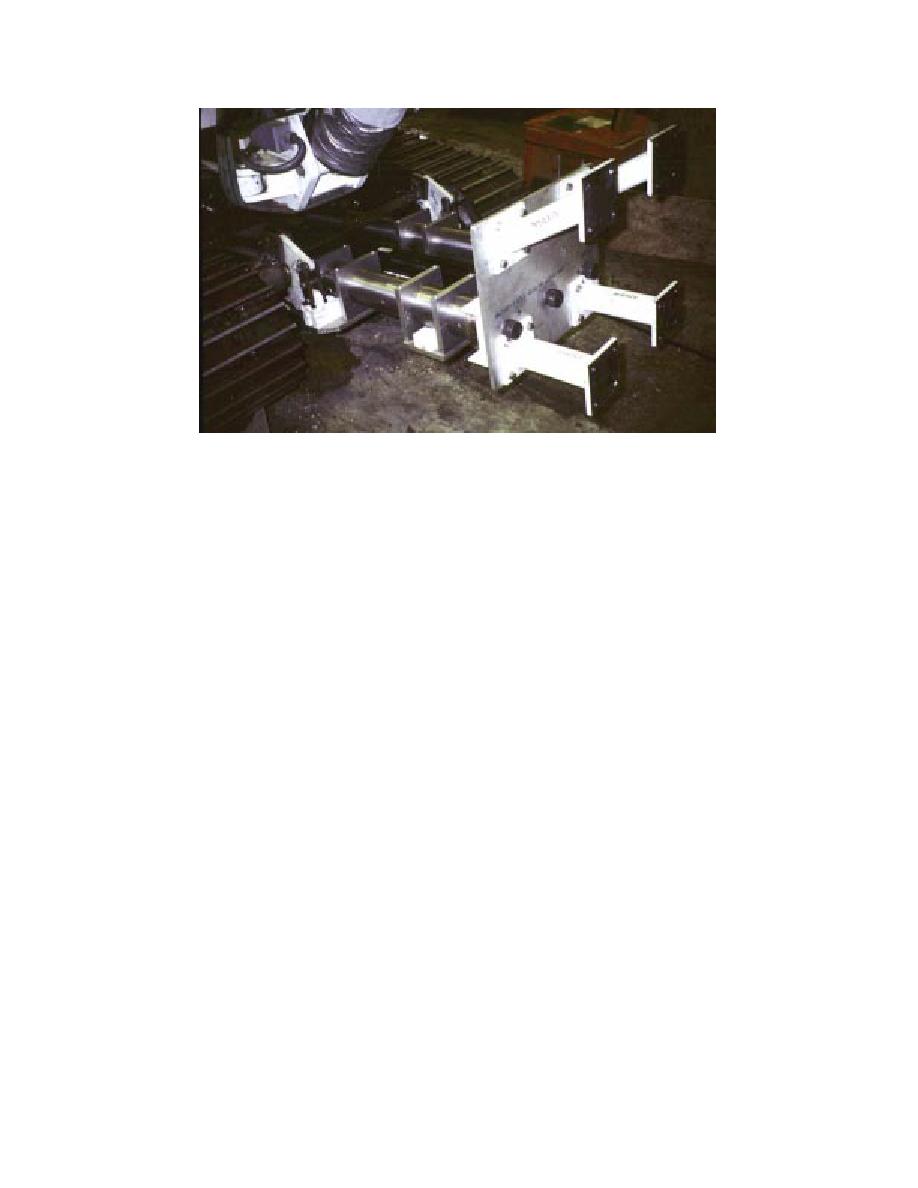

Figure 22. New snowblower frame.

promises the ability of the fan to process the ma-

with a V-groove band clamp system at this time.

terial. The solution was to add a 3-m sliding tube

This system is similar to the one used on the hori-

between the elbow and the blower to allow

zontal ducting. The redesign should prevent acci-

remixture of the material in the air stream. An

dental release of the tubes such as occurred sev-

additional benefit is increased ease of installation,

eral times during the tunneling operation. The

as this provides a radial degree of freedom in lo-

lifting bale for the vertical tubing was also replaced

cating the blower in relationship to the elbow.

with a simpler, easier-to-use system. Both changes

A new snowblower frame was installed (Fig.

will result in safer operations.

22), replacing the previous unit that did not ex-

The cutter drum was disassembled and rebuilt.

tend far enough and was not rugged enough. Two

The cutters were realigned to allow engagement

every 15, rather than every 45. A larger, special

bell cranks are used to lift the frame, putting the

lift cylinders in compression rather than tension

low-temperature chain was installed (no. 100 vs.

and thus reducing the chance of failure. The piv-

no. 80) as the previous chain had once again galled

ots are 3.8 cm diam., a substantial increase over

and no longer flexed freely. The 12.7-mm hydrau-

the previous 1.6-cm diam. pivot pins, and the as-

lic lines were replaced with 15.9-mm lines, cutting

sembly is lifted from two points rather than one,

line losses in half. The drum and snowblower

adding to the strength and stability of the unit.

pumps were replaced with more robust, higher

The horizontal duct assemblies were modified

capacity pumps, thus increasing the availability

to increase ease of use. The original extension

of speed and torque. Cavitation due to inad-

stops, which did not function as planned, were

equately sized suction lines prevented the comple-

removed and cable stays were added to prevent

tion of this task, however, although some simpli-

overextension of the tubes. Polyethylene was

fication of the hydraulics was carried out.

added to the tubes to decrease friction and galling

A few smaller modifications aimed at ease of

during relative movement between tubes. Col-

use were also made. The tilt indicators were repo-

lapsed-length stops were also added to prevent

sitioned to read "0" on the flat and level, and the

compression of the tube seals, and the trucks were

inclination directions changed to be more intui-

tied together with cables to reduce the stress on

tive ("+" is now up, "" down). The accumulator

the system when advancing after full extension.

valve for the tunneler was replaced, restoring func-

The force of extension will now be taken up pri-

tionality to the joystick controls. With these and

marily by the cables rather than the components

the other modifications noted in this section, op-

of the pup truck and duct assemblies.

eration and production of the tunneling system

The vertical ducting fasteners were replaced

should be much improved.

20

Previous Page

Previous Page