, P-208, P-209

3

3.00 104

5

able, so this type of base material should not be

2.82 105

10

used in seasonal frost areas.

1.41 105

15

As one would expect, the drainability of the

8.82 105

P-213

3

base and subbase affects the resilient modulus

3.53 106

5

(Mr) of the layers. As the moisture content de-

1.76 107

10

3.00 108

creases, the resilient modulus of the material will

15

increase. Other factors that directly or indirectly

* 1 cm/s = 0.033 ft/s.

affect the resilient modulus are temperature,

uration level of 80%. As mentioned earlier, once

permeability, angularity, and percent fines in the

the degree of saturation is below 85%, base courses

mixture. Our limited data show that the change in

tend to become stable again. The COE criterion for

Mr of bases or subbases during thaw-weakening is

drainage layers is that 50% drainage should take

dramatic. A typical resilient modulustemperature

place within 10 days, thus the choice of 50%. The

relationship for base and subbase material is

99% level describes the base course as being com-

shown in Figure 17 (Cole et al. 1987). As the

pletely drained.

temperature increases (as during spring thaw),

The effect of fine content on the drainability of a

the resilient modulus of the subbase and base

61-cm-thick (24-in.-thick) base or subbase layer is

course materials at Albany County Airport, New

shown in Figure 16. Clearly, the results show that

York, changes by a factor of 100.

as the fines content increases so does the number

The pavement structure under taxiway A at

Table 14. Basesubbase drainage.

Percent

Material

passing

Thickness*

Number of days to drain

type

no. 200 sieve

(cm)

U = 20% U = 50% U = 99%

P-154, P-208, P-209

3

15

10

42

353

61

4

23

350

152

2

12

295

15

71

295

2,492

5

61

31

163

2,473

152

15

85

2,079

15

754

3,129

26,480

10

61

329

1,733

26,271

152

156

902

22,092

15

1,508

6,258

52,960

15

61

658

3,466

52,542

152

313

1,804

44,183

P-213

15

320

1,327

11,226

3

61

139

735

11,137

152

66

382

9,365

15

7,991

33,164

280,641

5

61

3,486

18,367

278,429

152

1,657

9,562

234,133

15

159,821

663,281

5,612,815

10

61

69,727

367,340

5,568,590

152

33,137

191,238

4,682,654

15

940,124

3,901,656

33,016,560

15

61

410,160

2,160,821

32,756,409

152

194,922

1,124,929

27,545,025

* 1 in. = 25.4 mm.

20

Previous Page

Previous Page