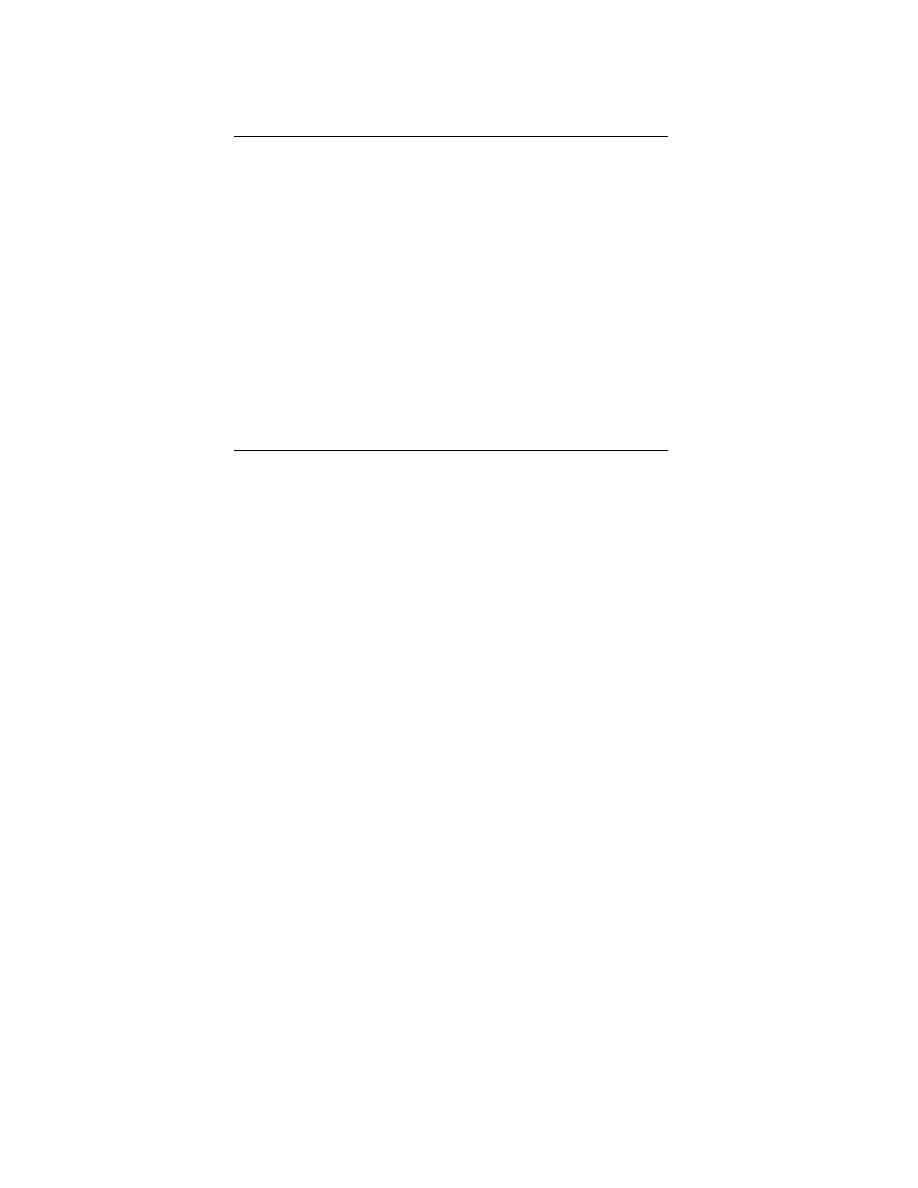

Table 5. Recommended solvent rinses for soluble contaminants (from

U.S. EPA 1991).

Solvent

Soluble contaminants

Water

short-chain hydrocarbons

inorganic compounds

salts

some organic acids

some polar organic compounds

Dilute acids

basic (caustic) compounds

amines

hydrazines

Dilute bases (detergent, soap)

metals

acidic compounds

phenols

thiols

some nitro and sulfonic compounds

Organic solvents, e.g., alcohols,

nonpolar organic compounds

ethers, ketones, aromatics,

straight-chain alkanes (e.g.,

hexane), common petroleum

products (e.g., fuel oil, kerosene)

thoroughly with potable water, 3) rinse with deion-

instead of a dilute nitric acid rinse when cleaning

ized or distilled water, and 4) air dry. For grossly

stainless steel. They stated that this was because

contaminated equipment they recommended the

nitric acid may oxidize steel. However, any acid

following protocol: 1) wash with detergent solu-

solution can corrode a stainless steel surface

tions and rinse with potable water, 2) rinse with

(Driscoll 1986). For glass and polymeric surfaces,

an organic solvent (preferably isopropanol), 3)

the purpose of an acid rinse is to remove sorbed

wash with a detergent solution a second time and

metal ions from the surface. This procedure

rinse with potable water, 4) rinse with deionized

would be of questionable effectiveness for any

or distilled water, and 5) air dry. They cautioned

metal surface.

that this equipment should not be used to sample

Region IV of the U.S. EPA (U.S. EPA Region IV

water suspected of being contaminated at low or

1991) recommended different protocols for clean-

trace levels. However, they did not supply any

ing equipment used to collect samples for trace

data to back up either of these recommended

organic compounds and metals, depending upon

methods.

the material being cleaned. For fluoropolymers

The U.S. EPA (1991) gives different recommend-

(Teflon) and glass they recommended an acid

ed solvent rinses for various contaminants (Table

rinse, but for stainless steel and other metal sam-

5). However, the list of recommended organic sol-

pling devices they did not. They did not explain

vents for removing nonpolar organic contami-

why these methods differed. They also gave dif-

nants is general, and it is doubtful whether a num-

ferent protocols for precleaning various types of

ber of the solvents they recommend should be

sampling tubings. They recommended that stain-

used. For example, fuel oil or kerosene can both

less steel tubing receive a detergent wash and rinse

be target analytes.

with high-quality water and a rinse with (an un-

When sampling for organics, draft guidance by

specified) organic solvent. Silastic rubber tubing

the U.S. EPA for RCRA sites (U.S. EPA 1992) rec-

would receive a similar wash but would not be

ommends two solvent rinses: one with hexane or

rinsed with organic solvent. In this case, the rea-

methanol, followed by a rinse with acetone, fol-

son is probably because the rubber tubing would

lowed by a rinse with organic-free reagent water.

be degraded by most organic solvents. The glass

When sampling for metals, this document also rec-

and Teflon tubings receive only an organic sol-

ommended using a dilute hydrochloric acid rinse

vent rinse, followed by air drying for the glass

9

Previous Page

Previous Page