120

Table 19. Harmlessness corrosion results.

a.

Control

Dosage

Current

(20 C)

A/cm2

Admixture

mL/kg (fl oz/cwt)

80

Pozzutec 20

30 (45)

0.539

EY11

Pozzutec 20

60 (90)

0.405

( 5 C)

EY-11

50 (75)

0.724

EY-11

100 (150)

0.651

40

ACI

(5 C)

der and protruding from the top. The test area of

the rebar is limited to 30 cm2 (4.7 in2) by epoxy

0

120

paint. The specimens were cured for four days in

b.

saturated calcium hydroxide solution to within

12.7 mm (0.5 in.) of the top surface. They were

80

then kept at a potential of +260 mV vs. a saturated

calomel electrode. The current flowing through a

1000-ohm resistor placed in the circuit is mea-

sured at regular intervals by voltage drop across

40

the resistor. If the current density is below 1 A/

cm2, the admixture is considered not harmful.

Table 19 shows the results for Pozzutec 20 and

0

EY-11. Both admixtures provided results below 1

10

20

30

Age (days)

A/cm2, indicating that neither admixture caused

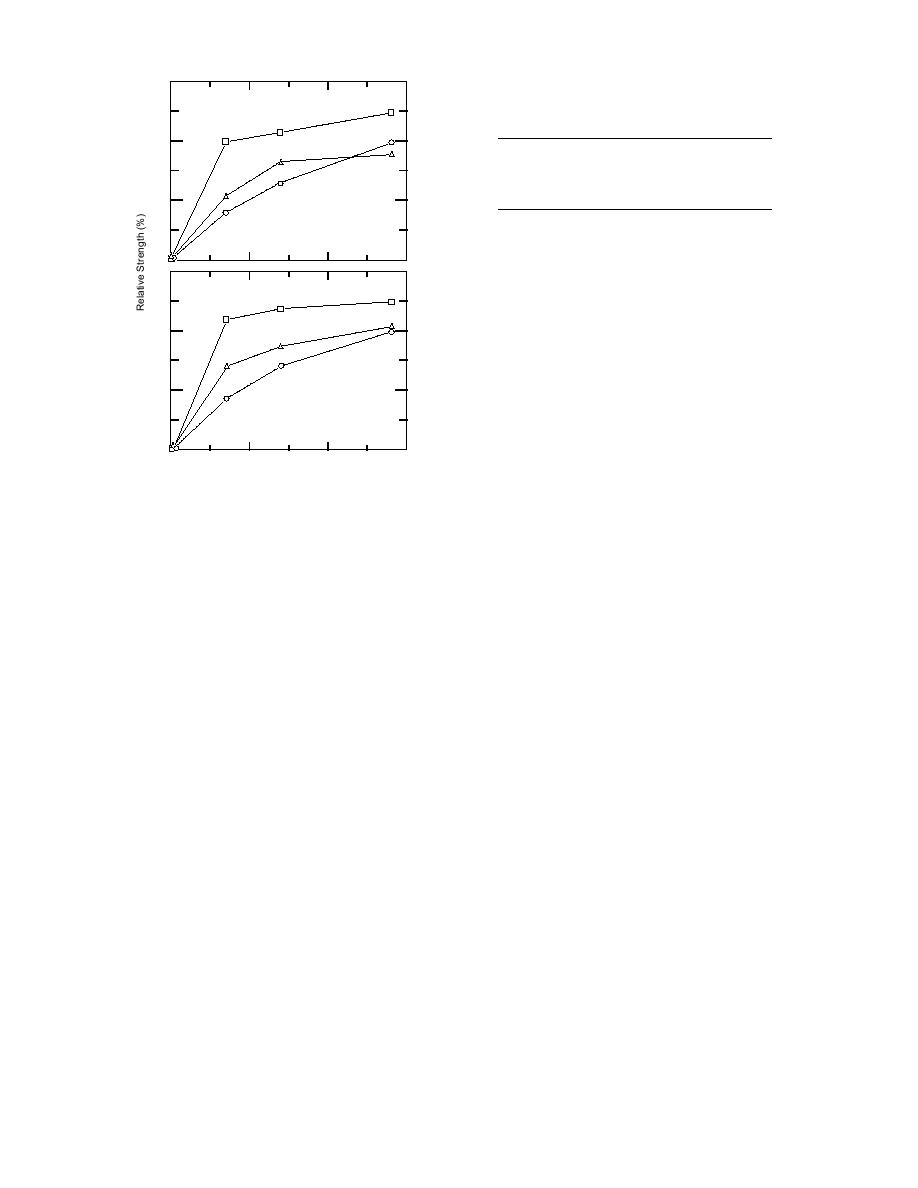

Figure 6. Strength gain of concrete made with

corrosion at the dosages used.

EY-11 cured at 5C (23F) compared to con-

One of the corrosion measuring methods used

trol concrete cured at two above-freezing tem-

in Phase I to measure the potential of Pozzutec 20

peratures. The line denoted as ACI (5C) is

to initiate corrosion damage to embedded steel

based on guidance provided by ACI (1988).

rebar, the Lollipop Corrosion Test, was again used

That line represents the minimum curing con-

to measure the potential of EY-11 to initiate corro-

dition used by the construction industry today.

sion. Two dosages of EY-11 were used (60 and

Figure 6a is for concrete containing a 365-kg/

100 mL/kg [90 fl oz/cwt]), the result being com-

m3 (611 lb/yd3) cement factor and a 100-mL/kg

pared in the same test with the same two dosages

(150 fl oz/cwt) EY-11 dosage. Figure 6b con-

of Pozzutec 20 and two references without ad-

tains a 420-kg/m3 (705 lb/yd3) cement factor

mixture. The specimen size was 75- 150-mm (3

and a 100-mL/kg (150 fl oz/cwt) EY-11 dosage.

6 in.) cylinders, each concrete mix being prepared,

and the concrete specimens cured and otherwise

treated, in the same manner as were the earlier

lollipop examinations of Phase I, except that 15%

to warm conditions. The 100-mL/kg (150 fl oz/

sodium chloride solution was used for ponding

cwt) dose with the 420-kg/m3 (705 lb/yd3) ce-

in place of the 3% solution of Phase I; weekly

ment factor exceeded the ACI reference strength

measurements were taken. Figure 7 shows that

at all ages (Fig. 6b).

EY-11 caused corrosion to be initiated at about

week 12 with the higher dosage (100 mL/kg, 150

Task 2: Corrosion potential

fl oz/cwt) and around week 43 with the lower

The potential of EY-11 to corrode steel rein-

dosage (60 mL/kg, 90 fl oz/cwt). Pozzutec 20, on

forcement was tested according to the so-called

the other hand, was found to initiate corrosion at

"Harmlessness Test" (modeled after a German

earlier times, at about week 6 with the higher

DIN standard according to discussions during

dosage and week 23 with the lower, each dosage

meetings of ASTM Committee G-1.14 199495).

causing initiation to occur earlier by about one-

The method employed in this project uses small

"lollipop" cylinder specimens measuring 50 100

half the time period. Two admixture-free refer-

mm (2 4 in.). The mortar used Type I cement, an

ence specimens were shown to have initiated cor-

ASTM C 109 sand in a 1:3 cement:sand ratio and a

rosion at weeks 39 and 43 for an average of 41

0.50 w/c. The embedded rebar is a No. 4 axially

weeks for the two references. The trial admixture

EY-11, therefore, was found in this 75- 150-mm

located 25.4 mm (1 in.) off the bottom of the cylin-

15

Previous Page

Previous Page