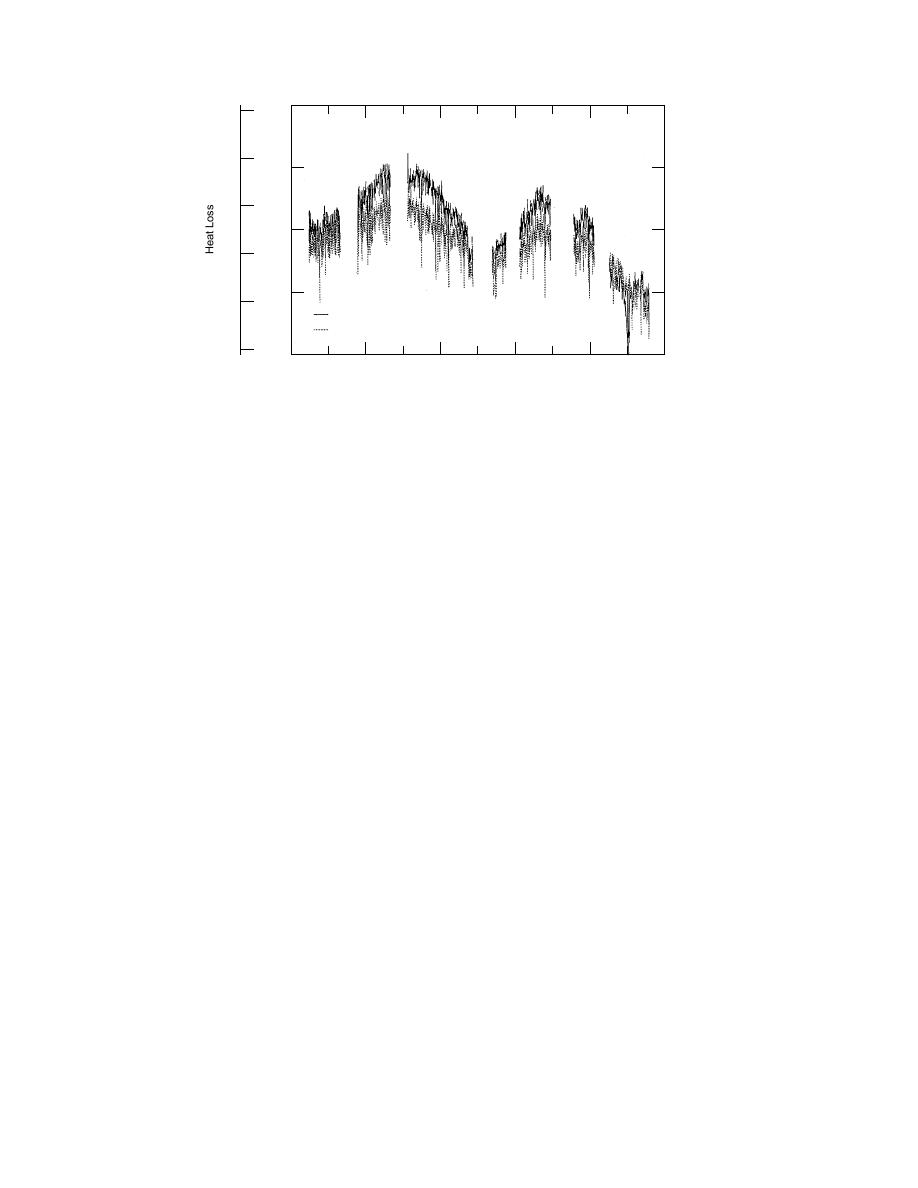

(Btu / hr - ft) (W / m)

35

36

32

30

28

25

24

20

20

Soil Method

I

nsulation Method

16

15

06 - 01 - 89

12 - 01 - 89

06 - 01 - 90

12 - 01 - 90

06 - 01 - 91

12 - 01 - 91

Date

Figure 14. Heat losses from the LTHW site 2 system.

the supply and return piping is approximately

Conclusions drawn from

150 mm (6 in.) in diameter with approximately 32

heat loss measurements

The objective of our heat loss studies has been

mm (1.25 in.) of polyurethane foam insulation.

to achieve some insight into several aspects of

The average value of the heat loss from this sys-

thermal analysis of heat distribution systems. Of

tem using the two methods of measurement de-

primary importance is the actual rate of heat losses

scribed earlier is about 37.5 W/m (39 Btu/hr-ft).

from operating heat distribution systems. We have

For the medium temperature hot water system at

presented several years of data for five different

Ft. Jackson, South Carolina, the common conduit

sites on four types of heat distribution systems. In

site has approximately 125-mm (5-in.)-diameter

all but one case these heat losses have been mea-

supply and return piping with about 38 mm (1.5

sured under actual field conditions by more than

in.) of mineral wool insulation. The heat losses of

one method. By making heat loss calculations us-

this system average 108.6 W/m (113 Btu/hr-ft)

ing several different methods using independent

using the average of the three different methods

measurements, we have established the validity

of measurement described earlier. With proper

of our techniques for systems similar to those

design, the 150 mm (6-in.) low temperature pip-

studied. The methods used to make these mea-

ing is able to convey as much heat as the 125 mm

surements have proven to be very reliable and

(5-in.) medium temperature water piping. An ex-

repeatable. In general, agreement between meth-

ample of the heat carrying capacity is given in

ods has been very good in terms of the magnitude

Phetteplace (1992). Thus, the losses are reduced

of the heat losses as well as the trends over the

by a factor of nearly three. To put this in per-

yearly cycle.

spective, consider what this would do to the heat

The relative levels of heat losses found in our

losses from the Army's 5600 km (3500 mi) of heat

studies give rise to some significant conclusions re-

distribution piping (U.S. Army 1992). At 108.6

garding the cost of heat losses for the DoD and our

W/m (113 Btu/hr-ft) and .48 per GJ ( per

ability to impact these costs. We can use these re-

million Btu) the annual cost of heat lost would be

over 2 million. For 37.5 W/m (39 Btu/hr-ft)

sults to make an estimate of heat loss costs for DoD

and the same cost of heat the annual cost of heat

and also the savings which could be achieved by

losses would be about million. Thus, the Army

converting our high temperature water and steam

could save nearly 0 million per year from heat

systems over to low temperature hot water.

that is now lost to the environment. This assumes,

As an example, consider the reduction in heat

of course, that all the existing systems have rates

losses possible with low temperature water as

of heat loss similar to those of the Ft. Jackson

illustrated by some of the measurements taken on

system. Assuming that the size of the Ft. Jackson

the Ft. Irwin system. At one of the Ft. Irwin sites

22

Previous Page

Previous Page