our specifications. Periodically during each product run, samples are taken and subjected to Drop

Dart impact testing as defined by ASTM D 4226A in addition to Izod Impact Testing as defined

by ASTM D 256. These impact tests provide a good indication that our finished product is of the

proper cell classification and demonstrates the proper physical properties associated with a

weatherable, external grade vinyl.

Northstar is the only vinyl sheet-piling manufacturer that has orchestrated such an in-depth

testing program by third party industry experts Northstar devotes a significant amount of time and

resources into product testing, because we recognize that seawalls/bulkheads (retaining wall

structures in the marine environment) are demanding structural applications. It is worth noting

that Northstar Vinyl Products conducts testing of its finished product and does not rely solely on

compound data supplied by our vendors.

Confidence in the testing lab is almost as important as the data collected. Tensile, Flexural,

and Creep Testing was carried out by SGI Testing Services (formerly GeoSyntec), which has

certification from the Geosynthetic Research Institute. While impact and UV testing was carried

out by Applied Technical Services, Incorporated which is an ISO 9002 certified laboratory.

Flexural stress (ASTM D 790)

A beam (in this case sheet pile) is supported at each end and a lateral load to induce bending

is applied. One side of the beam (sheet) is in compression while the other is in tensile. This

depicts actual loading in the field due to lateral loading from the soil.

Maximum Flexural Stress expressed as an average and minimum was 8,396 psi and 7,968 psi,

respectively (Span/Thickness ratio = 56.6). Be careful, other manufacturers may overstate their

values by using too small of a span/thickness ratio. If one tests the material with too short a span,

overstated values due to shear will be realized.

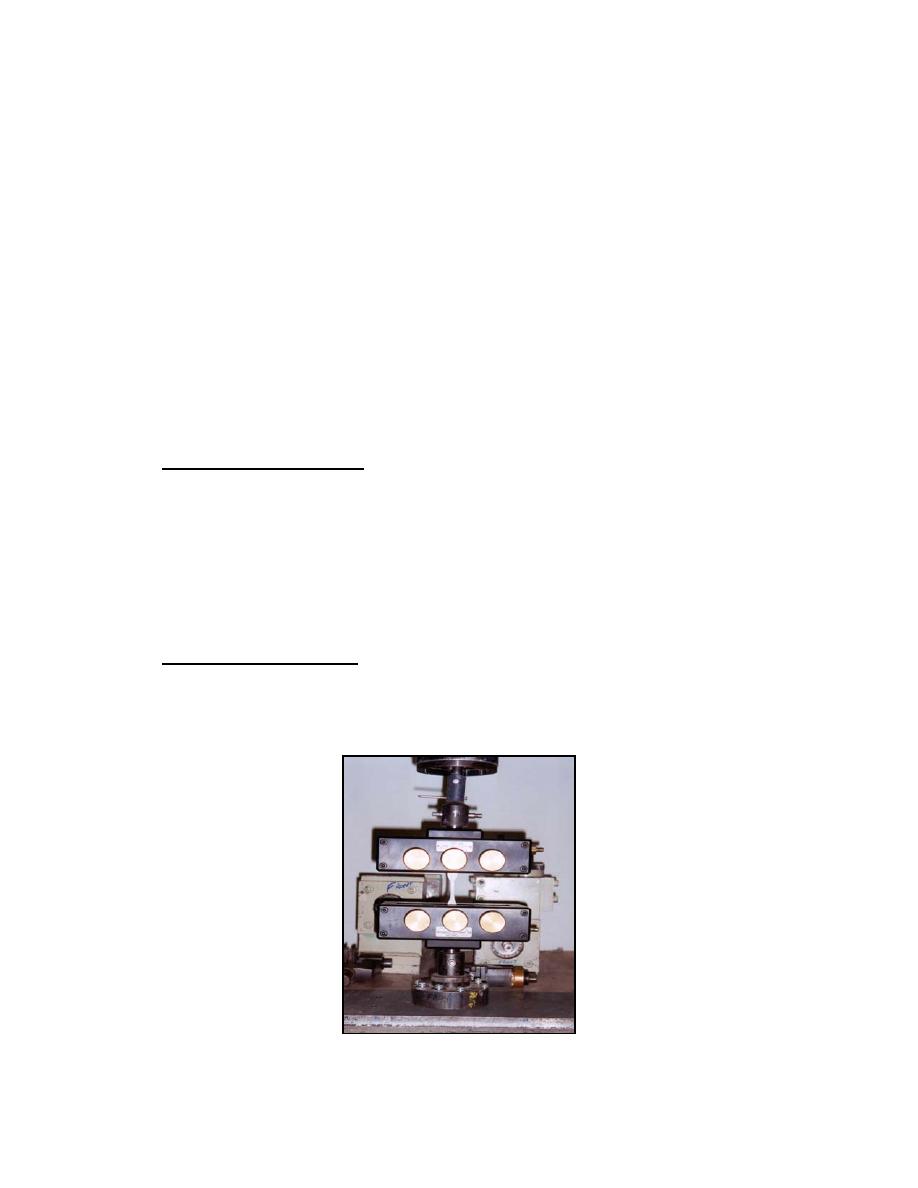

Tensile stress (ASTM D 638)

A tensile test can most easily be described as a "pulling mechanism" that pulls on the

material like a rope. Here, samples of finished sheet pile material are secured at each end and

pulled apart(similar to a chain or rope). Maximum Tensile Stress expressed as an average and

Tensile test.

62

Previous Page

Previous Page