numerical and experimental data compare well in all five plots. For the uninsulated

pipes, the best agreement between the numerical and experimental data is with

methods 1 and 2, which use eq 37 and 38 to calculate the effective conductivity.

The differences caused by emissivity values can also be seen, with a slightly

reduced heat flux observed for the lower emissivity (condition C). For the insulated

pipes, there is general agreement between all the methods. This occurs because the

thermal resistance due to the air gap becomes small relative to the resistance of the

enclosure and pipe insulation.

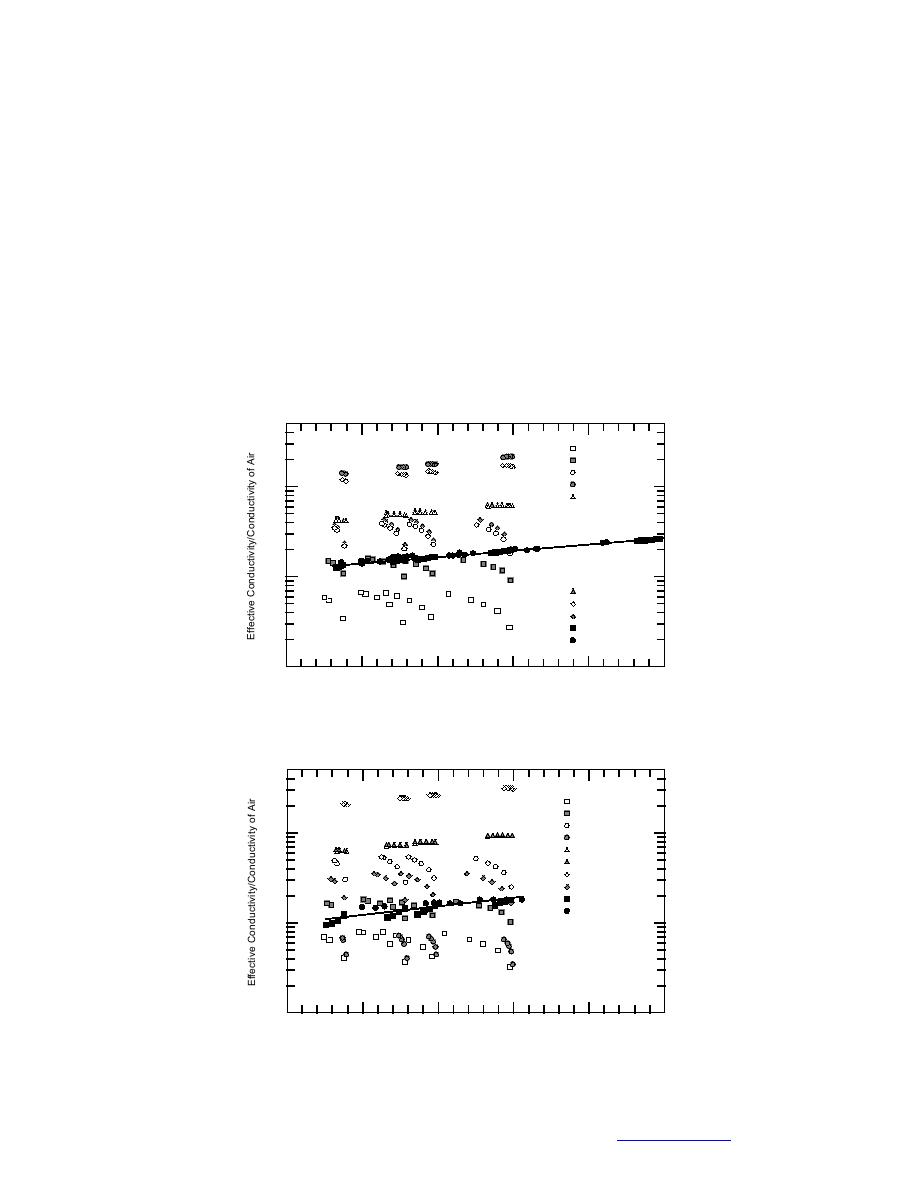

Figures 3942 compare the ratio of effective conductivity to the thermal conduc-

tivity of air (keff/kair) with the average temperature of the interior surfaces. The

effective conductivity was calculated using eq 36 and the heat flow through the

inside surface. Good agreement is seen between the numerical and experimental

test data, while comparison of the Table 1 methods, in some cases, shows effects of

temperature difference. Some of the methods show the same trend as the numerical

and experimental data but differ in magnitude (for example, method 4 in Fig. 42).

150

Method 1

Method 2

Method 3

Method 4

100

Method 5

10

Method 6

Method 7

Method 8

Numerical

Experimental

1

0

50

100

150

200

250

Average Temperature of Inside Surfaces (F)

Figure 39. Ratio of effective conductivity to the conductivity of air vs.

the average interior temperature (4-in. pipe).

150

Method 1

Method 2

Method 3

100

Method 4

Method 5

Method 6

Method 7

Method 8

Numerical

Experimental

10

0

0

50

100

150

200

250

Average Temperature of Inside Surfaces (F)

Figure 40. Ratio of effective conductivity to the conductivity of air

vs. the average interior temperature (2-in. pipe).

41

Back to Contents

Previous Page

Previous Page