The proposed CASPPR allow a certain amount

icebreaker Ymer in 1933. Although this system is

of plastic deformation of the structure under ex-

still being used on many icebreakers, new me-

treme ice loads, and they provide factors to account

chanical and electrical transmissions have been in-

for the post-yield buckling of stiffened structures.

troduced on newer icebreakers and icebreaking

DesRochers et al. (1994) compared the stability of

cargo ships. Since 1966, the number of ships with

flat bars with that of angle sections in a stiffened

controllable-pitch propellers and mechanical trans-

structure. When a structure is designed for buck-

missions is steadily increasing. The Russian LASH

ling according to linear analysis, flat bars are

vessel Sevmorput, delivered in 1986, placed all of

avoided because angle sections have large mo-

its propulsion power on one shaft using a control-

ments of inertia to resist bending. However,

lable-pitch propeller and mechanical transmission,

DesRochers et al. (1994) found that the use of flat

thus doubling the power transmitted per shaft

bar sections increased the stability of the compos-

from 16.65 to 29.42 MW (Fig. 15b).

ite structure beyond the yield point of the mate-

One of the main reasons to use direct mechani-

rial, whereas the structural stability decreased with

cal transmission is to cut down the losses in trans-

the use of angle sections as yielding progressed

mission. Since 1978, propeller nozzles have been

through the frame. The structure of the Canadian

fitted to icebreakers to increase thrust and to pre-

icebreaking cargo ship Arctic has been redesigned

vent propeller damage by reducing ice ingestion.

according to CASPPR to carry full ice loads with-

Nozzles have been installed on most of the Beau-

out failure.

fort Sea ice managementsupply vessels, whereas

The Swedish icebreaker Oden is the first ice-

Polar Sea and Polar Star have operated in ice with-

breaker designed according to the technology be-

out nozzles since 1976. Recently, azimuth-mount-

hind the proposed CASPPR, making it possible to

ed propulsion units have been installed on the

use a large frame spacing of 850 mm instead of the

Finnish icebreakers Finnica and Nordica and it is

normal 400 mm (Johansson et al. 1994). This has

resulted in considerable cost savings in construc-

35

tion. After the voyage of Oden to the North Pole,

a

inspection of the structural damage revealed some

30

Electrical Transmission

indents in the shell plating between frame stations

DC-DC

25

AC-DC

30 and 76 on both sides, and some deformation in

AC-AC

the side and bottom frames (flange, web and

20

bracket), but this damage was not serious. The

15

damaged frames were reinforced, but the indents

in the steel plates were left as they were (Backman

10

1994).

13

3

6

5

2

4

3

3

15

2

0

PROPULSION SYSTEM

35

b

30

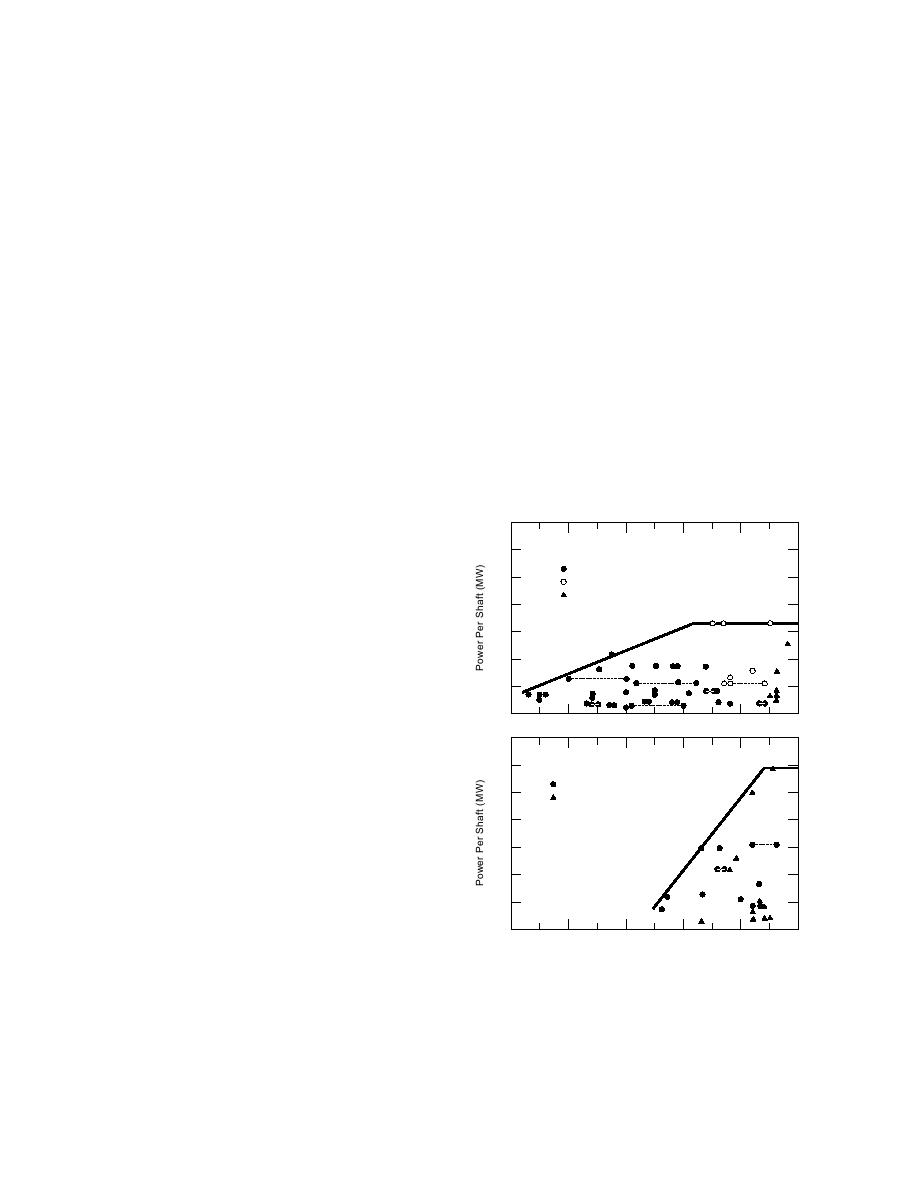

The major components of the propulsion sys-

Mechanical Transmission

tem of an icebreaking vessel, or any ship, are the

CPP

25

CPP in Nozzle

propellers, shafts, transmission systems and prime

movers. The number of propellers varies between

20

one and three. Developments in propulsion sys-

19

15

tems that have taken place during the last four to

five decades are reflected in those of existing ice-

10

4

breakers and icebreaking cargo ships, and these

2

5

become apparent in the plot of shaft power vs. the

0

year of construction (Fig. 15). Some of the special

1940

1950

1960

1970

1980

1990

features of propulsion systems, such as control-

Year of Construction

lable-pitch propellers and mechanical transmis-

sions, nozzles and various electrical transmissions,

Figure 15. Shaft power vs. year of construction for

have been highlighted in Figure 15.

icebreaking ships: (a) electrical transmission system, and

The dcdc electrical transmission has been com-

(b) mechanical transmission system (after Dick and

monly used since its introduction on the Swedish

Laframboise 1989).

15

Previous Page

Previous Page