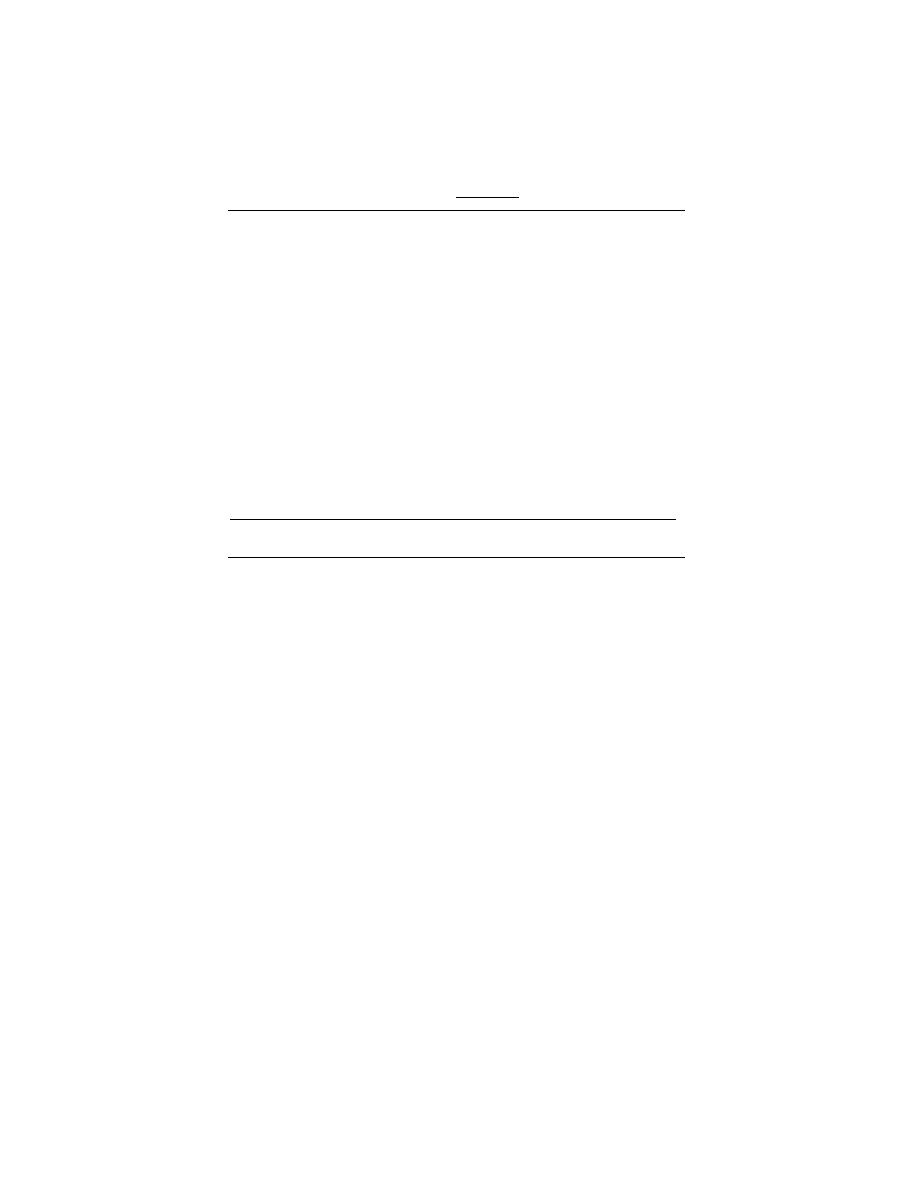

Table 2. Aggregate data by decreasing durability (blast furnace slags

listed separately at the end of the table).

Expansion

Calculated

per 300

equivalent

Sample

Sedimentary All FT cycles

durability

no.

