Table 6. Intrusion volume at given pore diameter (m) and total intrusion volume.

<0.005 0.005 to 0.01 0.01 to 0.05 0.05 to 0.10 0.10 to 0.50 0.50 to 1.0 1.0 to 5.0

5.0 to 10.0 10.0 to 50.0

>50.0 Total

Sample

(%)

(%)

(%)

(%)

(%)

(%)

(%)

(%)

(%)

(%) (mL/g)

4205

8.6

16.4

28.9

15.0

15.3

3.9

5.9

0.5

3.7

1.8

0.0084

3632

11.4

15.4

27.2

6.3

9.7

3.6

8.1

5.9

11.2

1.2

0.0120

4206

8.2

10.6

29.8

14.1

14.4

17.6

1.9

0.3

2.0

1.1

0.0131

3791

6.8

9.0

35.6

14.2

28.3

2.7

1.0

0.2

1.4

0.8

0.0142

3666

5.2

7.2

16.1

15.3

34.7

5.2

8.1

1.6

4.8

1.9

0.0147

3593

6.3

9.2

47.9

26.6

6.2

0.3

0.2

0.0

2.2

1.1

0.0160

3704

7.3

8.2

14.3

7.1

21.7

5.6

19.4

8.2

6.3

1.9

0.0180

3595

4.0

4.5

8.2

2.5

44.7

24.4

9.8

0.2

1.1

0.7

0.0228

4204

7.1

6.4

7.3

3.5

10.4

5.3

15. 1

5.5

28.1

11.3

0.0498

4130

4.6

5.9

12.5

4.3

12.0

4.3

8.8

2.2

18.9

26.3

0.0618

were approximated at 480 dyn/cm and 140 respec-

sample to measure its pore volume between an

upper and lower limit of pore diameter. Since mer-

tively. Tests were conducted according to ASTM

cury is non-wetting, pressure is necessary to get

D4404 (ASTM 1984), except that the aggregates were

dried between 100 and 110C at atmospheric pres-

mercury into the pores. The pressure required to

overcome intrusion resistance is inversely propor-

sure.

tional to pore size according to the well-known

Tests were conducted on four pieces of aggregate

Washburn equation. In lieu of direct measurements,

from each sample subgroup. Values representative

mercury surface tension and contact wetting angles

of the entire sample were developed using weight-

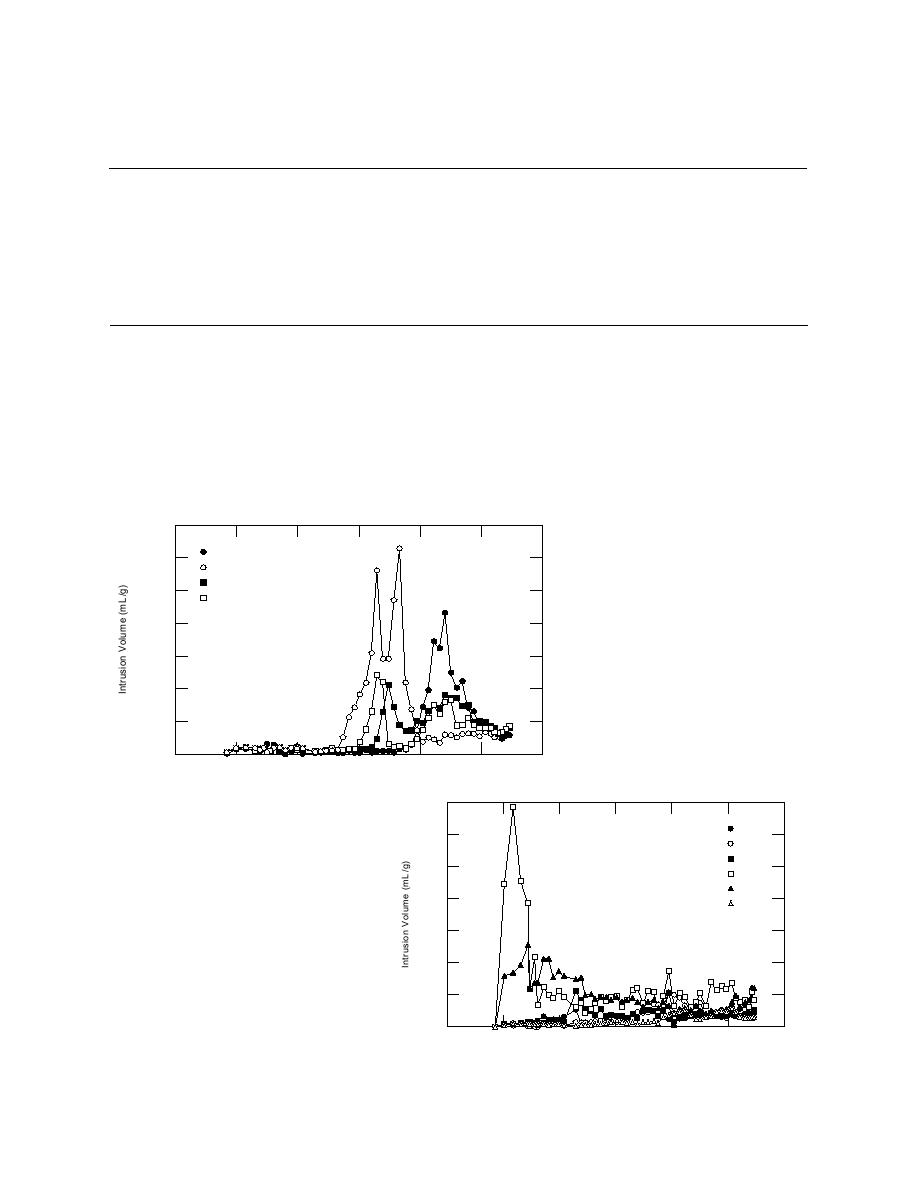

0.0035

3593

0.0030

3595

3791

0.0025

4206

0.0020

0.0015

0.0010

a. Four samples with most of the pore

volume below the 5-m diameter.

0.0005

0

1000

100

10

1

0.1

0.01

0.001

Diameter (m)

0.007

3632

0.006

3666

3704

0.005

4130

4204

0.004

4205

0.003

0.002

0.001

b. Six samples with more evenly distributed

pore volumes.

0

1000

100

10

1

0.1

0.01

0.001

Diameter (m)

Figure 2. Intrusion volume vs. pore diameter.

6

Previous Page

Previous Page