23

DESIGN OF ICE BOOMS

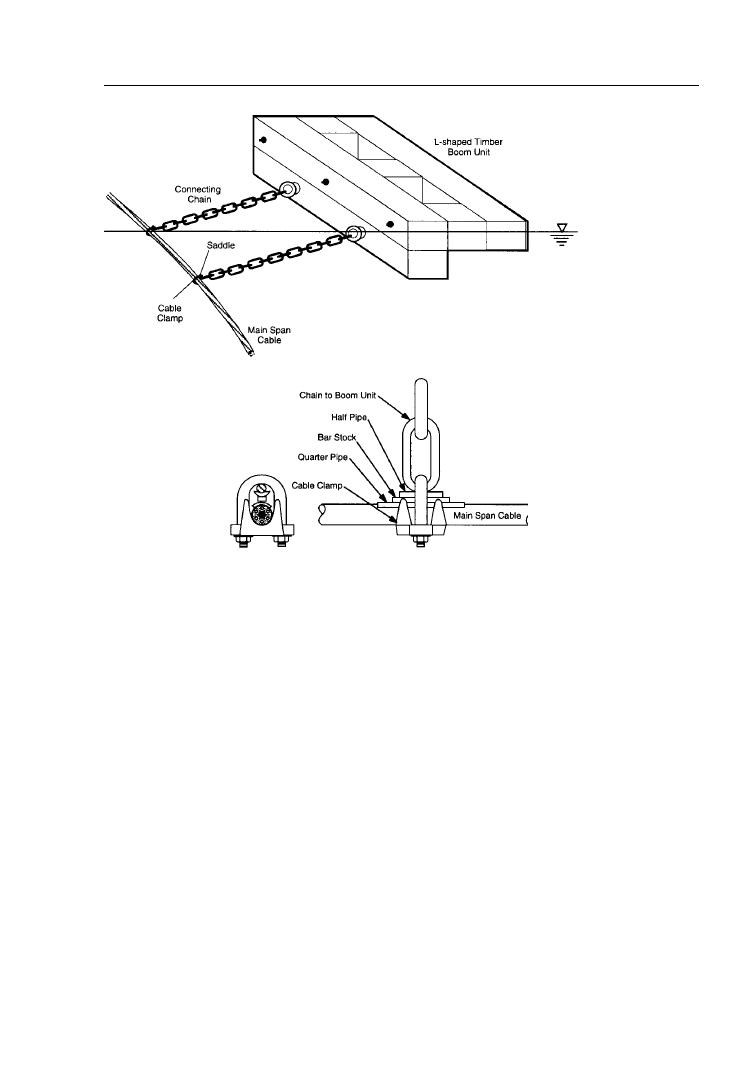

12. Triple timber ice

boom unit, showing

connections to main

cable.

13. Fabricated steel

saddles, designed to pro-

tect the main wire rope

from pinching by the

cable clamps.

section steel pipe booms on the lower St. Lawrence River (Fig.

11d). Plastic tubing has also been used (Fig. 11e). For additional

examples of possible boom cross-sectional geometries, refer to

the Ice Engineering (U.S. Army Corps of Engineers 1982).

Boom unit

The boom unit is generally connected to the main load carrying

connections

cable by a 3- to 5-ft (0.9- to 1.5-m) length of chain or wire rope

(Fig. 12). The location of the chain-to-boom-unit connection af-

fects the righting moment, but structural considerations are equally

important. The boom unit connector chains attach to cable clamps

on the main span cable. Special steel saddles must be fabricated to

protect the main wire rope from being pinched by the cable clamps

(Fig.13). Figure 14 shows standard fittings useful in the design of

ice boom connections. Included are open and closed spelter sock-

ets used to link wire rope to various fittings such as shackles,

chains, and connector plates.

Failure

If one boom component fails, the load on adjacent components

considerations

will increase substantially. A failure analysis should therefore be

made on the multicomponent structure to examine the effect on

adjacent members, should one member fail. Fuse-links, or spe-

Previous Page

Previous Page