As a result we concluded that some type of liner

1.4

was required for the settling pond. We briefly in-

vestigated the feasibility of using a geosynthetic

S = 100% for Gs = 2.35

liner, but cost and availability considerations led

1.2

us to explore other options to reduce the potential

infiltration into the EOD pad. We were made

aware of a peaty silt material that was available in

1.0

abundance near Fort Richardson. This material

In-situ

appeared to have a very high organic content,

Water Content

making it unsuitable for most engineering projects.

0.8

However, since this material was readily available,

20

30

40

50

60

we decided to evaluate its suitability as a liner for

Compaction Water Content (%)

the settlement pond.

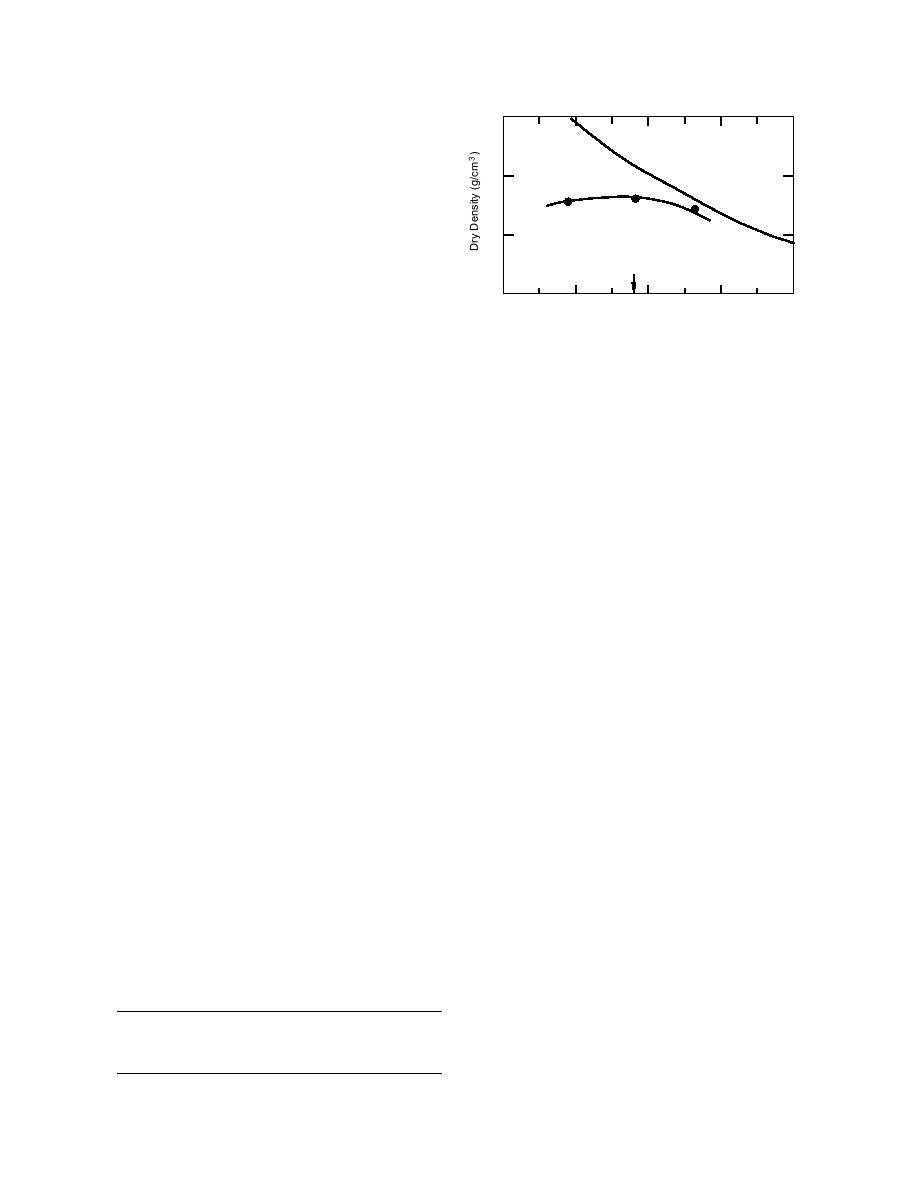

Figure 11. Results of Proctor tests of peaty silt.

To do this we subjected samples of the peaty

silt to compaction and hydraulic conductivity tests

in the CRREL laboratories. The laboratory com-

paction (standard Proctor) and hydraulic conduc-

creasing stress level. The results (Fig. 12c) for the

tivity tests were conducted according to ASTM

test specimen with a water content of about 29%

(9% below optimum) did not pass the 1 105 cm/

standard methods D 698 and D 5084, respectively.

The compaction water contents ranged from about

s litmus test. This was not unexpected, as accord-

29% to about 46%, bracketing the initial in-situ (in

ing to Lambe and Whitman (1969) the hydraulic

the borrow pit) water content estimate of about

conductivity for fine-grained soils significantly in-

38%. The results of the compaction tests are tabu-

creases at water contents below the optimum level.

lated in Table 6 and shown in Figure 11. The opti-

The importance of this finding is that the field

mum water content for the peaty silt material is

water content during compaction must be near or

about 38%, the same as the expected in-situ water

above 38%. This appeared to be no problem as the

content. This result appeared fortuitous, because

water content in the borrow pit was estimated to

it meant that we might not have to make a special

be 38%.

effort to adjust the water content of the peaty silt.

Laboratory hydraulic conductivity tests were

Field tests

conducted for the same water content regime as

The first field tests were conducted in the natu-

the compaction tests. The tests were conducted for

ral gravel surface of the pad. The second tests were

conducted through a layer of sludge obtained from

effective stress levels of 7, 14 and 35 kPa (1, 2 and

the Eagle River Flats, and a third test through two

5 psi) to determine the effectiveness of increasing

layers of sludge sediment. A fourth test was per-

thickness (e.g., increasing stress) as the sediment

formed through a peaty silt layer compacted on

thickness increases during the dredging opera-

the gravel surface inside the test chamber (barrel).

tions. The results are tabulated in Table 7 and il-

Later tests were conducted directly in the peaty

lustrated in Figure 12. The two tests conducted at

silt once it was compacted in the retention basin.

38% and 46% (above optimum) water content

The locations of these initial in-situ tests are shown

showed hydraulic conductivities less than

in Figure 13.

The site for the first series of tests was selected

to be representative of the EOD pad. Modified bar-

rels were used for the test chambers. The bottoms

of 82.5-L steel barrels, 40 cm in diameter and 64

Table 6. Laboratory compaction test results for

cm high, were removed and the barrels were set

peaty silt.

into the test pad as illustrated in Figure 14. The

barrels were set into circular channels cut carefully

Water

Dry

into the pad to about a 15-cm depth. The annular

Sample

content

density

(g/cm3)

number

(%)

space between the outer barrel walls and the gravel

was backfilled with a wet mixture of sand and

PS-3

28.8

1.116

bentonite clay to prevent leaking of the water

PS-1

38.2

1.130

placed in the barrel for the infiltration tests. The

PS-2

46.4

1.087

interior annulus was refilled with a mixture of

15

Previous Page

Previous Page