Igneous

Metamorphic Carbonate Soft Chert others

(%)

factor

3704

55.2

32.6

0.0

0.0

0.0

12.2

0.000

100

3987

100.0

0.0

0.0

0.0

0.0

0.0

0.000

100

4205

0.0

0.0

100.0

0.0

0.0

0.0

0.015

88

3632

80.9

9.4

2.9

0.0

1.0

5.8

0.024

81

4014

0.0

0.0

100.0

0.0

0.0

0.0

0.030

77

3666

5.8

2.8

91.1

0.0

0.2

0.1

0.033

75

4015

0.0

0.0

100.0

0.0

0.0

0.0

0.048

66

4141

3.7

4.0

91.9

0.2

0.1

0.1

0.072

54

4033

3.0

0.1

96.2

0.2

0.3

0.2

0.081

50

3595

4.1

0.8

94.5

0.0

0.6

0.0

0.105

41

3990

27.8

22.2

45.0

0.8

4.0

0.2

0.138

32

3035

16.2

5.7

72.8

2.4

2.1

0.8

0.150

29

4206

18.9

24. 1

50.4

0.6

5.6

0.4

0.159

27

3992

21.7

19.4

51.9

2.0

3.8

1.2

0.174

24

3791

17.0

17.6

56.7

1.5

6.2

1.0

0.189

22

3989

21.6

20.5

49.7

1.5

6.2

0.5

0.309

10

3593

0.0

0.0

99.3

0.1

0.6

0.0

0.402

<10

3991

21.7

19.8

47.1

3.6

6.9

0.9

0.468

<10

Vesicular

Vesicular

dense

Dense

Glassy

4204

64.1

20.3

14.4

1.2

--

--

0.003

100

4130

72.4

17.0

9.2

1.4

--

--

0.006

96

of the field situation. Owing to the complexity of

ual pieces of aggregate act similarly in one impor-

accurately simulating field conditions and con-

tant regard: freezing occurs omnidirectionally. In-

straints on time, the MDOT laboratory test method

ward freezing inhibits the escape of water by

approaches this ideal situation by using small-

sealing outer pores of the aggregate with ice at the

scale concrete prisms made with a concrete mix

start of freezing. Consequently, volume increases

similar to that used in the field. It deviates from the

created by freezing of the remaining entrapped

ideal by using more rapid freeze rates than those

water must be elastically accommodated by the

encountered by pavements in nature so as to pro-

aggregate whether freezing is fast or slow.

duce timely results.

Aggregate samples were cryogenically tested

The simplest and fastest way to test aggregate is

using the following equipment: a water bath, a

to leave it unconfined, i.e., not embedded in con-

5/ in. [25, 19 and 16 mm]) and a scale. Aggregate

crete. This avoids the delays and variables inher-

8

ent with mixing and curing concrete specimens.

samples were prepared by thoroughly washing,

Though unconfined freezing does not duplicate

oven drying and separating the aggregate into a

size passing the 1-in. and retained on the 3/4-in.

confinement of aggregate by mortar, the results

are usually considered meaningful as relative

sieve. Smaller sized aggregate was also tested and

measures of aggregate quality.

yielded similar results, which are not reported

We chose to test aggregates separately by modi-

here.

fying AASHTO T-103 (AASHTO 1978), which de-

Testing consisted of soaking approximately

scribes a rapid procedure for freezethaw testing

500 g of the prepared aggregate in water for 24

of aggregates. Instead of conventional refrigera-

hours, followed by freezethaw cycling. Each cy-

tion equipment, we chose liquid nitrogen as the

cle consisted of 1.2 minutes of submersion in

196C liquid nitrogen, followed by a 0.5-minute

freezing medium and instead of room-tempera-

drain period, immersion in 90 to 100C water for 2

ture air, we used hot water for thawing. High

freezing rates can be more destructive to speci-

minutes and another 0.5-minute drain period. On

mens of concrete than are low rates. However, in

the basis of heat transfer calculations, the center of

this instance, the freezing rate was not considered

each piece of aggregate cycled from approximate-

ly 50 to 100C and back again during each 4.2-

a problem as low or high freezing rates on individ-

3

Previous Page

Previous Page