Welding

8

After selection of steel, welding is the next most

important component in the reliability of the struc-

ture of ships (Dick et al. 1987). Welds in ships must

6

withstand the corrosive effects of seawater, stresses

caused by cargo, icebreaking operations and wave-

P/P

induced motions. The biggest variable in welding

c

4

technology is the skill of the welder, especially

N

when working in confined spaces. To determine

Experimental Results

the reliability of a structure, the designer of a ship

2

must take into consideration the flaws in the ma-

terial as well as in the welds. The importance of

F

A

quality control in welding can be assessed from

C

E

the statistics that 95% of all defects in a structure

0

4

2

originate from defects within the welded zone.

W/t

The fracture toughness of a weld depends on

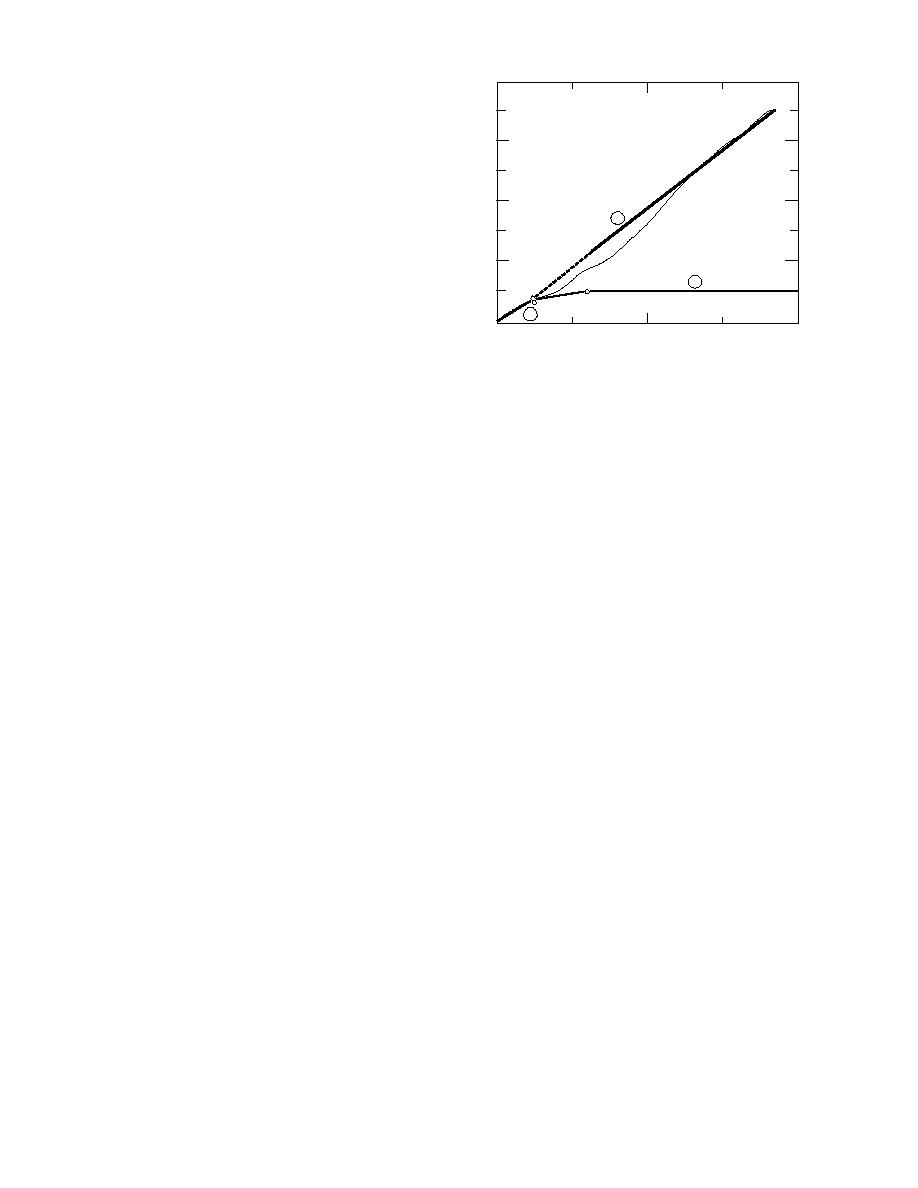

Figure 14. Pressure vs. deflection, showing domains of

the method of weld deposition, including the rate,

different behaviors from small to large deflection (after

the number of passes, heat input and electrode size.

Ratzlaff and Kennedy 1986). Along the vertical axis, the

The variations in weld toughness may be larger

applied pressure P is made nondimensional by Pc, the pres-

than those of the parent materials. Caution should

sure at which collapse (point C) is assumed to take place by

be exercised not to degrade the toughness proper-

formation of three hinges without membrane action. Along

ties of a weld by using large electrodes and fast

the horizontal axis, the maximum deflection W is made non-

rates of deposition in the interests of cost saving.

dimensional by the plate thickness t. The curve labeled E

Research on reducing the accelerated corrosion of

represents elastic flexure with an elastic membrane up to the

welds is under way in different parts of the world.

complete formation of an edge hinge. The curve labeled F

represents elastic flexure without membrane action, followed

Plating

by the formation of the first hinge and then three hinges. The

The plating contributes the largest component

curve labeled N represents ideal membrane action.

to the structural weight of most ships and, together

with the frames and the stringers, it forms the stiff-

ened panels that resist the loads on a ship (Dick et

with respect to the collapse load predicted by the

al. 1987). While the weight of a ship can be reduced

formation of three hinges without membrane ac-

by reducing the plate thickness and by increasing

tion, and the deflection is made nondimensional

the framing, this increases the cost of fabrication.

with respect to the plate thickness. Figure 14 shows

When a rectangular plate supported by frames

that the curve depicting the experimental load-car-

on four sides is loaded by uniform pressure that

rying capacity of a plate is initially close to that

acts perpendicular to its surface, the deflections

predicted by elastic flexure theory for small deflec-

and the stresses in the plate can be calculated by

tions, and then it approaches that predicted by the

the small deflection theory of plate bending, as is

plastic membrane action theory for large deflec-

usually done for structural analysis. This theory

tions. This suggests that thick plates form plastic

ignores the membrane stresses that develop be-

hinges before the membrane action is activated

cause of large deflections and yielding of the ma-

(Ratzlaff and Kennedy 1986).

terial. As a result of ignoring the membrane ac-

tion, the load carrying capacity estimated from

small deflection theory is small compared to those

The frames support the shell plates and resist

obtained from large-deflection theories and experi-

the loads on the shell by bending and shear defor-

ments.

mation. Inspection of ice-damaged vessels has re-

Figure 14 shows plots of load vs. deflection ob-

vealed that failure takes place consistently in the

tained from experimental results and two plastic

supporting frames rather than the hull plating

analyses--one that considers elastic flexure fol-

(Dick et al. 1987, DesRochers et al. 1994). Frames

lowed by formation of three plastic hinges with-

have several components: the shell plate that acts

out any membrane action, and the other that con-

as a flange, a web, an internal flange (optional),

siders only ideal plastic membrane action. The

end brackets (optional), tripping brackets (op-

loads in the plots have been made nondimensional

tional) and cutouts (optional).

14

Previous Page

Previous Page