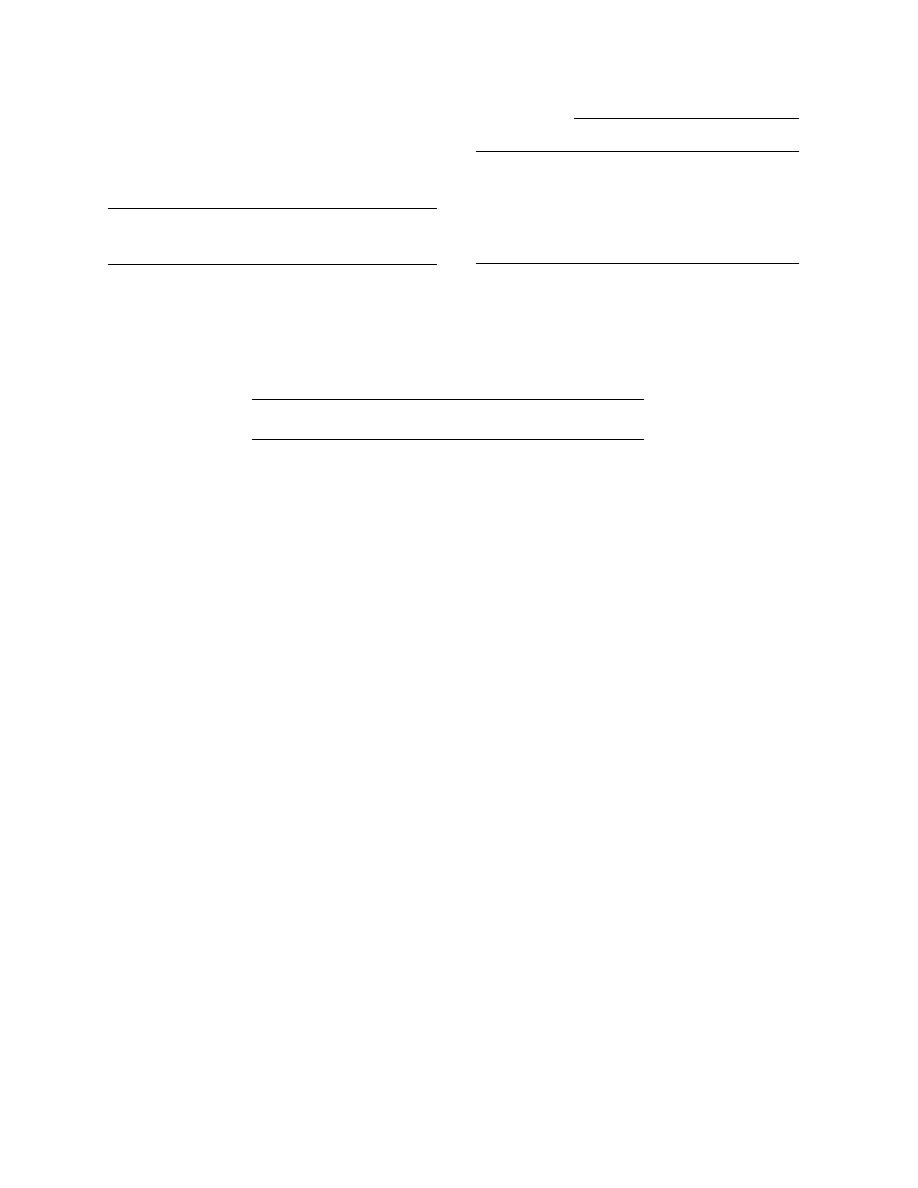

Table 21. Equivalent insulation test results.

Compressive strength--MPa (psi)

Table 20. Durability factors for Pozzutec 20 and

Mixture ID

7 days

14 days

28 days

EY-11 concrete.

3,0,10 (control)

27.9 (4052)

39.8 (5767)

43.8 (6348)

3,2,5

32.4 (4691)

36.7 (5326)

39.8 (5771)

Dosage

3,2,2

30.6 (4439)

32.3 (4685)

35.3 (5112)

60 (90)

100 (150)

3,2,2

26.5 (3846)

35.7 (5170)

38.2 (5543)

Admixture

None

mL/kg (fl oz/cwt)

mL/kg (fl oz/cwt)

3,3,5

33.0 (4778)

36.9 (5349)

42.1 (6098)

Control

99

3,3,2

30.8 (4465)

34.1 (4941)

35.8 (5190)

Pozzutec 20

99

Failed

3,3,2

26.3 (3817)

34.3 (4970)

38.8 (5628)

EY-11

98

96

Table 22. Equivalent insulation values for 152-mm- (6 in.)

thick wall maintained at 10C (50F) for seven days.

Air temperature Required thermal resistance Equivalent fibrous

C (F)

m2 K/W (hr ft2 F/Btu)

Mixture

glass--mm (in.)

3,2

1 (30.2)

1.1 (6.5)

50 (2.0)

3,3

1 (30.2)

1.1 (6.5)

50 (2.0)

present. It appears that the higher dosages of these

PHASE IV: FIELD APPLICATION

admixtures may decrease the chloride threshold.

Procedure

Task 3: Durability

The objective of Phase IV was to validate the

The freezethaw durability of concrete made

EY-11 admixture developed in Phase III by means

with Pozzutec 20 and EY-11 was tested using

of a field trial. Special attention was given to work-

ASTM C 666, Procedure A, and evaluated accord-

ability, finishability, temperature records, and

ing to ASTM C 494. Table 20 shows the results. As

strength development.

happened in Phase I, Pozzutec 20 passed the du-

The prototype admixture (EY-11) was tested

rability test at a dosage of 60 mL/kg (90 fl oz/

outdoors at CRREL, Hanover, New Hampshire,

cwt) but not at 100 mL/kg (150 fl oz/cwt). EY-11,

and at the Corps of Engineers Soo Locks, Sault

on the other hand, showed very high durability at

Ste. Marie, Michigan, during February and March

both dosages.

1994. The CRREL site was chosen because of its

proximity to testing facilities and because it pro-

Task 4: Equivalent insulation

vided a location convenient for long-term moni-

The purpose of this task was to determine the

toring of the concrete. The Soo Locks was attrac-

amount of insulation that EY-11 can replace in a

tive because it provided an opportunity to

420 kg/m3 (705 lb/yd3) cement factor mix. Table

compare normal winter concreting to concreting

21 presents the strength results at various low

with antifreeze admixtures. The timing at each

temperatures. Since EY-11 does not enhance the

site was determined from weather records and

late age strength of concrete (Phase III, Task 1)

forecasts that promised weather conditions ap-

propriate to the 5C (23F) capability of the ad-

when cured at room temperature, the effect of

EY-11 was evaluated only at the seven-day

mixture. A technical representative from MB was

strength. EY-11 was found to increase compres-

on hand to evaluate the effectiveness of the ad-

sive strength relative to 10C (50F) down to ap-

mixture with the cements used at each site. CRREL

proximately 1C (30F) for both dosages.

personnel provided instrumentation for monitor-

Table 22 shows that EY-11 is equivalent to a

ing temperatures and helped measure properties

of the fresh and hardened concrete. Pozzutec 20

Btu), or about 50 mm (2 in.) of fibrous glass insu-

was used to batch a separate mix of concrete for

lation.

comparison purposes.

17

Previous Page

Previous Page