Burmeister's solution

Burmeister (1982) combined eq 16 and 17 into a single equation and obtained an

approximate analytical solution for it. His solutions for the tip temperature θ(0), heat

transfer rate q, and fin efficiency are

θ (0) = 1/ cosh F

(30)

(

)1/7 tanh6/7 F

q = 1.8263kl (Tsat - Tfb ) F1F2

3

(31)

6/7

tanh F

η=

(32)

F

where

(

)1/8 .

F = 1.038 F1F2

4

(33)

The efficiency values predicted by eq 32 are in close agreement with the values given in

Table 2.

Archarya et al. solution

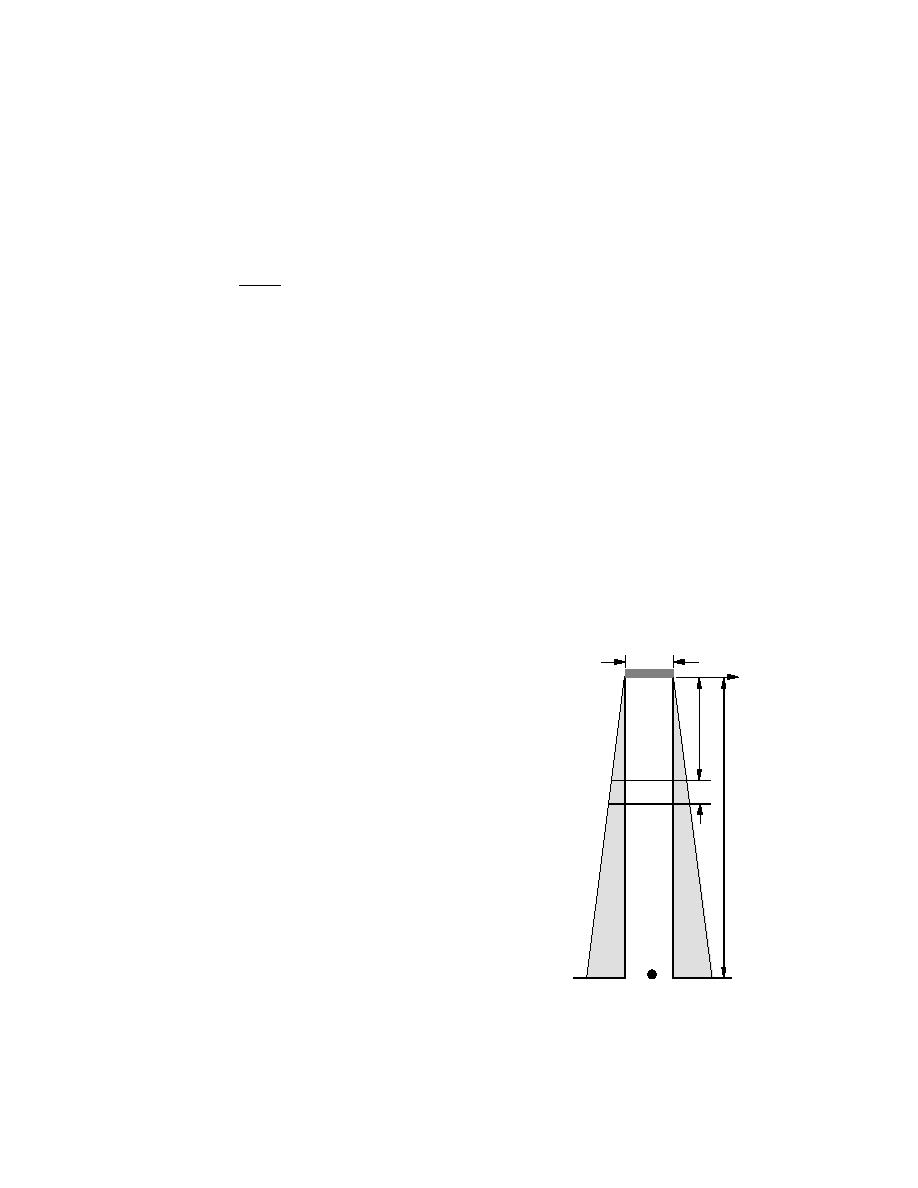

Archarya et al. (1986) considered vertical fins (Fig. 6) of seven profile shapes, namely

rectangular, triangular, trapezoidal, concave parabolic, convex parabolic, cylindrical and

conical. For each geometry, they solved eq 13 and 14 numerically and obtained the results

for η. For all seven shapes, the efficiency could be represented by a simple relationship of

the form

η = η0.855

(34)

c

where ηc is the efficiency of the fin calculated from classical one-dimensional fin theory

and assuming the heat transfer coefficient to be con-

w

stant for all shapes, its value being given by eq 24.

y

in Kern and Kraus (1972).

X

Improved conjugate model

Kazeminejad (1993) improved the simple conju-

gate model described by eq 1618 by including the

dx

Saturated

effect of vapor velocity. As expected, the effect of

Vapor, Tsat

L

vapor shear was to reduce the condensate film thick-

ness and hence increase the fin surface temperature.

kf

The heat transfer to the fin and its capability to sup-

port condensation is considerably enhanced.

Patankar and Sparrow (1979) considered film con-

Film

densation on a vertical rectangular fin, which is at-

tached to a cooled vertical base at temperature Tfb

(Fig. 7). The fin has length L, thickness w and depth

Tfb

H, and is made of a material with thermal conduc-

tivity kf. The fin is immersed in a pure saturated

Figure 6. Condensation on a vertical

vapor at temperature Tsat (> Tfb).

fin of rectangular profile.

11

Previous Page

Previous Page