form have quite limited solubility in water, while

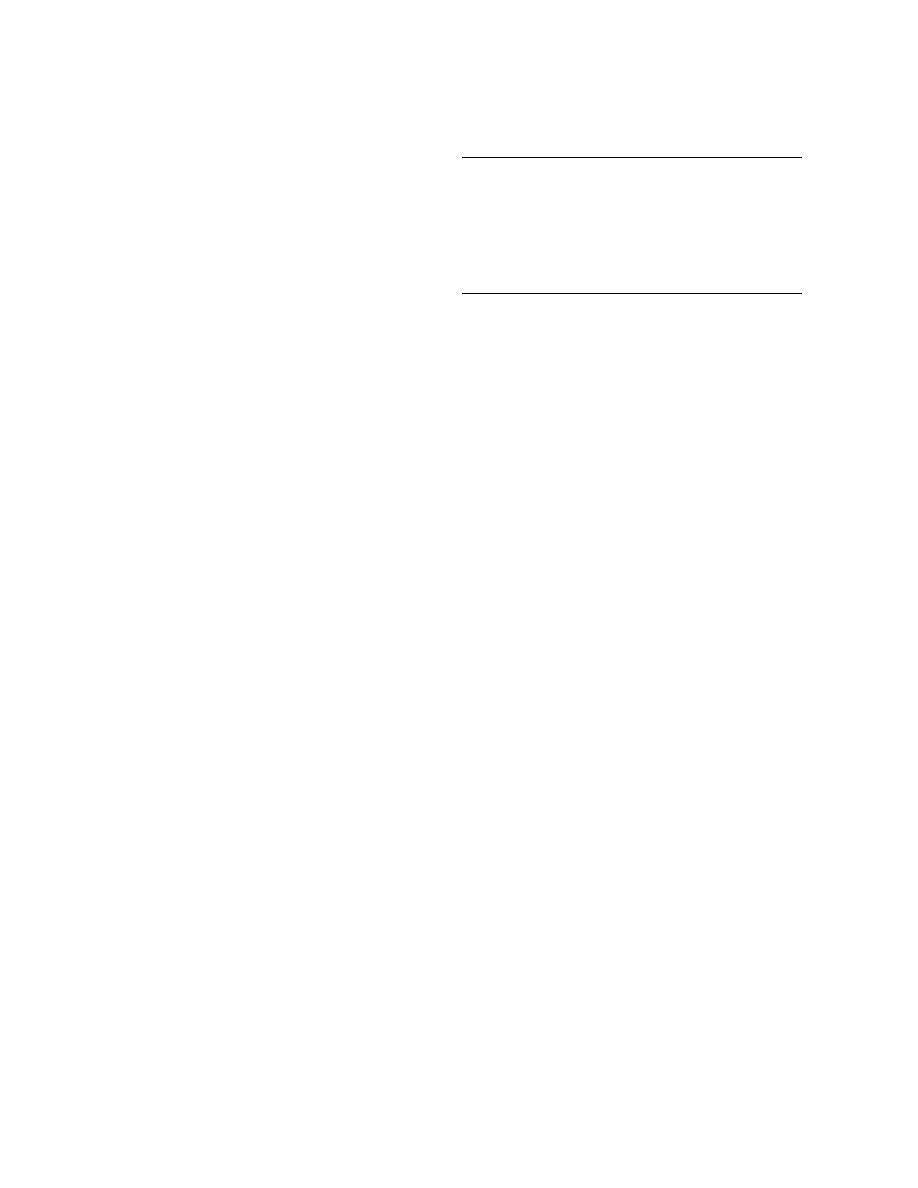

Table 1. Types of pressurized water systems (from Sum-

the micelles are highly soluble. Thus, ionic sur-

mers 1982).

factants will dissolve more readily and to a great-

Flow rate

er extent in heated water. The effects of tempera-

Type

Pressure

(L/min)

ture can be quite different for some nonionic

surfactants. For some nonionic surfactants, the

Low pressure

689 kPa

38 to 378

cmc has been found to decrease with increasing

(100 psi)

(10 to 100 gal/min)

temperature, and others are less soluble in hot

Intermediate pressure

3445 to 20,700 kPa

18.8 to 94.5

water than in cold.

