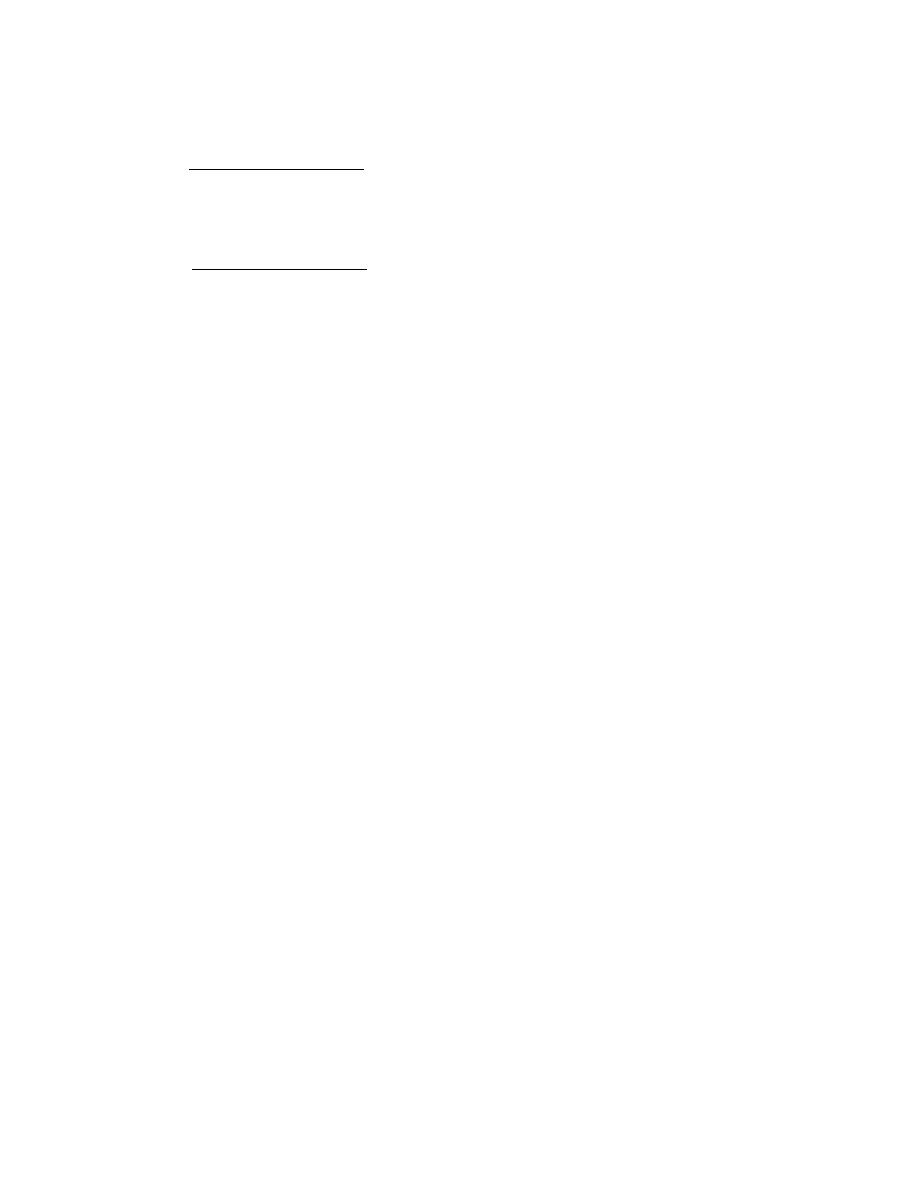

Table 1. Work responsibili-

mechanical strength. Consequently, some effort

ties.

was shifted from solely developing a cryogenic test

method to developing pore size distributions, mois-

Module MDOT

MTU CRREL

ture absorptions and crushing strength data. The

I

X

--

--

cryogenic freezethaw tests were conducted on the

II

--

X

20 aggregate specimens, but funding limitations

III

X

--

--

allowed us to use only 10 specimens for the remain-

IV

X

--

X

ing tests.

V

X

--

--

Vl

X

X

X

Test materials

The overall project consisted of six modules to

The materials were obtained from 20 sources in

be completed over 2 years. Table 1 lists the respon-

Michigan, consisting of gravel, quarried stone and

sible party for each module, for which a brief

blast furnace slag. The materials came to CRREL in

description is given below.

two shipments of 10 samples each. Table 2 provides

Module I--compare the freezethaw performance

MDOT data on sample composition and freeze

of concrete to the moisture gain of aggregates test-

thaw results from conventional tests.

ed according to the Iowa Pore Index Test. The Iowa

Sample composition was determined from petro-

test measures the amount of water injected into

graphic analyses of 300 aggregate particles ob-

aggregate during the first 15 minutes at 35 lb/in.2

tained from material retained on each of four sieves

from 3 4 in. to no. 4 (4.75 to 19 mm). Freezethaw

(241 kPa).

/

Module II--test aggregates for differences in ab-

results were obtained from a set of nine concrete

sorbed moisture under field and laboratory condi-

beams containing approximately 7% air. All were

tions to develop a standard moisture conditioning

made with vacuum-saturated aggregate, except for

procedure for future laboratory testing.

the beams made with the slag aggregate, which was

Module III--test moisture gain in aggregates con-

soaked in water for 24 hours. Expansion readings

ditioned at 100% relative humidity for up to 1 year.

represent the average percentage length change for

This module extends data developed in module II.

the set of nine concrete beams per 100 freezing and

Module IV--evaluate the freezethaw durability

thawing cycles. The calculated equivalent durabil-

of concrete subjected to conventional testing vs.

ity factor is based on beam expansion after 300

aggregates subjected to cryogenic frost cycling.

freezethaw cycles.

Module V--evaluate the effect of using 15.2-

MDOT considers concrete beams to be frost dam-

15.2- 40.6-cm concrete beams and 5. l-cm nominal

aged when their length has increased 0.10% or

maximum-size aggregates as opposed to 7.6- 10.2-

when their calculated equivalent durability factor

40.6-cm beams and 2.5-cm nominal maximum-

reduces to below 70% after 300 freezethaw cycles.

size aggregates in conventional freezethaw test-

Table 2 shows that nine aggregates (3595, 3990,

ing.

3035, 4206, 3992, 3791, 3989, 3593, and 3991) pro-

Module VI--summarize all testing in a report.

duced less durable concrete when evaluated by

either the length-change percent or the calculated

equivalent durability factor, but that three more

EXPERIMENTAL WORK

(4015, 4141 and 4033) produce less durable concrete

This report gives the module IV findings, which

by only the calculated equivalent durability factor.

compare results of the CRREL rapid freezethaw

In general, aggregates with poor laboratory per-

test to the MDOT results from concrete beams

formances had higher proportions of sedimentary

tested in the conventional manner.

material while good performers were dominated

The original intent of CRREL's module IV was to

by igneous material.

develop a cryogenic freezethaw test procedure

that would somehow rank the 20 aggregates from

Cryogenic testing

Perhaps the most realistic way to test aggregate

best to worst based on freezethaw performance.

is to embed it in mortar and to subject it to the

We later modified this plan during the early stages

identical wetting and freezing conditions experi-

of testing when we realized that determining how

the freezing of interstitial water affects aggregate

enced by concrete in the field. In this manner stress-

properties was important for evaluating the cryo-

es from ice buildup within discrete particles of

aggregate and those from water escaping from the

genic results. The main expectation was that dura-

aggregate into the surrounding paste model those

bility would be controlled by pore structure and

2

Previous Page

Previous Page