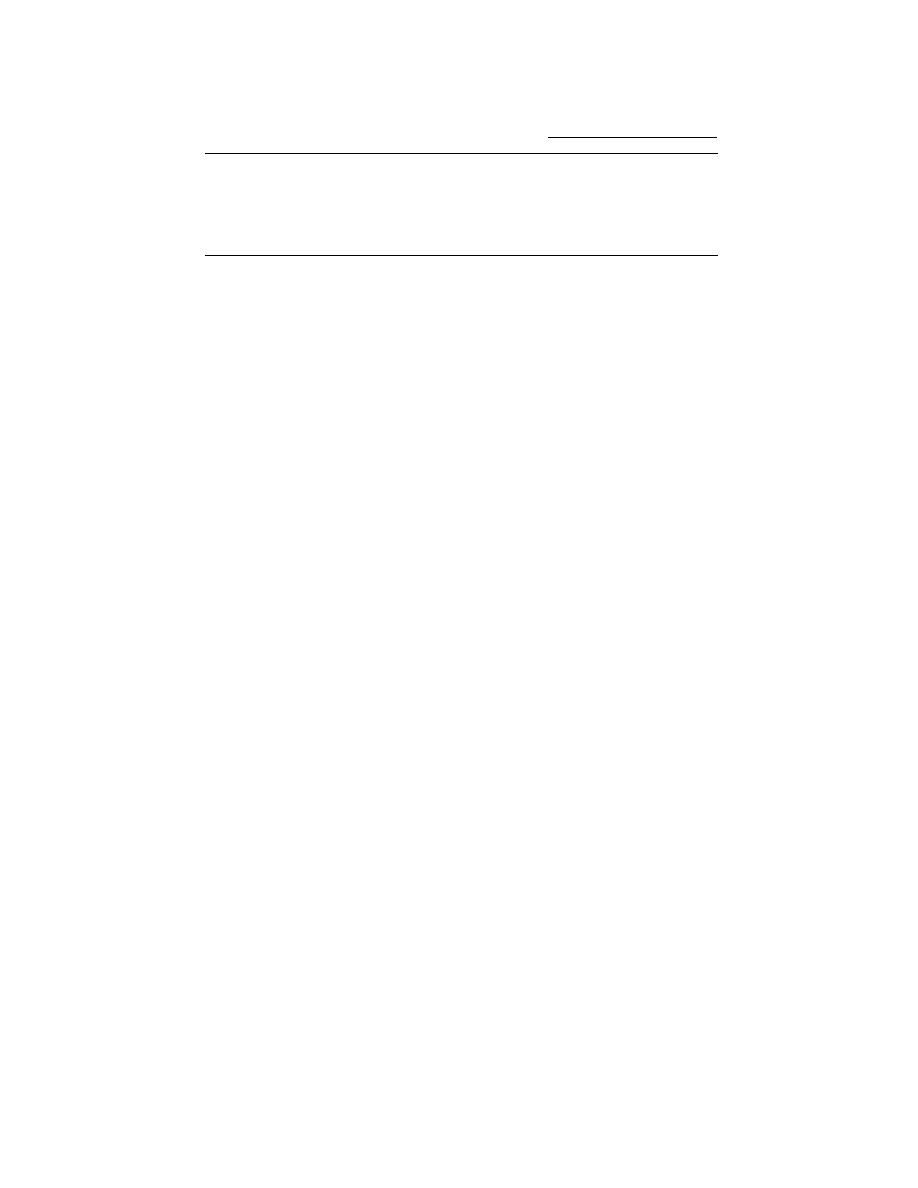

Table 4. Properties of four detergent solutions.1

Recommended (%) conc's, for

% phosphate

Type of

pH of

different water temps

Detergent

(as P)

detergent

1% sol.

Cold

Warm

Hot

1†

Alconox

7.3

anionic

9.5

1

1*

1†

Liquinox

0

anionic

8.5

1

1*

23*†

Detergent 8

0

nonionic

11.0

35

23*

2†

Citranox

0

**

2.52

2

2**

1

Information provided by Alconox, Inc.

* Recommended rinse temperature

† For hard-to-remove contamination, use higher concentrations

** Citranox is a blend of organic acids, anionic and nonionic surfactants, and alkolamines.

which type of nonphosphate or laboratory deter-

Variations in methodology

gent to select. Presumably it was thought that if

Mickam et al. (1989) compared the decontami-

the detergent removes similar contaminants from

nation procedures of several state and federal reg-

similar types of surfaces in the laboratory, it

ulatory agencies and found that these procedures

ought to work in the field. ASTM Method D-5088-

were highly variable. Following is a discussion of

90 (ASTM 1990) recommends using a nonphos-

some (but not all) of the variations that have been

phate detergent and refers to Alconox and Liqui-

found.

nox by name. Several other methods also refer to

While most methods did not stipulate how

Alconox. However, according to the manufactur-

aqueous cleaning was to be conducted (i.e., soak-

er, Alconox is not phosphate-free. Several other

ing, scrubbing with a brush, or using a high-pres-

detergents (Liquinox, Citranox, and Detergent 8)

sure washer), a few methods [ASTM 1990, U.S.

made by the same manufacturer (Alconox, Inc.)

EPA Region IV 1991, and according to Mickam et

are phosphate-free. Table 4 summarizes the char-

al. (1989) older procedures for Alabama and Penn-

acteristics of these detergents. All four of them

sylvania] did recommend using a brush during

can be used for soaking, brush cleaning, ultrason-

the cleaning process. In the past, a few state agen-

ic cleaning, and flow-through cleaning in place

cies have also recommended using either steam

(as would be used for a pump), but only Deter-

cleaning [California, New Jersey, and New York

gent 8 is recommended for spray cleaning. The

according to Mickam et al. (1989)], or a power

manufacturer recommends two phosphate-free

washer [Maryland and New Jersey according to

detergents, Liquinox and Detergent 8, for clean-

Mickam et al. (1989)] either to remove gross con-

ing equipment that will be used for environmen-

tamination or for equipment used for collecting

tal sampling and testing.

samples to be analyzed for organic contaminants

Typically, the acid rinse is dilute (0.1 N) hydro-

(California). Region IV of the U.S. EPA also rec-

chloric or nitric acid. Most protocols do not rec-

ommended steam cleaning when necessary (U.S.

ommend this step unless inorganic species are

EPA Region IV 1991). In addition, several research

going to be analyzed. Recommended organic sol-

studies (Bryden et al. 1986, Matteoli and Noonan

vents vary with the particular protocol but typi-

1987, Fink and Boyajian 1989) have used steam

cally include acetone, hexane, or methanol. Obvi-

cleaning to clean sampling equipment, and a pa-

ously, any organic solvent that is used as a rinsing

per by Brice and Kelley (1991) recommended us-

agent should not be one of the target analytes or

ing a high-pressure sprayer.

interfere with chemical analyses. In addition, the

Brice and Kelley (1991) give one of the most

waste decontamination fluids need to be disposed

descriptive and extensive protocols for aqueous

of properly and should be containerized, at least

cleaning of sampling devices. They recommend-

until it can be determined if the waste is hazard-

ed the following cleaning procedure for lightly

ous. Clearly, it is advantageous to find the most

contaminated equipment: 1) remove particles us-

effective decontamination method that generates

ing a low-volume, high-pressure sprayer, 2) scrub

the least amount of hazardous waste.

in a phosphate-free detergent solution and rinse

8

Previous Page

Previous Page