minimum was 7,500 psi and 7,200 psi, respectively. Also from this test, the modulus of elasticity

reported was 380,000 psi, which is important for determining deflections in the retaining

structure. Even though flexural stress models how the sheeting will be loaded in the field,

determination of the sheeting's allowable bending strength is predicated on tensile stress. This

becomes the first tier factor of safety for determining allowable bending stress of the sheeting.

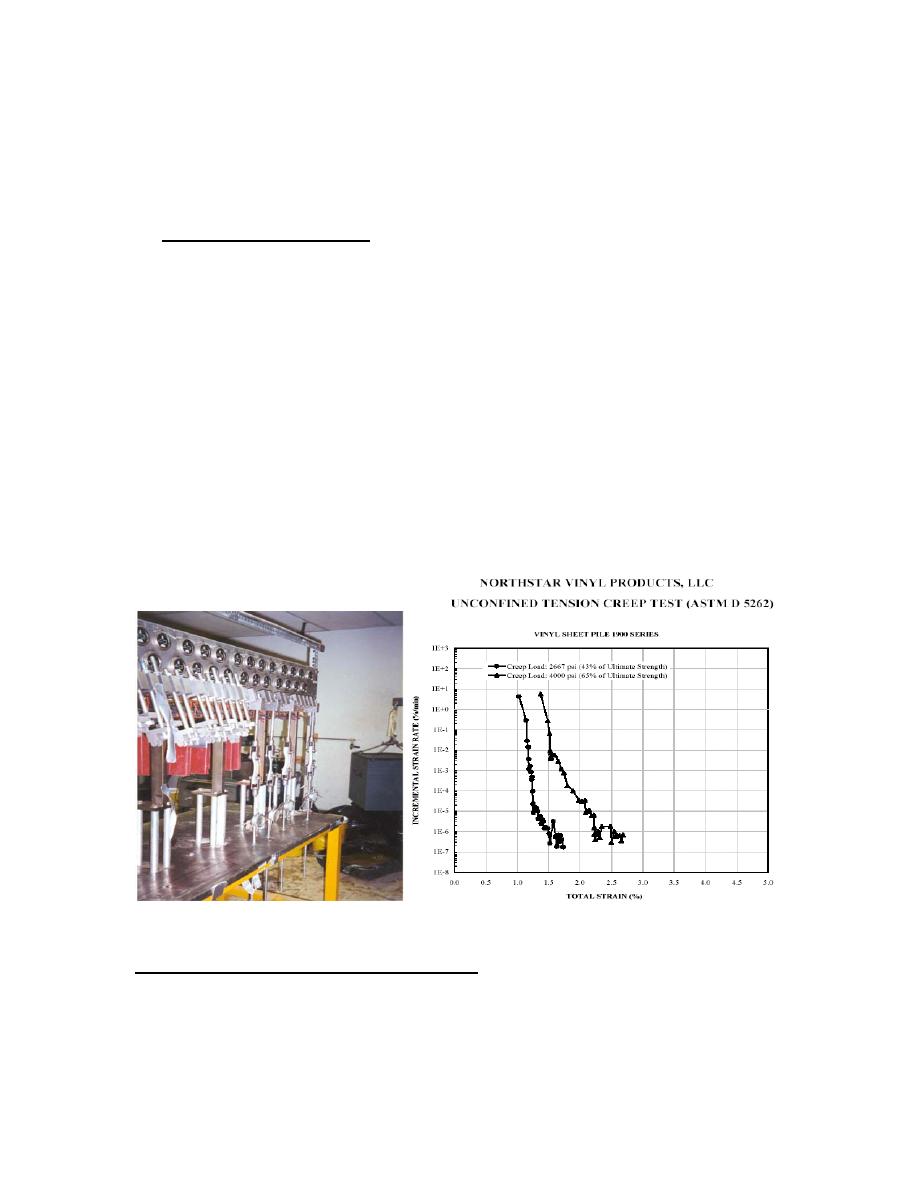

Creep Testing (ASTM D 5262)

Creep is defined as deformation under a constant load(stress). It is possible to load a material

below its yield stress and still fail at some time later. Creep limited stress(CLS) is the maximum

stress at which a material can be loaded and not fail due to creep. Load the material just above the

CLS and the materials strain and strain rate will increase and eventually fail. Northstar has

completed over 15,000 hours of creep testing at 2,667 psi and 4,000 psi for a total strain less than

2% and 3%, respectively. Total strain and incremental strain is plotted against time on a log scale.

This test demonstrates that this formulation and manufacturing method of vinyl has a CLS greater

than 4,000psi. Proof of this can be illustrated by the reduction of the incremental strain, or a

decrease in the strain rate. This demonstrates that the material will not fail in creep at that given

stress level and that the total strain curve is asymptotic.

Therefore, Northstar's Vinyl sheet pile can be loaded to a maximum stress level of 4,000 psi

and the material will not fail due to creep. Aside from the work done by Northstar and Findley &

Wrigley, we know of no other creep testing done in the vinyl industry. Northstar is the only sheet-

pile manufacturer with over 20,000 hours of creep data.

Creep test.

Graph of creep rate.

Impact Strength(ASTM D4226A and ASTM D256)

High impact strength is most important during installation of the sheet-pile. Many projects

utilize impact or vibratory hammers for driving into very stiff soils. After installation, the sheet

pile needs to hold up to possible incidental impacts from small boats, ice, and other debris. Much

of the energy in such a situation will be transferred to the backfill soil. Hence Drop Dart impact

63

Previous Page

Previous Page