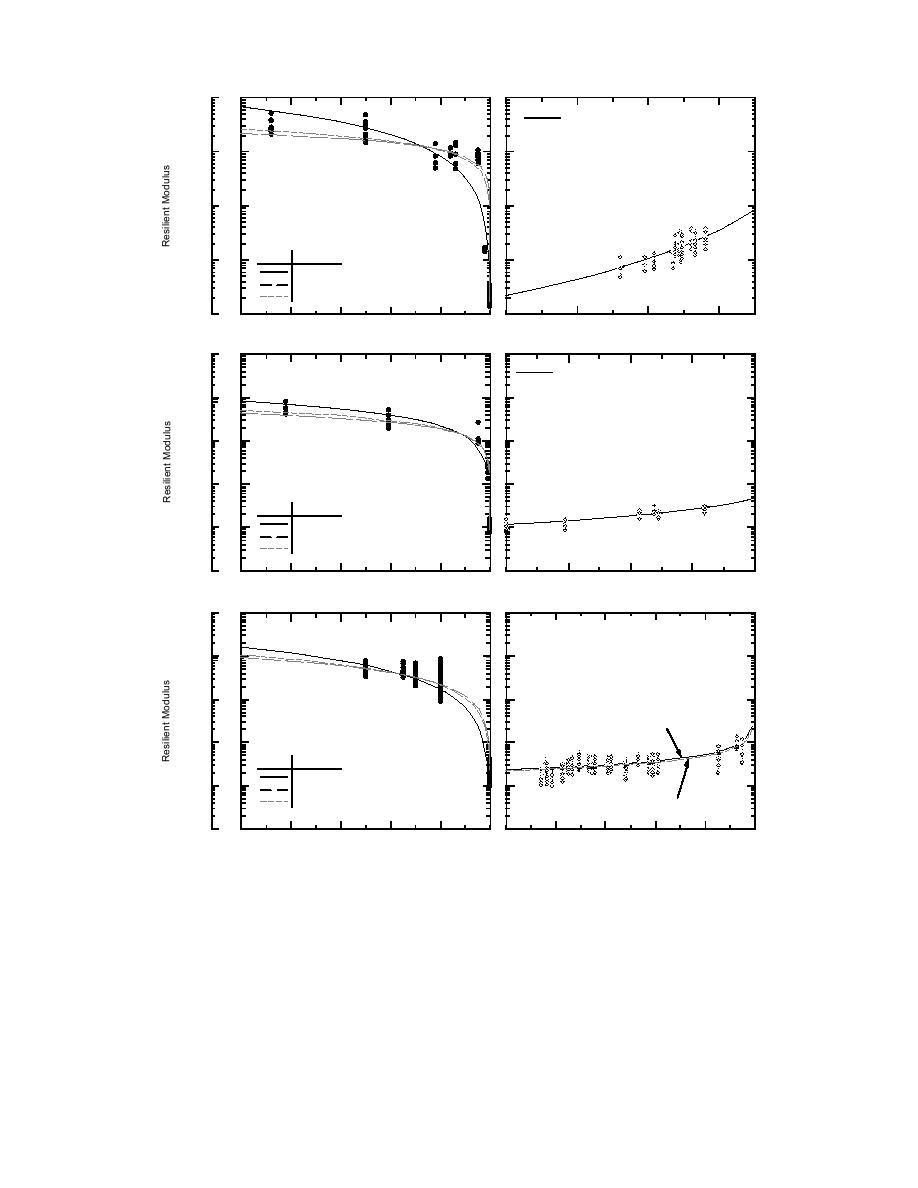

(kPa) (lb/in.2 )

107

7

7 x10

d

Calculated

7 x 106

106

105

7 x 105

Calculated

4

7 x 104

10

wu/w t

wu-g

Class 4 Subbase

wu-v

Albany Taxiway A

3

3

10

7 x 10

-10

-8

-6

-4

-2

0 100

80

60

40

Temperature (C)

Degree of Saturation (%)

(kPa) (lb/in.2 )

8

8

10

7 x10

e

Calculated

107

7 x 107

106

7 x 106

105

7 x 105

Calculated

104

wu/w t

7 x 104

wu-g

Class 5 Subbase

wu-v

Dense-graded Stone

103

7 x 103

-10

-8

-6

-4

-2

0 100

80

60

40

20

Temperature (C)

Degree of Saturation (%)

(kPa) (lb/in.2 )

8

7 x108 10

f

107

7 x 107

106

7 x 106

Calculated, Log Log

105

5

7 x 10

Calculated

wu/w t

104

7 x 104

wu-g

Calculated, Semi Log

wu-v

Class 6 Base

103

7 x 103

0 100

80

60

40

20

0

-10

-8

-6

-4

-2

Temperature (C)

Degree of Saturation (%)

Figure 14 (cont'd). Frozen and unfrozen modulus data compared with calculated moduli

from predictive equations.

The right-hand graphs in Figure 14 show the

Also shown is a line representing the predicted

resilient modulus data vs. degree of saturation for

resilient moduli resulting from the equations given

the unfrozen specimens. For the two subgrade

in Table 1, at the mean stress level tested. Where

materials, data are from specimens that were never

dry density is included in the equation, it was set

frozen; data from the base materials are from speci-

at the average value of all specimens tested. It can

mens that were thawed subsequent to freezing.

be seen in Figure 14 that moisture level does in-

24

Previous Page

Previous Page