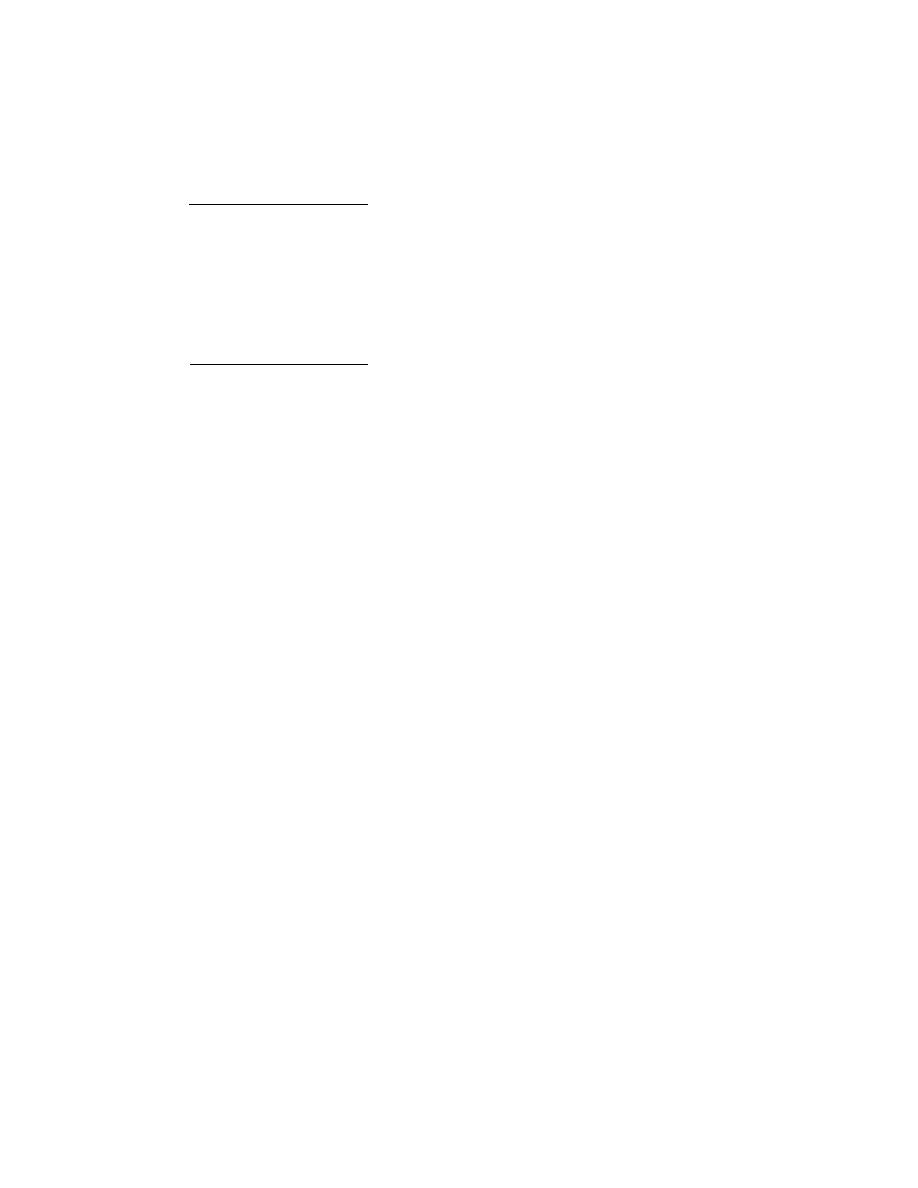

Table 3. Cryogenic frost

sample subgroup and prorating their test results to

damage to two groups of 10

fit the main sample. We picked the latter approach,

aggregate samples in order

as it would provide more potentially useful infor-

of decreasing durability.

mation.

