General discussion on sorption

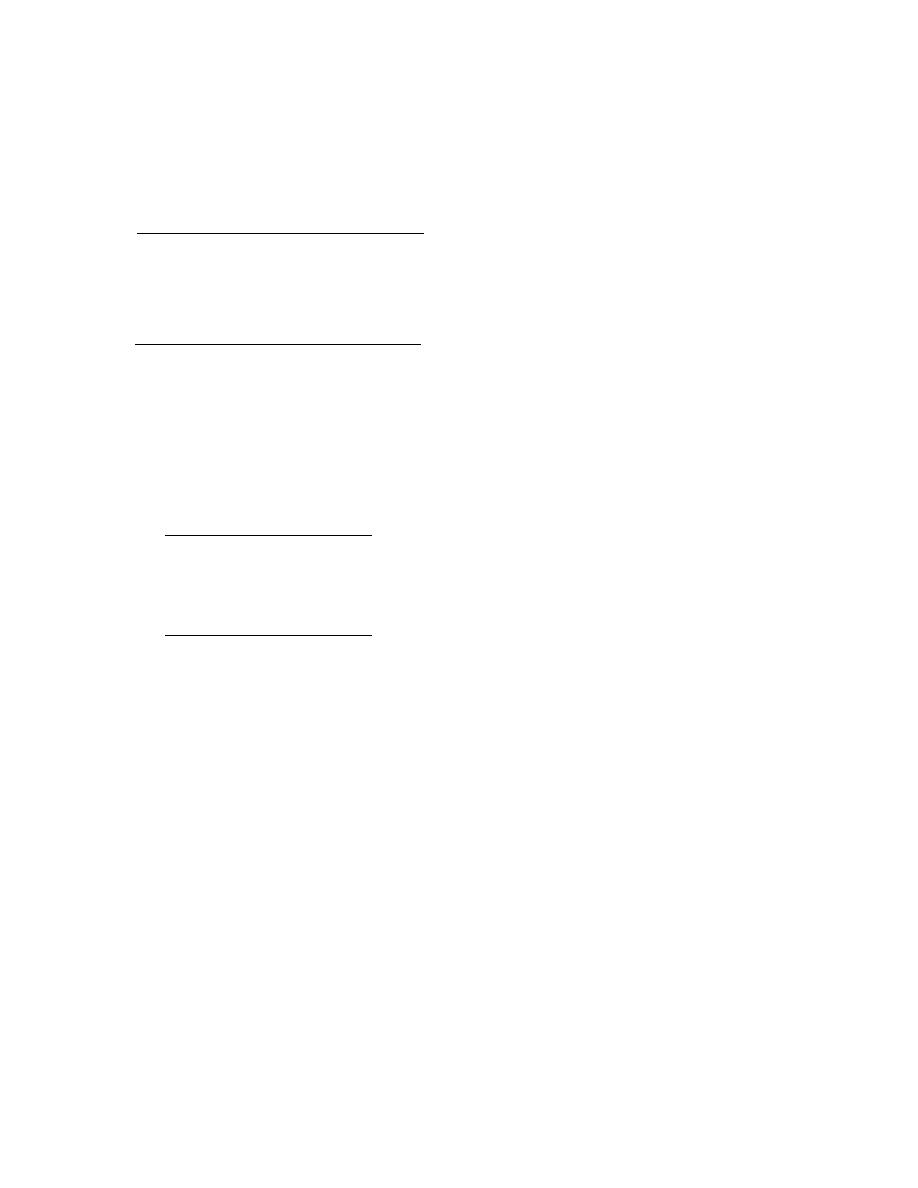

Table 5. Relationship between the pumping

time (t) and the relative concentration (Ct)

Our low-flow-rate studies indicate that al-

of TCE in water pumped through 100 ft of

though the more sorptive plasticized polypropy-

tubing at different flow rates.

