determine the optimal method of achieving mini-

start from scratch and troubleshoot every suspect

mal percolation rates into the pad. With a 15-cm

component in the system. The following is a list

layer of compacted peaty silt lining the basin, per-

of problems uncovered and actions carried out to

colation rates were low enough (<105 cm/s) to

resolve them.

be acceptable for use. The basin was instru-

mented to monitor water level, sediment and air

Flexible hose sections

temperature, and sediment moisture, parameters

Due to poor construction, end connectors on

critical to the remediation process for WP.

the 25-cm-diam. hose sections failed on a regular

basis. All the flexible hose sections in the spoils

line were removed and replaced with short sec-

INITIAL DEPLOYMENTS

tions of rigid PVC pipe. After one section of PVC

Initial deployment of the dredge took place in

pipe blew an end fitting, the number of screws

October of 1994 (Walsh et al. 1996). Due to the

holding the fittings to the pipe ends was doubled

lateness of the season and delays caused by im-

from two to four. No further problems were

properly running equipment, very little dredging

encountered.

was accomplished. Enough spoils were pumped

for only two composite samples, one of which

Sensors

was heavily contaminated. However, results

Closer examination of the dredge function

demonstrated that an operable dredge system

feedback sensors (intake suction, pump output

will effectively remove contaminants from the

pressure, system hydraulic oil pressure, and cen-

environment.

trifugal pump hydraulic oil pressure) indicated

Early in the 1995 dredging season, a number of

that the output signal range was from 1 to 6 VDC,

improvements were made to the equipment, but

not the 05 VDC specified in the contract. This re-

problems continued to plague the operation. Ini-

sulted in miscalibration and the clipping of the

tial dredging operations were quite discouraging,

higher signal output (56 VDC). In addition, the

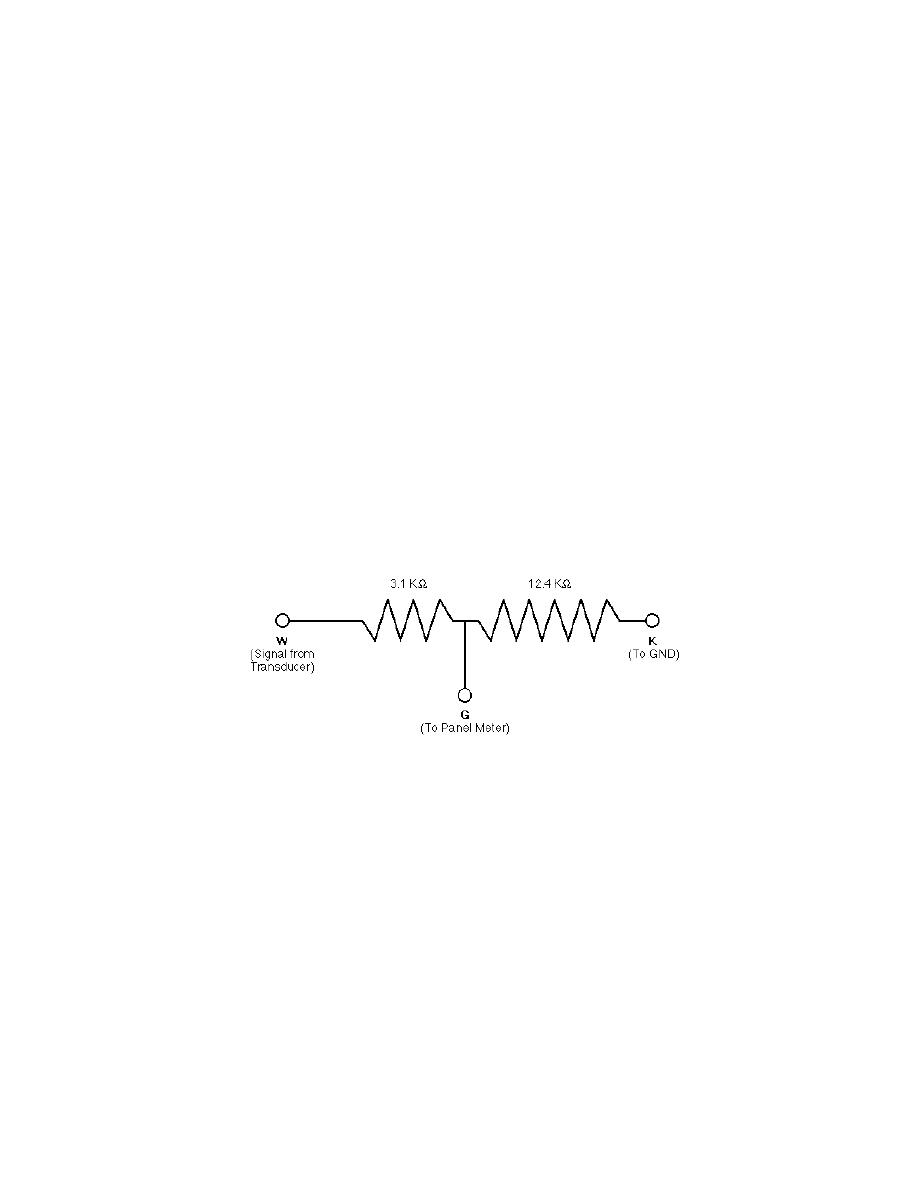

Figure 5. Sensor voltage divider (typ. each sensor).

showing little improvement over the previous

sensors were wired to the wrong inputs on the

season. Output from the various dredge sensors

video panel meter that transforms the sensor sig-

was still unusable, reading below known maxi-

nals into output data for transmission over the

mum system values at full operating conditions,

video system. These were rewired to the correct

and the pump was not operating correctly. Top

inputs. A voltage reduction circuit using preci-

speed was attained at about 50% of hydraulic

sion resistors was designed at CRREL and in-

throttle, and spoils flows could not be main-

stalled between the sensor output leads and the

tained. In addition, the 25-cm-diam. flexible sec-

video panel meter (Fig. 5). This circuit attenuates

tions in the spoils line continued to blow fittings.

the signal 20%, resulting in an input signal of 0.8

Consultations with the equipment manufacturer

to 4.8 VDC to the panel meter. Voltages now cor-

did not result in a solution, and discussions with

responded to the range of the panel meter, 05

the pump manufacturer and an engineer at the

VDC. The panel meter was reprogrammed and

Waterways Engineering Station in Vicksburg

pumping tests rerun to obtain data for pump

indicated that a second look at the pump was

evaluation.

warranted.

After two unsuccessful attempts at using the

Pump

system as configured, the decision was made to

With the sensors wired correctly and recali-

4

Previous Page

Previous Page