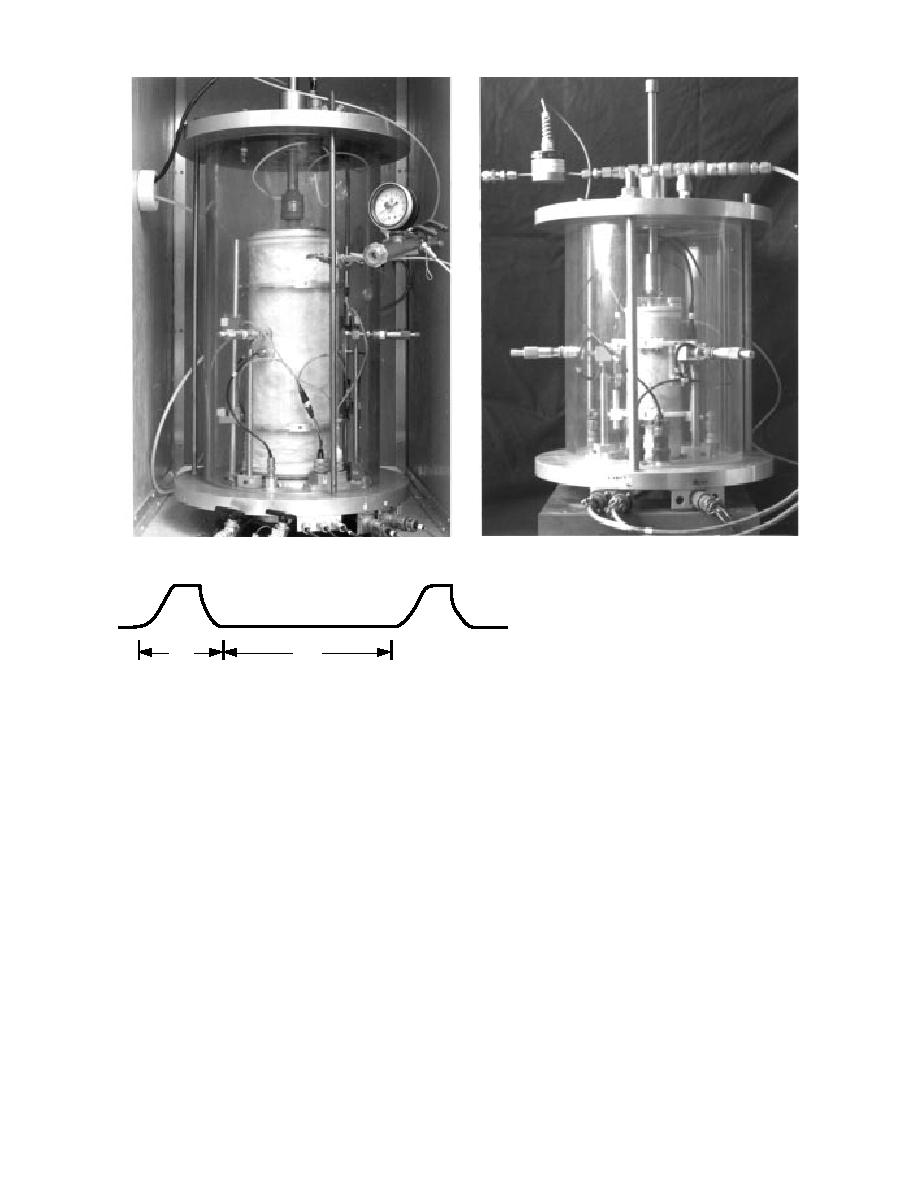

Figure 1. Examples of triaxial cells. Cells for 15.2- (left) and 5.1-cm-diam. specimens.

2.0C (23.0, 26.6 and 28.5F); all other

specimens were tested at 7.0, 5.0, and

2.0C (19.5, 23.0 and 28.5F). The cy-

clical deviator stress was applied at each

1s

2s

test point until the resilient axial strain

Figure 2. Waveform used in Mn/ROAD resilient

modulus

remained a constant value, which occurred

testing.

at about 70100 applied cycles.

Once the tests on the frozen specimens

For this study, the waveform used to apply the

were completed, they were allowed to thaw in the

cyclic deviator stress was the waveform shown in

triaxial device and subsequently retested in a

Figure 2. The pulse length is approximately 1 sec-

thawed, saturated state. For the coarser-grained

ond with 2 seconds between pulses. Table 3a illus-

materials, the specimens were then allowed to drain

trates the sequence of stress conditions applied to

in place, and tested again. Increasing amounts of

the unfrozen specimens, whether thawed or never

suction were applied to the base and subbase speci-

frozen. We applied only the stress combinations

mens to bring them to various moisture states, and

that would avoid excessive permanent strains in

additional test points were determined.

the specimens (5% decrease in axial length), de-

pending on the moisture condition and estimated

Previously tested materials

available strength. The frozen specimens were

In order to conduct the follow-on modeling of

tested holding the confining pressure constant at

predicted damage at the test sections of the Mn/

69 kPa (10 lb/in.2) and varying the deviator stress

ROAD facility, resilient modulus characterization

as shown in Table 3b. The frozen specimens were

was needed for two additional Mn/DOT subbase

tested at three temperatures: class 6 special speci-

materials, class 4 special and class 5 special. We

mens were tested at approximately 5.0, 3.0, and

looked through CRREL's collection of material

5

Previous Page

Previous Page