lene tubings do reach equilibrium with the con-

taminated well water, the change in the normal-

Contact

Flow

time

(min)*

r†

(mL/min)

Relationship

enough to bias results. It appears that the less

sorptive LDPE could be used to sample TCE in all

LDPE

but the deepest wells (> 100 ft) if the tubing were

100

10

Ct = 0.785 + 0.0932 log(t)

0.954

equilibrated (pumped) for 24 hr. The question

1,000

1

Ct= 0.986 + 0.0082 log(t)

0.706

that then remains is what would happen with the

PP1

other analytes that are more readily sorbed by

100

10

Ct = 0.492 + 0.102 log(t)

0.909

1,000

1

Ct = 0.941 + 0.0205 log(t)

0.811

this tubing, such as PCE and PDCB (Parker and

Ranney 1996). Based upon our previous findings

* Time for water to pass through tubing.

(Parker and Ranney 1996), we expect that losses

† Correlation coefficient.

of PDCB and PCE would be substantially greater

Table 6. Predicted normalized

concentrations of TCE following

However, currently this is unproven.

pumping at 1 L/min for various

Clearly, the fluoropolymers tested in this

pumping times.

study [PVDF, P(VDF-HFP)] did not sorb much

TCE. We were surprised to find there was no sig-

Sample

nificant difference between the concentrations of

Tubing

contact

Pumping Predicted

length

time

time

normal

TCE in samples exposed to the PVDF and P(VDF-

(ft)

(min)*

(hr)

conc. TCE

HFP) tubings. In our previous study (Parker and

Ranney 1996), losses were always much greater

100

1

4

0.98

500

5

4

0.90

for test solutions exposed to the flexible fluo-

1,000

10

4

0.84

ropolymers than those exposed to the rigid fluo-

100

1

2

0.98

ropolymers. We suspect that we would have de-

500

5

2

0.88

tected some differences between these two mate-

1,000

10

2

0.81

rials if a longer length of tubing or a more sorp-

* Time for water to pass through tub-

tive analyte had been tested. However, this also

ing.

remains unproven.

ft of LDPE at 1 L/min (Table 5) and water

If the samples are to be pumped at a rapid rate

pumped through 10 ft of LDPE tubing at 100

(1 L/min), it appears that LDPE tubing can be

mL/min (Table 4). In both cases, the contact time

used to sample most wells for TCE, although 24

was 1 min. Thus, it appears that contact time can

hr should be allowed for equilibration in wells

be used to predict losses.

500 ft and greater. However, additional tests

We used the relationships derived in Table 4

should be conducted with longer lengths of tub-

for 5- and 10-min contact times to predict what

ing and more sorptive analytes to prove this.

the losses might be for TCE-contaminated water

pumped through 500 ft and 1,000 ft of LDPE at 1

Leaching findings

L/min, after allowing the tubing to equilibrate

We did not detect any spurious peaks, using

for either 2 or 4 hr. We see that if only 2 hr were

RP-HPLC analysis and a UV detector, in any of

allowed for equilibration, the estimated losses

the samples that had been pumped through any

would be only slightly greater than 10% for 500 ft

of the tubings used in these experiments, even

(Table 6). Only for the 1000-ft lengths would a

the longest lengths. However, we should men-

longer equilibration time (4 hr) be required if the

tion that because the concentration of our analyte

flow rate was 1 L/min. Thus, we would predict

of interest, TCE, was in the low mg/L range,

that longer lengths (500 ft and greater) of LDPE

these analyses were not highly sensitive. Also,

could be used to sample TCE at a flow rate of 1

UV detectors are not universal detectors and

L/min if 24 hr is given for equilibration. How-

many organic constituents that might be leached

ever, these predictions need to be verified by ad-

would not be found using this type of detector.

ditional testing, and other analytes need to be

UV detectors are most sensitive for conjugated

considered.

bonds and sulfur-, nitrogen-, bromine-, and iodine-

12

Previous Page

Previous Page