1.0

0.8

0.6

0.4

PVDF

PE

PP2

0.2

PP1

(VDF-HFP)

0

100

200

300

400

Time (h)

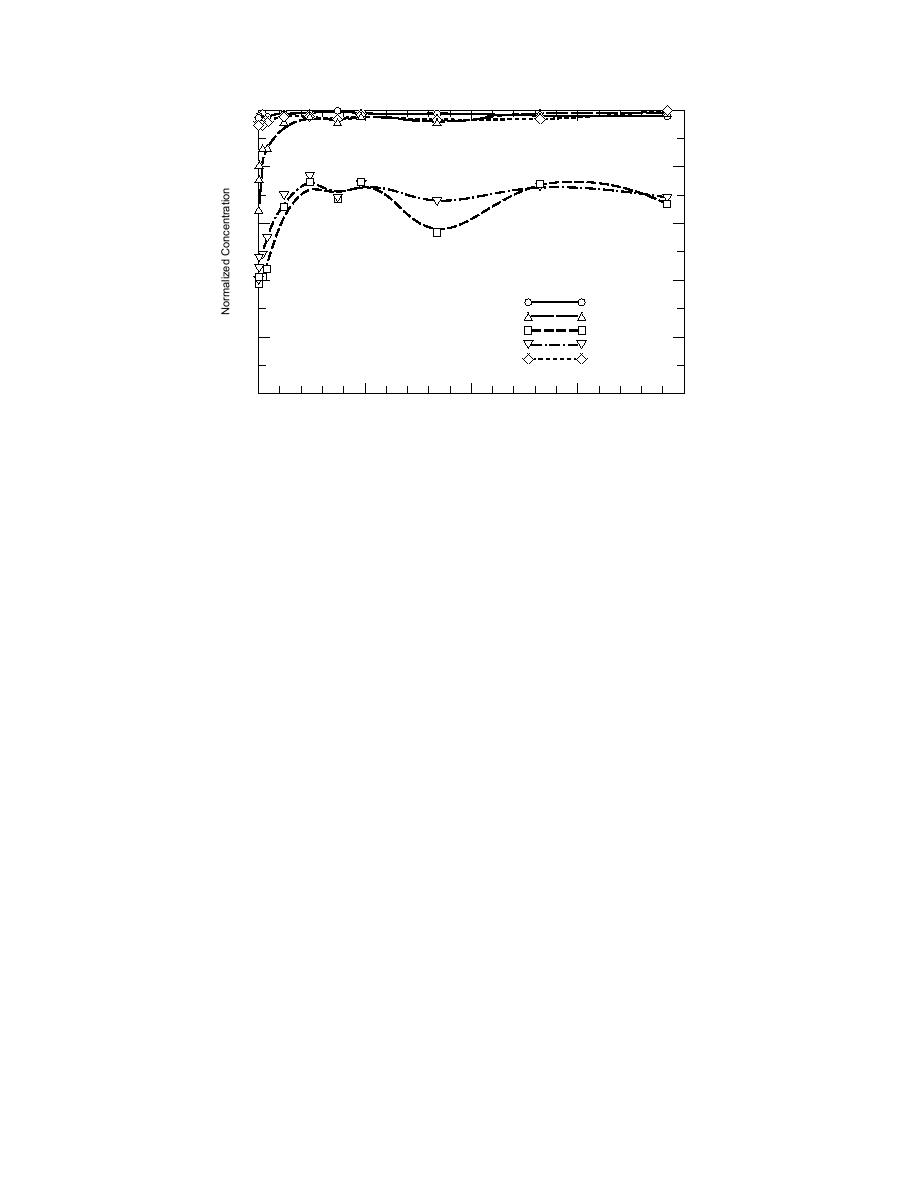

Figure 7. Normalized concentration of TCE in water pumped through 100 ft of

tubing at 100 mL/min.

centration of TCE in well water that was pumped

materials, both initially and at equilibrium. For

through 10-ft, 50-ft, and 100-ft lengths of PVDF,

example, after ten minutes' contact, ~60% of the

P(VDF-HFP), PP1, PP2, and LDPE tubings at a

TCE was sorbed by the 100-ft sections of these

flow rate of 100 mL/min. (Appendix Table A1

tubings. However, losses were still substantial at

gives the mean normalized concentrations, and

equilibrium with losses of 1020% for the 50-ft

Appendix Table B1 gives the actual concentra-

sections and 30% for the 100-ft sections. We are

tions of TCE [in mg/L] in the well water before

not certain what accounts for the pronounced

and after pumping it through the various tub-

dip in the curves around 150200 hr for the 50-ft

ings. Appendix Table B1 also shows the results of

length of PP1 or 100-ft length of PP2. It may be

the statistical analyses.) The two fluoropolymers,

due to breakthrough of the TCE through the tub-

PVDF and P(VDF-HFP), were clearly the least

ing walls to the atmosphere.

sorptive tubings tested. Sorption of TCE by these

These results agree well with the results from

two fluoropolymers was always 5% or less, even

our static study (Parker and Ranney 1996). That

for the 100-ft sections. For the other polymers,

is, among the tubings tested in this study, the

sorption was minimal (< 10%) for the 10-ft sec-

plasticized PP tubings sorbed the most TCE and

tions of tubing but became substantial when

the fluoropolymers were the least sorptive.

longer tubings (50 ft and 100 ft) were used. Loss-

Based on these findings, it appears that LDPE

es were greatest initially but then approached

could be used to sample TCE if there is an ade-

some type of equilibrium value.

quate equilibration period. This does not appear

For LDPE, initial losses of TCE were 20% for

to be true for the plasticized polypropylene tub-

the 50-ft and 35% for the 100-ft lengths. However,

ings. Because there would be a substantial cost

these losses were reduced to ~5% after 4 hr of

savings if LDPE tubing could be used, the next

pumping for the 50-ft lengths and after 24 hr for

experiment was designed to see how much TCE

the 100-ft lengths. It appears that the tubing and

would be lost with a much longer length of LDPE

TCE-contaminated water reached equilibrium at

tubing (500 ft) and when equilibration might be

these times. The large losses observed initially

expected. A five-hundred-foot well would be one

were most likely due to adsorption on the poly-

of the deeper wells one might sample, but cer-

mer surface. The residual losses that were found

tainly not the deepest.

at equilibrium most likely resulted from diffu-

sion through the polymer matrix.

Sorption findings for the second study

The pattern of losses was similar for the two

Figure 8 shows the mean relative concentra-

plasticized polypropylene tubings (PP1, PP2).

tion of TCE in water that was pumped through

However, losses were much greater for these

500 ft of LDPE tubing at a flow rate of 100 mL/

9

Previous Page

Previous Page