0.8

0.6

0.4

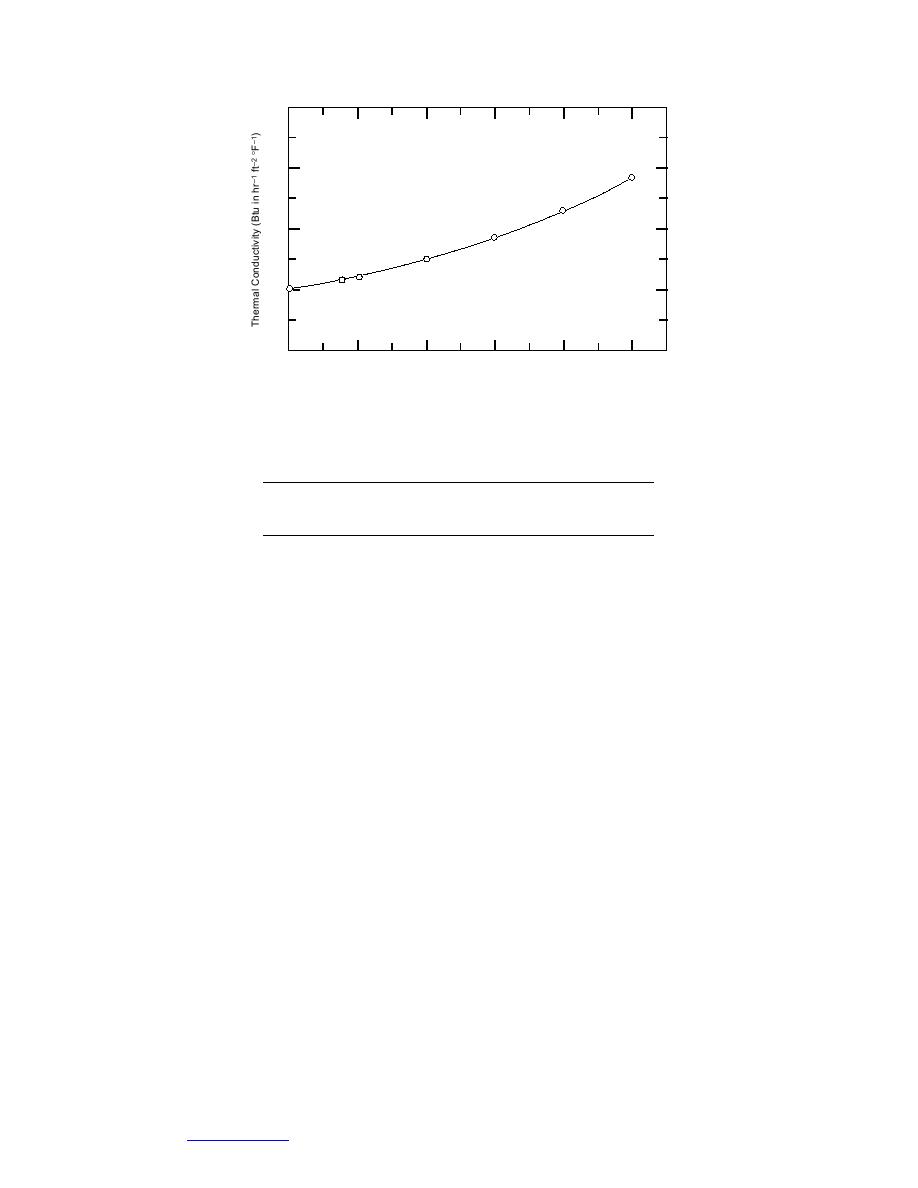

K = 0.196851 e0.0021168(T)

0.2

0.0

0

100

200

300

400

500

Mean Temperature (F)

Figure 17. Thermal conductivity of fiberglass pipe insulation.

Table 5. Test apparatus configurations.

Enclosure size

Nominal pipe diam.

Pipe treatment

1 ft 1 ft

4 in.

uninsulated, painted* , insulated

2

uninsulated, insulated

2 ft 4 ft

8, 4

insulated

* The uninsulated pipe was painted with a low-emissivity paint (Rust-

Oleum Aluminum No. 7715).

sure. Unfortunately, CRREL had at this time recently done away with its extreme

low temperature capability for environmental reasons.

Several years after these initial experiments, CRREL regained its extreme low

temperature brine capability and the apparatus was moved and replumbed to take

advantage of a coolant as low as 70F. Prior to resuming experiments, the inte-

rior surface-mounted thermocouples were replaced with 30-gage surface-mount

thermocouples in order to measure the surface temperatures more accurately.

Once experiments were resumed, further experiments were conducted using

the uninsulated 4-in. pipe. When these were completed, experiments continued

with various pipe treatments and configurations. Figure 17 is a plot of the thermal

conductivity of the fiberglass pipe insulation used. Table 5 summarizes the test

apparatus configurations.

The second apparatus was constructed similarly; however, no plywood sepa-

rated the cooling panels from the insulation, and a metal interior frame was used

to help support the cooling panels. Figure 18 shows the 2-ft 4-ft apparatus prior

to installing the lid. Figure 19 shows a cross section with dimensions and pipe

locations.

Data acquisition system

Two different data acquisition systems were used, one for the 1-ft 1-ft enclo-

sure and another for the 2-ft 4-ft enclosure; type-T thermocouples were used to

measure temperature, and a power meter was used to measure the power sup-

plied to the pipes.

For the 1-ft 1-ft enclosure, a personal-computer- (PC-) based data acquisition

system was assembled using an 80286 processor-based computer in conjunction

26

Go to Contents

Previous Page

Previous Page