COLD REGIONS TECHNICAL DIGEST NO. 96-1

20

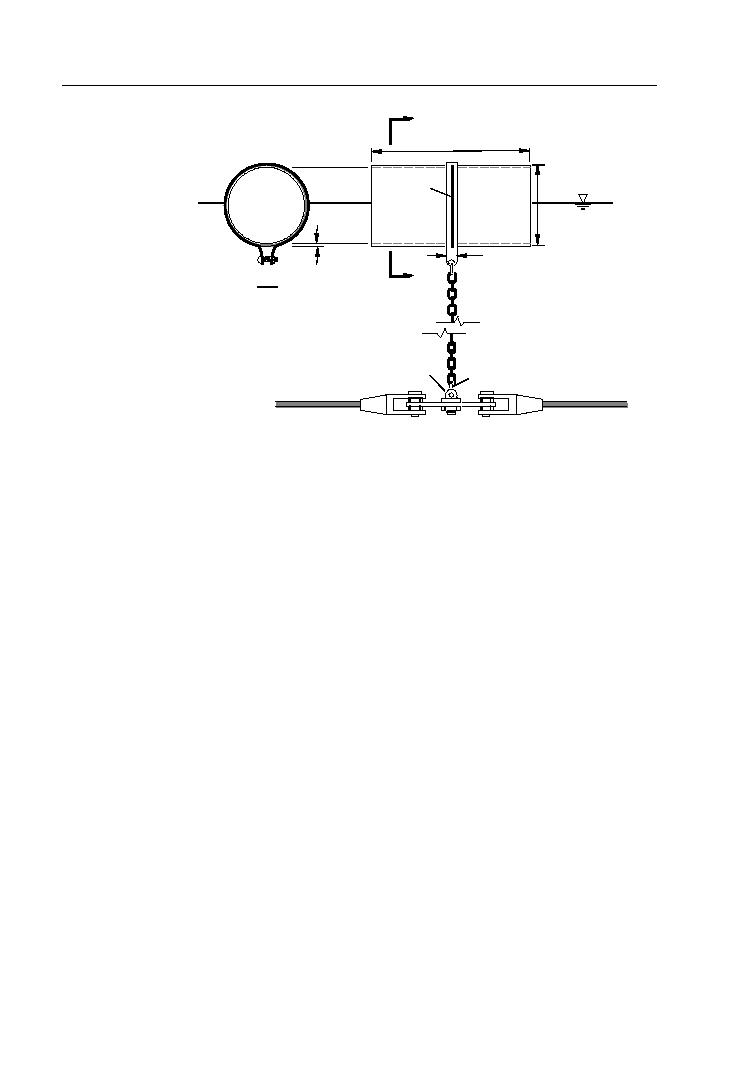

A

5'

(1.74 m)

3'

Stiffener

(0.9 m)

Cylindrical

Buoy

Steel

Band

4"

1/2" (13 mm) Bolt

(102 mm)

2"

A

A-A

(51 mm)

7/8" (23 mm) x 4' (1.22 m) Chain

9. Example of junction

plate and float ar-

rangement. In this case

1 1/2" (38 mm)

a cylindrical float

1" (25.4 mm) Shackle

Eyebolt

supports the junction

2" (51 mm) Boom Cable

plate with a 4-ft (1.2-m)

2" (51 mm)

length of chain.

Wire Rope Socket

Boom unit design

Important considerations in the design of the actual boom units

are the type and thickness of the ice to be retained and the antici-

pated ice forces. The strength of the boom unit is also important,

since a boom unit must resist bending failure under the design

loads, particularly if large floes are expected to impact the struc-

ture. In addition, the boom unit must have sufficient frontal area

to capture floating ice and debris. Size is also an issue, because a

boom unit must be small enough to be easily handled by available

equipment during its annual installation and removal.

Ice restraint

The ice restraint capacity of a boom unit depends on the buoy-

capacity

ancy, the righting moment, the location of the anchor connection,

and the type of ice being retained. Figure 10, based on experimen-

tal data with thin ice covers, shows that a single 1 2 ft (0.3 0.6

m) timber boom, with a scope of 12.5 or more, has a maximum

load capacity in the 80 lb/ft (1.2 kN/m) range, above which the tilt

angle β reaches about 35, resulting in the ice overriding the

boom unit. With thicker, stronger ice covers, much higher loads

are possible, however. Some double pontoon booms have load

capacities as high as 500 lb/ft (7.3 kN/m). Measured force levels

listed in Table 1 give an idea of the maximum ice restraint capaci-

ties of various other types of booms.

Successful ice

Table 1 and Figure 11 illustrate a variety of successful boom

boom designs

unit designs. Many others are possible. For years, single timber

boom units (Fig. 11a) have been successfully used in both large

Previous Page

Previous Page