60

likely that this system will be used in

future ships, because it offers good

maneuverability in broken and intact

Fixed Pitch

ice.

Controllable Pitch

The selection of a suitable propul-

40

sion system is based on the intended

functions of an icebreaking vessel.

The requirements of a propulsion sys-

USSR

tem are:

Polar

SA-15

LASH

Star

1. Reliability of full power on de-

20

mand to navigate safely in the

Icebreaking

Dredge

Arctic.

2. Flexibility of operating effi-

ciently and economically in

open water as well as in heavy

0

2

6

8

10

4

ice at a range of power levels.

Propeller Diameter (m)

3. Maneuverability to allow rap-

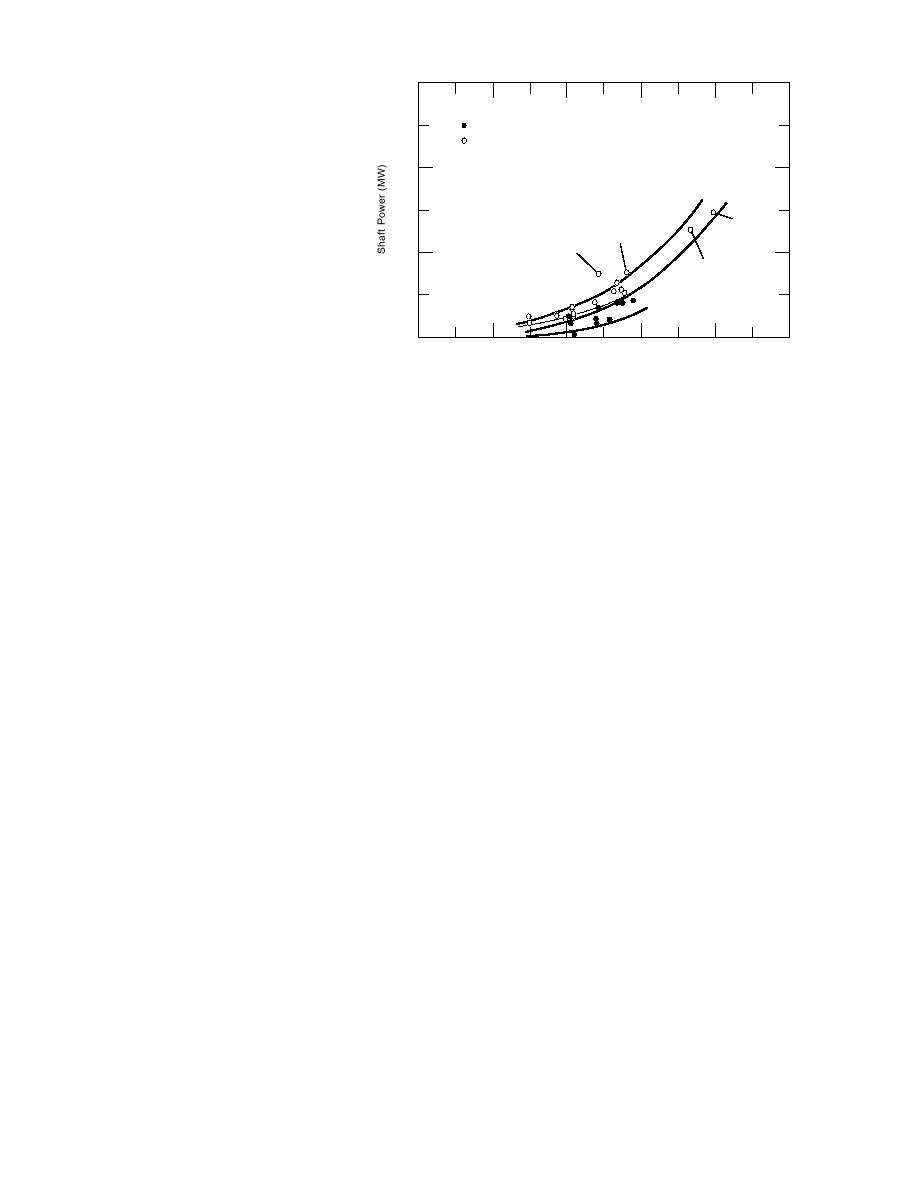

Figure 16. Shaft power vs. propeller diameter for icebreaking ships (af-

id change of load, speed and

ter Dick and Laframboise 1989).

power.

4. High power-to-weight ratio to

deliver the required power, with machines

geared, may use controllable-pitch propellers to

as compact and light as possible.

obtain astern thrust and to ease over-torque

While many combinations of prime movers,

requirements. Reversing systems, such as any of

transmission systems and propellers may be pro-

the electrical systems, may used fixed-pitch pro-

posed for a given ship, very few particular sys-

pellers because over-torque does not affect an elec-

tems would fit a given mission profile (Dick et al.

trical system.

1987). Ships requiring a large range of power can

The design requirements of a propeller depend

be fitted with multiple engines or combined-sys-

on the mission profile of a vessel. The aspects in-

tem installations, which permit the numbers of

fluencing the design of a propeller are (Dick et al.

engines to be run according to the power require-

1987):

1. Loads and strength requirements.

ments of various ice conditions, to achieve the best

2. Selection of material.

combination of fuel efficiency and performance.

3. Effects of nozzles.

In the following sections, a brief discussion is given

There are two types of interactions between ice

of each of the main components of a propulsion

and propellers: ice milling and ice impact. Ice mill-

system.

ing takes place when an ice block is large or is

trapped between the hull and the propeller. Dur-

Propellers

ing an instance of milling, ice is either crushed or

Both fixed-pitch and controllable-pitch propel-

sheared by the blades, and the loads can be dam-

lers have been installed on polar ships. Fixed-pitch

agingly high. Ice impact is caused by small-size

propellers have been used for many years, and

ice pieces that are accelerated through a propeller

these are still being installed on most icebreaking

or thrown out radially and pushed around the edge

ships. However, controllable-pitch propellers have

of the propeller disk. The loads from ice impact

been used on polar ships with increasing frequency

are relatively moderate, but it happens more fre-

since 1966 (Dick and Laframboise 1989). A plot of

quently.

shaft power versus propeller diameter is shown

For propellers in a nozzle, the chances of ice

in Figure 16, where fixed-pitch and controllable-

pitch propellers have been identified. The azimuth

generated are also small in comparison to those

thruster units installed on the Finnish icebreakers

for open propellers. The factors that influence the

Finnica and Nordica have fixed-pitch propellers in

ice loading on a propeller have been identified, but

a nozzle.

the ability to determine the ice millingimpact

The selection of propeller type depends on the

loads is not well developed because of the com-

propulsion system used. Nonreversing transmis-

plex interaction between ice and propellers. The

sion systems, such as dieselgeared or gas turbine

16

Previous Page

Previous Page