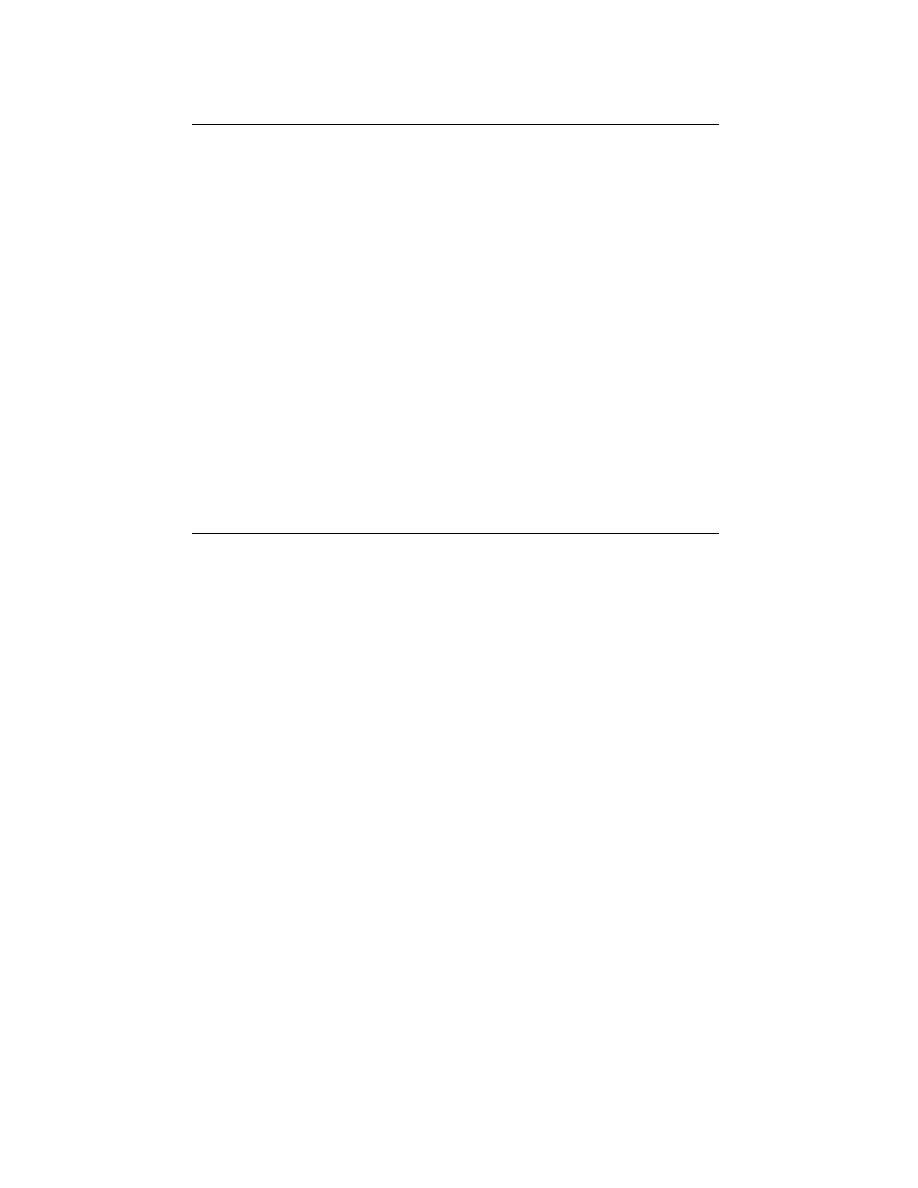

Table 3. Decontamination solutions for drilling equipment (from Moberly 1985).

Chemical

Solution

Uses/remarks

Sodium carbonate

4 lb/10 gal water

Neutralize organic acids, heavy metals, and

metal processing wastes

Sodium bicarbonate

4 lb/10 gal water

Neutralize either base or acid (baking soda)

contaminants

Trisodium phosphate

2 lb/10 gal water

Similar to sodium carbonate.

(TSP, Oakite)

4 lb/10 gal water

Good for solvents and organic compounds

(such as toluene, chloroform, TCE, PCBs)

Calcium hypochlorite

8 lb/10 gal water

Disinfectant, bleaching, and oxidizing agent.

(HTH)

Used for pesticides, fungicides, chlorinated

phenols, dioxins, cyanides, ammonia, and

other nonacidic inorganic wastes.

Hydrochloric acid

1 pt/10 gal water

Used for inorganic bases, alkali and caustic

wastes

Citric, tartaric,

4 lb/10 gal water

Used to clean heavy metal contamination.

and oxalic acids

(or their respective

salts)

Organic solvents

Concentrated

Used to clean equipment contaminated with

(e.g., acetone, metha-

organics or surface oils.

nol, methylene

chloride)

CURRENT PROTOCOLS FOR

Chemical neutralization methods

A number of chemicals can be used to neutral-

DECONTAMINATING

ize various organic contaminants. Although this

approach is not commonly used to decontaminate

SAMPLING DEVICES

sampling devices used for monitoring groundwa-

Commonly, guidelines for decontaminating

ter, the military has found this approach neces-

sampling devices (e.g., U.S. EPA 1992) suggest that

sary when decontaminating surfaces contaminat-

equipment be decontaminated by first washing

ed with neat chemical warfare agents. Moberly

with a nonphosphate detergent, then rinsing with

(1985) outlined a number of chemicals that could

tap water, rinsing with (high-quality) acids and

be used for decontaminating drilling equipment

solvents, rinsing with some type of high-quality

(Table 3). Bleaching agents include calcium hy-

water (e.g., distilled, deionized, organic-free re-

pochlorite (HTH), Super Tropical Bleach (STB),

agent water), and finally air drying. Washing with

and household bleach. Bleaches can degrade and

detergent and water removes gross contamina-

detoxify many of the more toxic contaminants,

tion and particles, an acid rinse desorbs inorganic

such as organo-phosphorus pesticides (Esposito

contaminants, a rinse with organic solvents re-

et al. 1985). Two problems with this type of ap-

moves less polar organic contaminants, and the

proach are that many of these decontaminants

final high-quality water rinse removes the acid

are hazardous to work with and they may de-

solutions and/or organic solvents.

grade the surface being decontaminated. For ex-

Almost all methods recommend either using a

ample, bleaches can corrode metal equipment.

nonphosphate (e.g., ASTM 1990, U.S. EPA 1992)

Thus, this approach is really only applicable for

or a laboratory detergent (e.g., U.S. EPA Region

extreme cases where one encounters high levels

of very toxic contaminants or where other clean-

IV 1991), or both. Although the surfactants used

in detergents can be cationic, anionic, amphoter-

ing methods have proven ineffective in reducing

ic, or nonionic, there has been little discussion of

contaminant levels.

7

Previous Page

Previous Page