(500 to 3,000 psi)

(5 to 25 gal/min)

The presence of other substances in the clean-

ing solution, such as ions (e.g., metals) or organic

High-pressure jets

68.9 to 138 MPa

18.8 to 94.5

contaminants, can also affect removal efficiencies.

(10,000 to 20,000 psi)

(5 to 25 gal/min)

According to Osipow (1962), electrolytes lower the

cmc and increase the size and alter the charge of

burns, corrosion of metal surfaces, and liberation

the micelles of ionic surfactants. Thus, electrolytes

of toxic vapors (if sufficient quantities are present).

increase the solubilization of nonpolar materials

With high-pressure water washers, high-pres-

and may increase or decrease the solubilization of

sure pumps produce solid water streams rather

polar materials, depending upon the compound

than the small droplets produced by steam clean-

being solubilized (Osipow 1962).

ing. The advantages over steam cleaning are that

In some studies there is mention of adding or-

there is increased force available and that the en-

ganic solvents to cleaning solutions to aid in the

ergy requirements are lower because water does

dissolution of sorbed organic contaminants. Al-

not have to be converted to steam. Summers (1982)

though not much data on the effectiveness of this

placed pressurized-water washing systems into

approach was found, some examples of organic

three categories: 1) those with relatively low pres-

solvents that have been used for this purpose in-

sure and high flow rates, 2) those with intermedi-

clude ethanol, acetone, and butanol. According to

ate pressure and flow rates, and 3) those with rel-

Osipow (1962), added organic compounds in-

atively high pressure jets and intermediate flow

crease the micelle volume of ionic surfactants, and

rates (see Table 1 for specific pressures and flow

the increased volume of this "pseudophase" is

expected to have an increased solvent action on

rates).

other organic materials. (Concentrations of exam-

Summers (1982) found that adding long-chain

ples given by Osipow were 0.1 to 0.3 moles/1000

polymers (such as Polyox [Union Carbide], Nalco

g surfactant.) Organic compounds may also af-

[Nalco Corp.], and Superwater [Berkley Chemi-

fect the cmc of surfactants. Long-chain alcohols

cal Corp.]) to the wash water improved perfor-

and amines will lower the cmc, and short-chain

mance. Although the function of these polymers

alcohols may increase or decrease the cmc de-

is not fully understood, Summers believed that

pending upon the temperature (Osipow 1962).

they reduced the flow resistance of the liquids and

maintained the integrity of the jet stream for a

Pressurized water cleaning

longer distance after it left the nozzle. The effi-

With steam cleaning, pressure developed in the

ciency of high-pressure water jets can also be en-

steam boiler imparts a high velocity to a mixture

hanced with other additives, such as abrasive or

of water droplets and steam, which is directed

nonabrasive particulates (abrasive cleaning),

from a nozzle onto the target surface. Detergent

surfactants, or other additives that affect the phys-

and heat from the steam weaken the bonds be-

ics of interaction between the liquid jet spray and

tween the dirt and surface while the high velocity

contaminant residue (Cante et al. 1980).

of the water droplets has sufficient power to re-

move the debris from the surface (Summers 1982).

Cleaning or rinsing with

Depending upon the contaminant, steam can also

organic solvents

facilitate volatilization, thermal decomposition,

Typically, organic solvents are used where 1)

and hydrolysis. Esposito et al. (1985) felt that long-

water is undesirable (e.g., for electrical and elec-

term exposure to steam should theoretically aid

tronic devices or where humidity might corrode

in the removal of subsurface contaminants as well.

neighboring equipment), 2) contaminants consist

Problems associated with steam cleaning include

of grease, tar, oil, and rosins, 3) fast evaporation is

5

Previous Page

Previous Page