(ASTM D 4226) and Izod impact testing provides a good indication to the materials ability to

endure both installation and "in-service" impact loading.

Test coupons from drop dart test.

The drop dart test, ASTM D 4226A, is carried out at regular intervals during the

manufacturing process and is an indicator as to how the material will hold up to impact from

blunt objects. An 8-pound or 20.5 pound weight attached to a special shaped dart(C.125 impactor

head for the most abuse) is raised to a given height and dropped onto the face of the sheet. If

impact failure is observed, the drop height is slightly reduced. If impact failure is not observed,

the drop height is slightly increased. This sequence is repeated until at least 20 data points are

obtained. From the data a Mean Failure Height(H) is calculated. Theoretically, the Mean Failure

height is the height where one can raise and release the drop dart device numerous times and note

50% failure and 50% passing. This height is multiplied by the weight of the dart to obtain the

Mean Failure Energy (MFE). MFE is in units of force multiplied by distance(e.g. in-lbs or ft-lbs).

The MFE can be divided by the sample thickness to obtain the Normalized Mean Failure

Energy(NMFE). NMFE is in units of force multiplied by distance divided by thickness(e.g. ft-

lbs/inch). Specifyers should be aware that some manufactures incorrectly express ASTM D 4226

in units of in-lbs/in2. Northstar's protocol on impact testing ensures that the vinyl material

supplied can stand up to the abuses of installation and the harsh marine environment.

Izod Impact(ASTM D 256-00) which was carried out by Applied Testing Services (ISO 9002

certified) measures the ability of the vinyl material to hold up to impact from sharp objects.

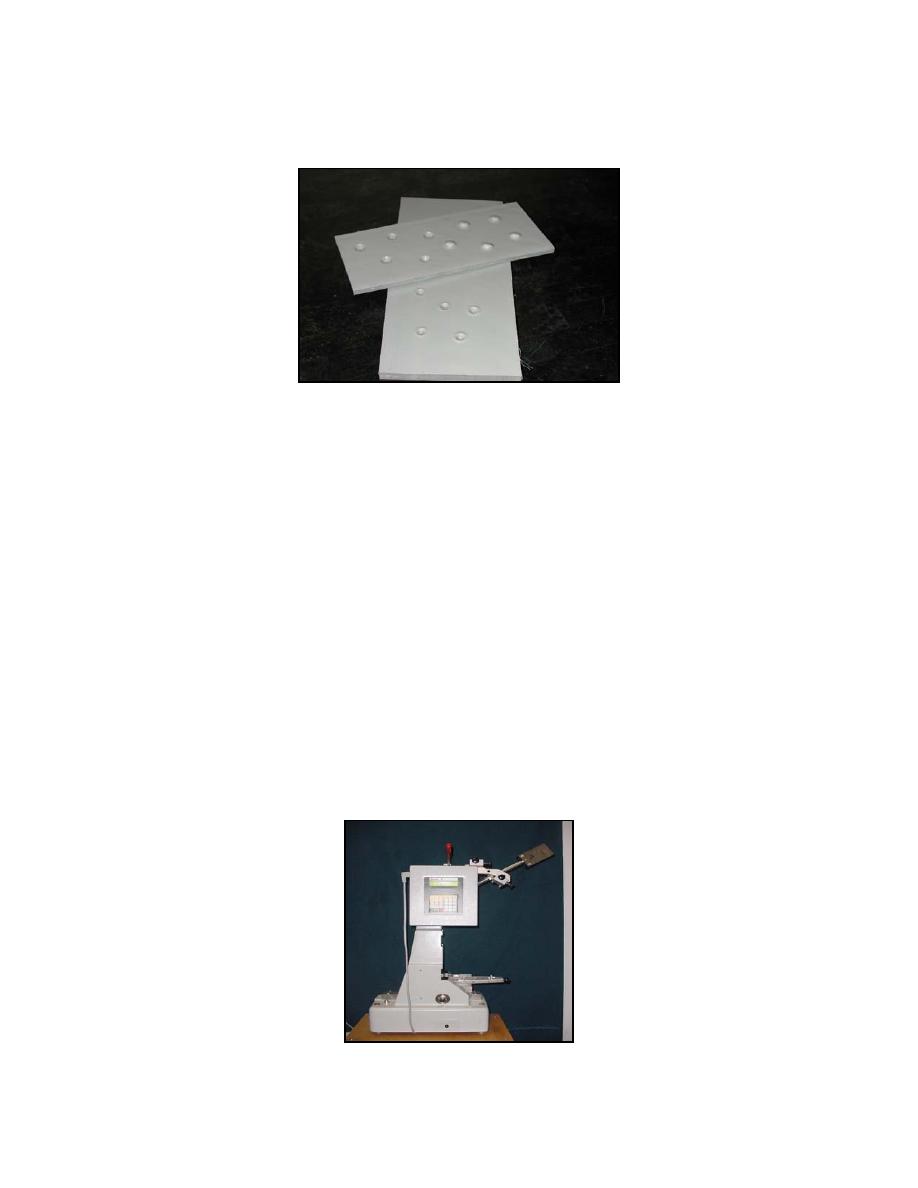

Izod impact testing device.

64

Previous Page

Previous Page