Absorption readings were obtained by selecting

Percent

Percent

pieces of aggregate, four from each sample sub-

Sample

passing Sample passing

group (e.g., four from each of the igneous, meta-

3666

0.08

3989

0.03

morphic and sedimentary carbonate groups were

4205

0.10

4015

0.40

tested from sample 3704) and placing them in a wire

3704

1.07

3987

0.60

3791

1.13

3990

0.76

basket that was submerged in water and suspended

3632

1.43

4014

0.89

from a scale. The weight of water absorbed was

4206

1.53

3991

1.69

recorded every minute. Immediately following each

3593

2.49

3992

1.80

recording, the four pieces of aggregate were mo-

3595

3.94

4033

2.35

mentarily removed from the water to dislodge at-

4204

33.31

4141

2.74

4130

48.44

3035

2.91

tached air bubbles.

The resulting weight readings were corrected to

minute cycle. After 10 cycles the aggregate was

account for differences in aggregate size. When

oven dried at 105C and resieved.

water is absorbed into an aggregate, the weight ab-

The resulting freezethaw deterioration is re-

sorbed at any time is proportional to surface area.

ported in Table 3 as the percentage of original

Thus, for similar materials, absorption rates in larg-

weight passing a 5/8-in. sieve. Loss attributable to

er aggregates having smaller surface-to-volume

the mechanical action of sieving was monitored by

ratios might be different from smaller ones having

sieving a control sample not subjected to freezing

larger ratios. To correct for differences in surface

and thawing.

area, each reading was divided by the surface area

of the four aggregates being tested. (Surface area

was estimated, based on spherical geometry, using

Absorption

Aggregates contain a system of absorptive and

weight and specific gravity data developed during

nonabsorptive pores. The absorptive pores are

the mercury intrusion testing.)

similar to the capillary pores found in hardened

The corrected weight readings were then adjust-

cement paste; they are filled with water by capil-

ed to make them representative of the entire aggre-

lary suction. The nonabsorptive pores are like

gate sample. Each subgroup result was weighted,

entrained air cavities in concrete that can only be

according to its portion represented in the overall

filled by removing the entrapped air and applying

sample, and added to the weighted results of the

an external pressure. The rate at which absorptive

other subgroups from the same sample.

space fills with water provides information about

Thus, all recorded weight data were corrected to

frost-susceptibility. Fine pores of high capillarity

account for surface area variations and adjusted on

usually acquire water more quickly than coarse

a weighted basis to be representative of the entire

pores of low capillarity. Since freezing water caus-

sample. Figure 1 shows how quickly each sample

es distress, aggregate that wets easily and retains

absorbed water when submerged. For example,

moisture strongly is usually more frost-suscepti-

within the first 6 minutes, samples 3666, 3791, 3595,

ble than aggregate that wets slowly and drains

4205 and 4206 achieved nearly 10% of their 24-hour

readily. Modules II and III addressed the total

saturation, indicating that they might have a rela-

absorptive capacity of each aggregate sample by

tively fine pore structure (high capillarity). The

measuring their 1-day through 1-year absorptions.

seemingly coarser grained aggregates showed a

This study examined the initial rate of absorption

more gradual absorption rate. Samples 4130 and

during the first several minutes of wetting as well

4204, the slags, appear to have the coarsest pore

as the 24-hour absorption. For reasons discussed

structure. Table 4 ranks the aggregates by fill rate

from the fastest to slowest based on the 6th minute

earlier, our absorption measurements were made

on only half the materials; in this case, those from

reading and gives their 24-hour absorptions.

the first 10 samples.

Our main problem was obtaining a single ab-

Crushing value

sorption value for each sample. Two approaches

An aggregate's strength and freezethaw dura-

were considered: either constructing a small sam-

bility are both influenced by its internal pore struc-

ture. As freezing occurs, damage progresses from

ple having the identical makeup of the main sam-

internal micro-fissures into larger and larger cracks.

ple, or selecting individual aggregates from each

4

Previous Page

Previous Page